Devising an innovative method for improving decision-making efficiency at polymers processing companies in automotive industry

DOI:

https://doi.org/10.15587/1729-4061.2024.317462Keywords:

decision-making, management methods, organizational innovations, polymer processingAbstract

Enabling the development of technologies for the production of polymer materials directly determines the possibility of achieving the standards of sustainable development in the automotive industry, since polymer composites are used in modern cars as components of almost all assemblies and mechanisms. The expansion of plastics application in the car structure contributes to the reduction of fuel consumption and wear of parts. Technological changes encourage enterprises to constantly improve decision-making methods regarding the introduction of innovative technologies.

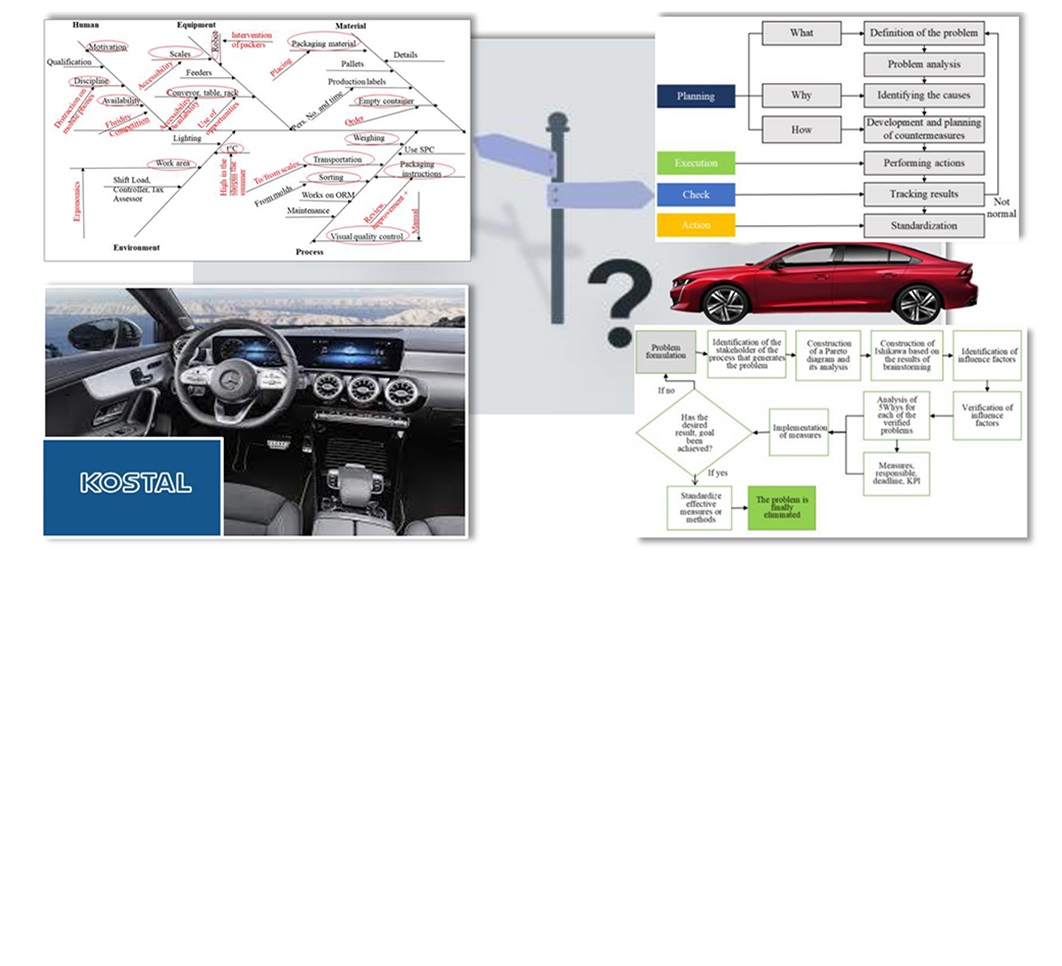

This paper reports an innovative method devised for making management decisions at enterprises specializing in the processing of polymers for the automotive industry, which makes it possible to increase production efficiency. Based on the Ishikawa diagram and the PDCA cycle application, management tools and procedures for making production and technological decisions have been developed using the methodology of finding root causes and verifying factors influencing existing production problem. A set of indicators that make it possible to reduce the number of management errors has been substantiated; they increase the reliability of verifying received intermediate results of decisions. The selection of verification indicators was carried out taking into account the specificity of polymer production technologies.

An improved decision-making management procedure is presented, which was embodied in an updated decision-tracking protocol. Unlike its basic version, it contains additional control points: target date of verification, date of verification, and result of verification. An experimental study showed that the application and observance of the full PDCA cycle increases the overall effectiveness of management by 63 %, which in turn has a positive effect on the company's sustainability in a competitive environment

References

- Directive 2000/53/EC of the European Parliament and of the Council of 18 September 2000 on end-of life vehicles - Commission Statements. Official Journal, L 269, 34–43. Available at: https://eur-lex.europa.eu/eli/dir/2000/53/oj

- Ganoshenko, E., Holik, Yu. (2018). Analysis of the problem of the formation and disposal of waste motor complex. Ekolohichni nauky, 2 (21), 40–45. Available at: http://ecoj.dea.kiev.ua/archives/2018/2/9.pdf

- End-of-life vehicles Regulation. Available at: https://environment.ec.europa.eu/topics/waste-and-recycling/end-life-vehicles/end-life-vehicles-regulation_en

- Saitarly, S., Plavan, V., Rezanova, N., Sova, N. (2018). Regulation of rheological and mechanical properties of polypropylene compositions for automotive parts. Technology Audit and Production Reserves, 6 (3 (44)), 9–13. https://doi.org/10.15587/2312-8372.2018.152056

- Prystynskyi, S. (2023). Adjusting the Performance Properties of Products Obtained by Injection Molding from Polyamide. Chemistry & Chemical Technology, 17 (4), 836–845. https://doi.org/10.23939/chcht17.04.836

- Ishikawa, K. (1984). Quality Control in Japan. The Japanese Approach to Product Quality, 1–5. https://doi.org/10.1016/b978-0-08-028160-5.50006-0

- Paulus, P. B., Kenworthy, J. B. (2019). Effective Brainstorming. The Oxford Handbook of Group Creativity and Innovation, 286–305. https://doi.org/10.1093/oxfordhb/9780190648077.013.17

- Serrat, O. (2017). The Five Whys Technique. Knowledge Solutions, 307–310. https://doi.org/10.1007/978-981-10-0983-9_32

- Cummings, J. A., Ballantyne, E. C., Scallion, L. M. (2015). Essential processes for cognitive behavioral clinical supervision: Agenda setting, problem-solving, and formative feedback. Psychotherapy, 52 (2), 158–163. https://doi.org/10.1037/a0038712

- Lead and Facilitate Root Cause Analysis that Leads Directly to Innovation. Available at: https://mgrush.com/blog/root-cause-analysis/

- Stefanovic, S., Kiss, I., Stanojevic, D., Janjic, N. (2014). Analysis of technological process of cutting logs using Ishikawa diagram. Acta Tehnica Corviniensis-Bulletin of Engineering, 7 (4), 93–98. Available at: https://acta.fih.upt.ro/pdf/2014-4/ACTA-2014-4-15.pdf

- Martela, F. (2019). What makes self-managing organizations novel? Comparing how Weberian bureaucracy, Mintzberg’s adhocracy, and self-organizing solve six fundamental problems of organizing. Journal of Organization Design, 8 (1). https://doi.org/10.1186/s41469-019-0062-9

- Leksic, I., Stefanic, N., Veza, I. (2020). The impact of using different lean manufacturing tools on waste reduction. Advances in Production Engineering & Management, 15 (1), 81–92. https://doi.org/10.14743/apem2020.1.351

- Velasquez, M., Hester, P. T. (2013). An analysis of multi-criteria decision making methods. International journal of operations research, 10 (2), 56–66. Available at: http://www.orstw.org.tw/ijor/vol10no2/ijor_vol10_no2_p56_p66.pdf

- Laiker Dzhefri, K. (2017). Filosofiya Toyota. 14 pryntsypiv roboty zlahodzhenoi komandy. Kyiv: Nash format, 424.

- Inceoglu, I., Thomas, G., Chu, C., Plans, D., Gerbasi, A. (2018). Leadership behavior and employee well-being: An integrated review and a future research agenda. The Leadership Quarterly, 29 (1), 179–202. https://doi.org/10.1016/j.leaqua.2017.12.006

- Veliyath, R. (1992). Strategic planning: Balancing short-run performance and longer term prospects. Long Range Planning, 25 (3), 86–97. https://doi.org/10.1016/0024-6301(92)90373-a

- Yazdani, M., Zarate, P., Kazimieras Zavadskas, E., Turskis, Z. (2019). A combined compromise solution (CoCoSo) method for multi-criteria decision-making problems. Management Decision, 57 (9), 2501–2519. https://doi.org/10.1108/md-05-2017-0458

- Sensuse, D. I., Cahyaningsih, E., Wibowo, W. C. (2015). Identifying Knowledge Management Process of Indonesian Government Human Capital Management Using Analytical Hierarchy Process and Pearson Correlation Analysis. Procedia Computer Science, 72, 233–243. https://doi.org/10.1016/j.procs.2015.12.136

- Pan, N., Luo, Y. Y., Duan, Q. X. (2022). The Influence of PDCA Cycle Management Mode on the Enthusiasm, Efficiency, and Teamwork Ability of Nurses. BioMed Research International, 2022, 1–7. https://doi.org/10.1155/2022/9352735

- Prystynskyi, S. V. (2024). Tekhnolohiyi pererobky bahatokomponentnykh vidkhodiv polimernykh kompozytiv metodom lyttia pid tyskom. Kyiv, 160. Available at: https://knutd.edu.ua/files/science/razovi-vcheni-rady/Prystynskyi_disertation.pdf

- Haug, N., Geyrhofer, L., Londei, A., Dervic, E., Desvars-Larrive, A., Loreto, V. et al. (2020). Ranking the effectiveness of worldwide COVID-19 government interventions. Nature Human Behaviour, 4 (12), 1303–1312. https://doi.org/10.1038/s41562-020-01009-0

- Feng, Y., Ning, M., Lei, Y., Sun, Y., Liu, W., Wang, J. (2019). Defending blue sky in China: Effectiveness of the “Air Pollution Prevention and Control Action Plan” on air quality improvements from 2013 to 2017. Journal of Environmental Management, 252, 109603. https://doi.org/10.1016/j.jenvman.2019.109603

- Liu, S., Lucy Liu, X., Wang, H., Wang, Y. (2021). Humble Leader Behavior and Its Effects on Performance at the Team and Individual Level: A Multi-Perspective Study. Group & Organization Management, 47 (5), 1008–1041. https://doi.org/10.1177/10596011211024429

- Hamre, K. V., Fauske, M. R., Reknes, I., Nielsen, M. B., Gjerstad, J., Einarsen, S. V. (2021). Preventing and Neutralizing the Escalation of Workplace Bullying: the Role of Conflict Management Climate. International Journal of Bullying Prevention, 4 (4), 255–265. https://doi.org/10.1007/s42380-021-00100-y

- Liu, F., Chow, I. H.-S., Gong, Y., Huang, M. (2019). Affiliative and aggressive humor in leadership and their effects on employee voice: a serial mediation model. Review of Managerial Science, 14 (6), 1321–1339. https://doi.org/10.1007/s11846-019-00334-7

- Sarangee, K. R., Schmidt, J. B., Calantone, R. J. (2019). Anticipated regret and escalation of commitment to failing, new product development projects in business markets. Industrial Marketing Management, 76, 157–168. https://doi.org/10.1016/j.indmarman.2018.08.008

- Santos, R. C., Martinho, J. L. (2019). An Industry 4.0 maturity model proposal. Journal of Manufacturing Technology Management, 31 (5), 1023–1043. https://doi.org/10.1108/jmtm-09-2018-0284

- Gupta, K. (2022). A review on implementation of 5S for workplace management. Journal of Applied Research on Industrial Engineering, 9 (3), 323–330. https://doi.org/10.22105/jarie.2021.292741.1347

- Tiwari, K. V., Sharma, S. K. (2022). The Impact of Productivity Improvement Approach Using Lean Tools in an Automotive Industry. Process Integration and Optimization for Sustainability, 6 (4), 1117–1131. https://doi.org/10.1007/s41660-022-00252-4

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Serhii Prystynskyi, Olena Palyvoda, Viktoriia Plavan, Oleg Lozovyi, Andrii Hrytsenko

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.