Identifying the influence of the concentration of surfactants on the technological indicators of aerosol emulsion

DOI:

https://doi.org/10.15587/1729-4061.2024.317819Keywords:

emulsion system, Emulgin B2, Lanett SX, sodium laureth sulfate, moisturizing agents, propylene glycol, glyceryl cocoateAbstract

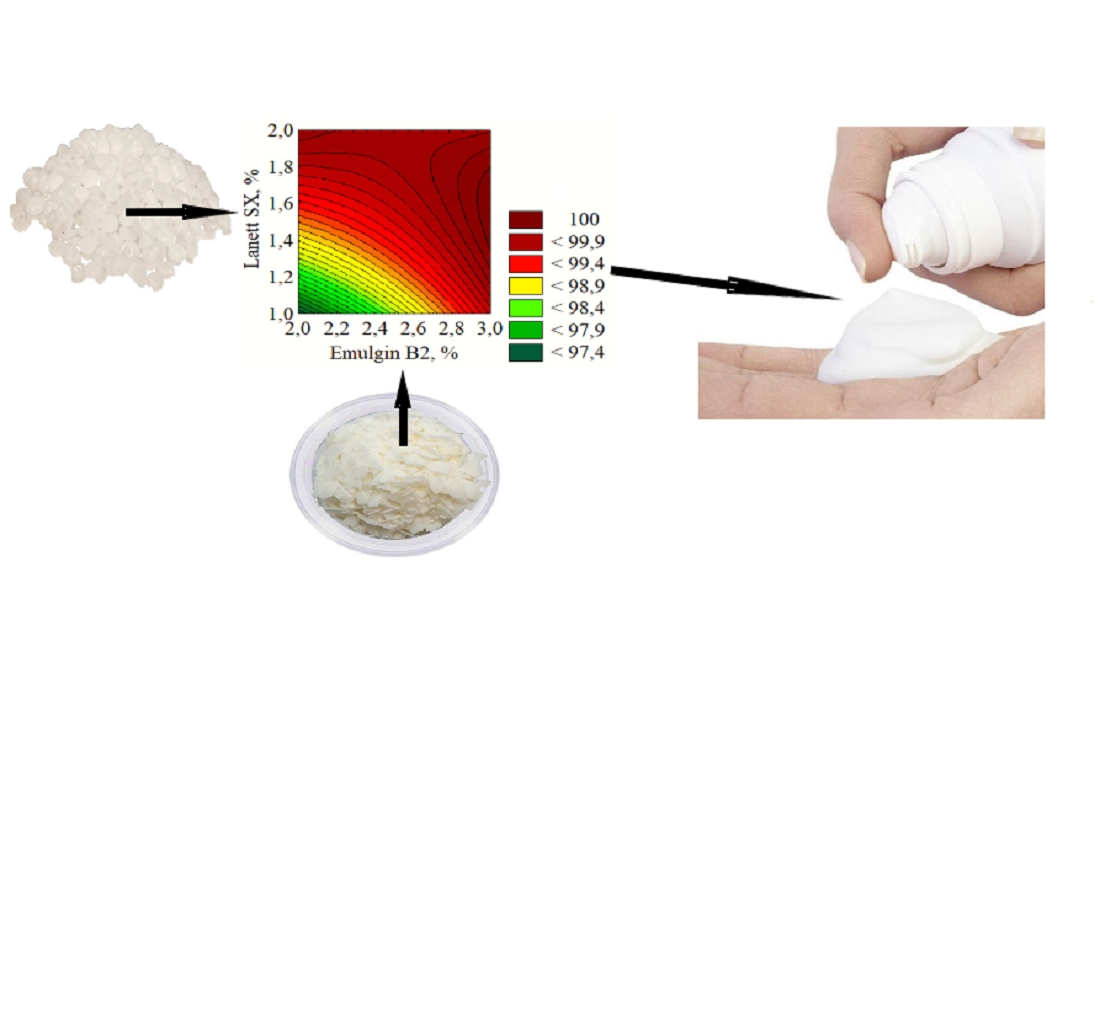

The object of the study is an emulsion system containing emulsifiers (Emulgin B2, Lanett SX), wetting agents (propylene glycol, glyceryl cocoate) and sodium laureth sulfate as a foaming agent. The main problem solved in the study is to ensure rational technological properties of emulsion systems in aerosol form under variable storage and use conditions. The results obtained showed that to ensure maximum emulsion stability during 7 and 30 days of storage, the optimal concentrations of Emulgin B2 are 2.75…3.0 %, and Lanett SX is 2.0…2.5 %. To achieve the desired foaming ability (80…85 %) and foam stability (75…80 %), it is recommended to use sodium laureth sulfate at a concentration of 0.20…0.22 %. It was found that the wetting agents – propylene glycol (7 %) and glyceryl cocoate (1.5 %) – provide optimal system viscosity within 35…40 mPa·s. The stability of the emulsion is ensured by the formation of strong interfacial films using Lanett SX, while Emulgin B2 improves the thermal stability of the system. Foaming properties are provided by the ability of sodium laureth sulfate to reduce interfacial tension, however, too high concentrations can lead to foam oversaturation and deterioration of its stability. The features of the obtained results are that specific concentration limits of the components are justified, at which the necessary stability and functionality of the emulsion system are ensured. This allows solving the problem of achieving optimal characteristics of the emulsion system during storage and use, ensuring comfortable application to the skin and a stable foam structure. The scope of application of the obtained results is the cosmetic industry

References

- Kovaliova, O., Pivovarov, O., Kalyna, V., Tchoursinov, Y., Kunitsia, E., Chernukha, A. et al. (2020). Implementation of the plasmochemical activation of technological solutions in the process of ecologization of malt production. Eastern-European Journal of Enterprise Technologies, 5 (10 (107)), 26–35. https://doi.org/10.15587/1729-4061.2020.215160

- Kovaliova, O., Tchoursinov, Y., Kalyna, V., Koshulko, V., Kunitsia, E., Chernukha, A. et al. (2020). Identification of patterns in the production of a biologically-active component for food products. Eastern-European Journal of Enterprise Technologies, 2 (11 (104)), 61–68. https://doi.org/10.15587/1729-4061.2020.200026

- Bliznjuk, O., Masalitina, N., Mezentseva, I., Novozhylova, T., Korchak, M., Haliasnyi, I. et al. (2022). Development of safe technology of obtaining fatty acid monoglycerides using a new catalyst. Eastern-European Journal of Enterprise Technologies, 2 (6 (116)), 13–18. https://doi.org/10.15587/1729-4061.2022.253655

- Ilyasoglu Buyukkestelli, H., El, S. N. (2019). Development and characterization of double emulsion to encapsulate iron. Journal of Food Engineering, 263, 446–453. https://doi.org/10.1016/j.jfoodeng.2019.07.026

- Varanasi, S., Henzel, L., Mendoza, L., Prathapan, R., Batchelor, W., Tabor, R., Garnier, G. (2018). Pickering Emulsions Electrostatically Stabilized by Cellulose Nanocrystals. Frontiers in Chemistry, 6. https://doi.org/10.3389/fchem.2018.00409

- Elaine, E., Bhandari, B., Tan, C. P., Nyam, K. L. (2024). Recent Advances in the Formation, Stability, and Emerging Food Application of Water-in-Oil-in-Water Double Emulsion Carriers. Food and Bioprocess Technology, 17 (11), 3440–3460. https://doi.org/10.1007/s11947-024-03350-y

- Bhattacharjee, A., Chakraborty, A., Mukhopadhyay, G. (2018). Double emulsions - A review with emphasis on updated stability enhancement perspective. World Journal of Pharmacy and Pharmaceutical Sciences, 7 (6), 475–493. Available at: https://www.researchgate.net/publication/325568289_DOUBLE_EMULSIONS_-_A_REVIEW_WITH_EMPHASIS_ON_UPDATED_STABILITY_ENHANCEMENT_PERSPECTIVE

- Sayyar, Z., Jafarizadeh-Malmiri, H. (2024). Enhancing the efficacy of nano-curcumin on cancer cells through mixture design optimization of three emulsifiers. BMC Chemistry, 18 (1). https://doi.org/10.1186/s13065-024-01160-z

- Zheng, Y., Zi, Y., Shi, C., Gong, H., Zhang, H., Wang, X., Zhong, J. (2023). Tween emulsifiers improved alginate-based dispersions and ionic crosslinked milli-sized capsules. Npj Science of Food, 7 (1). https://doi.org/10.1038/s41538-023-00208-z

- Blankart, M., Oellig, C., Averweg, S., Schwack, W., Hinrichs, J. (2020). Effect of storage at high temperature on chemical (composition) and techno-functional characteristics of E471 food emulsifiers applied to aerosol whipping cream. Journal of Food Engineering, 277, 109882. https://doi.org/10.1016/j.jfoodeng.2019.109882

- Schick, D., Link, K., Schwack, W., Granvogl, M., Oellig, C. (2021). Analysis of mono-, di-, triacylglycerols, and fatty acids in food emulsifiers by high-performance liquid chromatography–mass spectrometry. European Food Research and Technology, 247 (4), 1023–1034. https://doi.org/10.1007/s00217-021-03684-3

- Franzol, A., Banin, T. M., Brazil, T. R., Rezende, M. C. (2021). Assessment of kinetic stability of cosmetic emulsions formulated with different emulsifiers using rheological and sensory analyses. Journal of Sol-Gel Science and Technology, 99 (3), 469–481. https://doi.org/10.1007/s10971-021-05587-x

- Blankart, M., Kratzner, C., Link, K., Oellig, C., Schwack, W., Hinrichs, J. (2020). Technical emulsifiers in aerosol whipping cream – Compositional variations in the emulsifier affecting emulsion and foam properties. International Dairy Journal, 102, 104578. https://doi.org/10.1016/j.idairyj.2019.104578

- Felix-Sagaste, K. G., Garcia-Carrasco, M., Picos-Corrales, L. A., Gonzalez-Ruelas, T., Rodriguez-Mercado, J. A. (2023). Plant-animal extracts and biocompatible polymers forming oil-in-water emulsions: Formulations for food and pharmaceutical industries. Hybrid Advances, 3, 100072. https://doi.org/10.1016/j.hybadv.2023.100072

- Oellig, C., Blankart, M., Hinrichs, J., Schwack, W., Granvogl, M. (2020). Determination of mono- and diacylglycerols from E 471 food emulsifiers in aerosol whipping cream by high-performance thin-layer chromatography–fluorescence detection. Analytical and Bioanalytical Chemistry, 412 (27), 7441–7451. https://doi.org/10.1007/s00216-020-02876-2

- Raisel, L. B., Colet, R., Nascimento, L. H. do, Cardoso, L., Azambuja, L. L., Souza Zanchetta, B. de et al. 2024). Development of an innovative stabilizer-emulsifier mixture to enhance the quality of ice cream on a structured scale. Journal of Food Measurement and Characterization, 18 (7), 6250–6263. https://doi.org/10.1007/s11694-024-02644-1

- Petik, I., Belinska, A., Kunitsia, E., Bochkarev, S., Ovsiannikova, T., Kalyna, V. et al. (2021). Processing of ethanol-containing waste of oil neutralization in the technology of hand cleaning paste. Eastern-European Journal of Enterprise Technologies, 1 (10 (109)), 23–29. https://doi.org/10.15587/1729-4061.2021.225233

- Khosharay, S., Rahmanzadeh, M., ZareNezhad, B. (2020). Surface Behavior of Aqueous Solutions of Sodium Lauryl Ether Sulfate, Additives and Their Mixtures: Experimental and Modeling Study. International Journal of Thermophysics, 41 (12). https://doi.org/10.1007/s10765-020-02738-0

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Bogdan Putyatin, Olga Bliznjuk, Nataliia Masalitina, Valentyna Bezpal'ko, Liubov Zhukova, Olesia Filenko, Viktoriia Horiainova, Maryna Ponomarova, Anton Ryabev, Dmytro Beliuchenko

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.