Substantiating technological factors for preparing fermented milk-containing products with a combined composition of raw materials with a long storage period

DOI:

https://doi.org/10.15587/1729-4061.2024.317953Keywords:

fat mixtures, emulsion, microstructure, homogenization, thermomechanical processing, consistency, dynamic viscosityAbstract

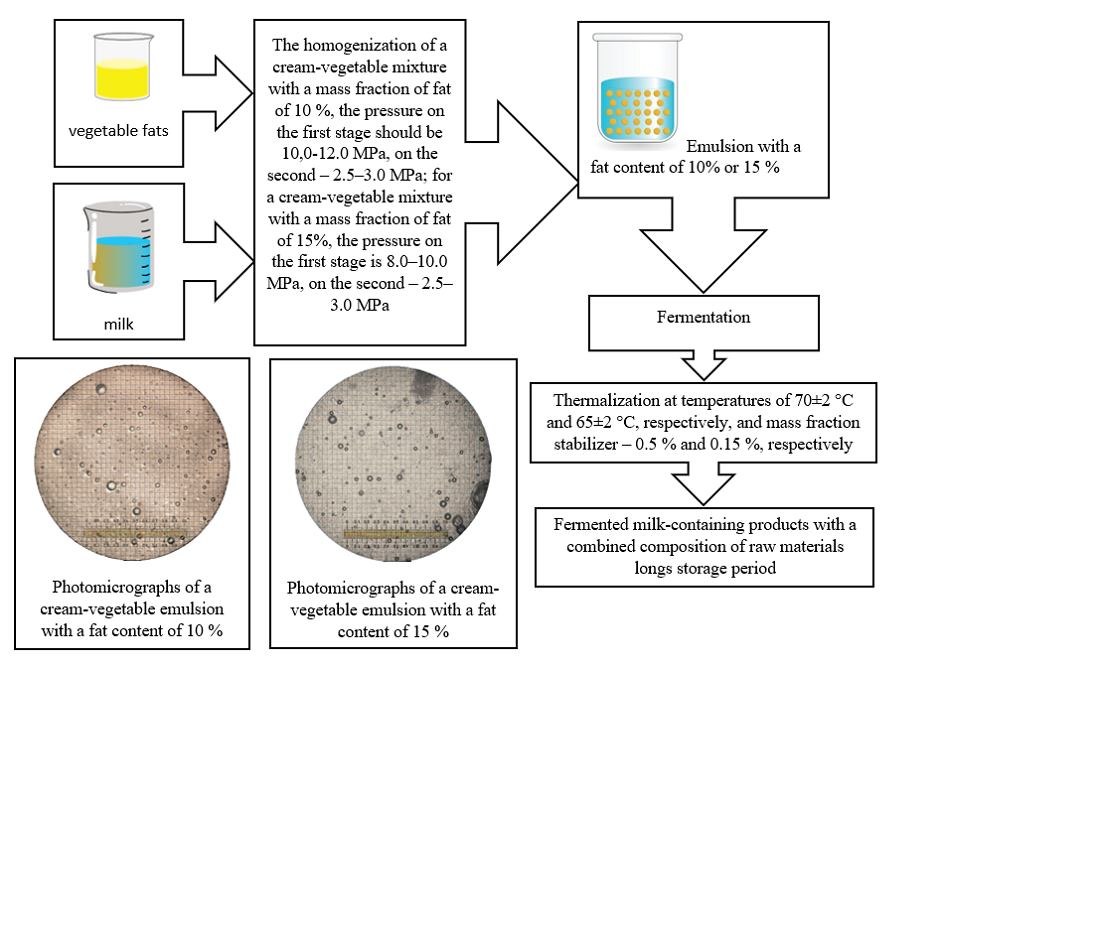

This paper substantiates and defines the technological parameters for obtaining stable emulsions when making fermented milk-containing products. The object of research was the modes of mechanical and heat treatment of mixtures with a combined composition of raw materials based on dairy and vegetable fats. The task to be solved was to obtain stable emulsions by two-stage homogenization of the cream-vegetable mixture and the heat treatment temperature of the fermented cream-vegetable mixture with a combined composition of raw materials with a fat content of 10 % and 15 %. It is shown that during the homogenization of a cream-vegetable mixture with a mass fraction of fat of 10 %, the pressure in the first stage should be 10.0–12.0 MPa, in the second – 2.5–3.0 MPa; for a cream-vegetable mixture with a mass fraction of fat of 15 %, the pressure in the first stage is 8.0–10.0 MPa, in the second – 2.5–3.0 MPa. Modes of thermomechanical processing of the fermented cream-vegetable mixture at temperatures of 65±2 and 70±2 °C to ensure the microbiological stability of the milk-containing product during storage have been substantiated. A stabilizing system based on milk proteins has been selected. It was established that in order to improve the consistency, increase heat resistance, and avoid foaming of the finished product, it is necessary to perform thermomechanical processing of the fermented cream-vegetable mixture with a fat content of 10 % and 15 % at temperatures of 70±2 °С and 65±2 °С, respectively, and mass fraction stabilizer – 0.5 % and 0.15 %, respectively. The research data do not always coincide with previously established patterns, which is due to the difference in the chemical composition of the studied food systems, as well as the methods of their preparation and use. The results of the work could be used in the technology of milk-containing products with a combined fat composition

References

- Kozak, O., Hryschenko, O. (2022). Dairy market: global development trends and Ukrainian prospects. Herald of Khmelnytskyi National University. Economic Sciences, 308 (4), 90–96. https://doi.org/10.31891/2307-5740-2022-308-4-14

- Cherevko, O. I., Peresichnyi, M. I., Peresichna, S. M. et al.; Cherevko, O. I., Peresichnyi, M. I. (Eds.) (2017). Innovatsiini tekhnolohiyi kharchovoi produktsiyi funktsionalnoho pryznachennia. Ch. 1. Kharkiv: KhDUKhT, 962.

- Ustymenko, I. M., Polishchuk, H. Ye. (2016). Rozroblennia novoho vydu kyslomolochnoho produktu kombinovanoho skladu. Kharchova promyslovist, 20, 93–99. Available at: http://nbuv.gov.ua/UJRN/Khp_2016_20_16

- Savchenko, O. A., Hrek, O. V., Krasulia, O. O. (2017). Tekhnolohiya vyrobnytstva molochnykh produktiv spetsialnoho pryznachennia. Kyiv: TsP Komprynt, 218.

- Belemets, T., Yushchenko, N., Lobok, A., Radzievskaya, I., Polonskaya, T. (2016). Optimization of composition of blend of natural vegetable oils for the production of milk-containing products. Eastern-European Journal of Enterprise Technologies, 5 (11 (83)), 4–9. https://doi.org/10.15587/1729-4061.2016.81405

- Ustymenko, І., Breus, N., Polischuk, G. (2016). Scientific basis for emulsion composition intended for normalization of milkcontaining products. Scientific Works of NUFT, 22 (5), 183–188. Available at: http://nbuv.gov.ua/UJRN/Npnukht_2016_22_5_24

- Kasprzak, M. M., Sady, M., Kruk, J., Bartkova, S., Sanka, I., Scheler, O. et al. (2023). Replacement of milk fat by rapeseed oil stabilised emulsion in commercial yogurt. PeerJ, 11, e16441. https://doi.org/10.7717/peerj.16441

- Unger, A. L., Torres-Gonzalez, M., Kraft, J. (2019). Dairy Fat Consumption and the Risk of Metabolic Syndrome: An Examination of the Saturated Fatty Acids in Dairy. Nutrients, 11 (9), 2200. https://doi.org/10.3390/nu11092200

- Comerford, K. B., Miller, G. D., Boileau, A. C., Masiello Schuette, S. N., Giddens, J. C., Brown, K. A. (2021). Global Review of Dairy Recommendations in Food-Based Dietary Guidelines. Frontiers in Nutrition, 8. https://doi.org/10.3389/fnut.2021.671999

- Astrup, A., Bertram, H. C., Bonjour, J.-P., de Groot, L. C., de Oliveira Otto, M. C. et al. (2019). WHO draft guidelines on dietary saturated and trans fatty acids: time for a new approach? BMJ, l4137. https://doi.org/10.1136/bmj.l4137

- Leong, T. S. H., Zhou, M., Zhou, D., Ashokkumar, M., Martin, G. J. O. (2018). The formation of double emulsions in skim milk using minimal food-grade emulsifiers – A comparison between ultrasonic and high pressure homogenisation efficiencies. Journal of Food Engineering, 219, 81–92. https://doi.org/10.1016/j.jfoodeng.2017.09.018

- Lalwani, S., Lewerentz, F., Håkansson, A., Löfgren, R., Eriksson, J., Paulsson, M., Glantz, M. (2024). Impact of thermal processing on micronutrients and physical stability of milk and cream at dairy production scale. International Dairy Journal, 153, 105901. https://doi.org/10.1016/j.idairyj.2024.105901

- Kashaninejad, M., Razavi, S. M. A. (2020). Influence of thermosonication treatment on the average size of fat globules, emulsion stability, rheological properties and color of camel milk cream. LWT, 132, 109852. https://doi.org/10.1016/j.lwt.2020.109852

- Kiełczewska, K., Ambroziak, K., Krzykowska, D., Aljewicz, M. (2021). The effect of high-pressure homogenisation on the size of milk fat globules and MFGM composition in sweet buttermilk and milk. International Dairy Journal, 113, 104898. https://doi.org/10.1016/j.idairyj.2020.104898

- Trujillo-Ramirez, D., Olivares-Martinez, I., Lobato-Calleros, C., Rodriguez-Huezo, E., Jaime Vernon-Carter, E., Alvarez-Ramirez, J. (2022). Impact of the droplet size of canola oil-in-water emulsions on the rheology and sensory acceptability of reduced-milk fat stirred yogurt. Journal of Food Science and Technology, 59 (12), 4853–4862. https://doi.org/10.1007/s13197-022-05573-3

- Ustymenko, І., Korh, N., Teterina, S., Polischuk, G. (2018). Analysis of microbiological indicators of food emulsions. Scientific Works of NUFT, 24 (2), 209–215. https://doi.org/10.24263/2225-2924-2018-24-2-25

- Andreus, S., Romanchuk, I. (2022). Optimization of the technological parameters for production of the fermented product with combined composition of raw materials. Food Resources, 10 (19), 18–25. https://doi.org/10.31073/foodresources2022-19-02

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Svitlana Andreus, Iryna Romanchuk, Tetіana Rudakova, Sergiy Narizhnyy

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.