Identifying the influence of various technological techniques on the indicators of the composition of bunches and wine samples of the madras grape variety

DOI:

https://doi.org/10.15587/1729-4061.2024.318532Keywords:

autochthonous, antioxidant activity, cluster, monomeric anthocyanins, residue, maceration, skin, pipsAbstract

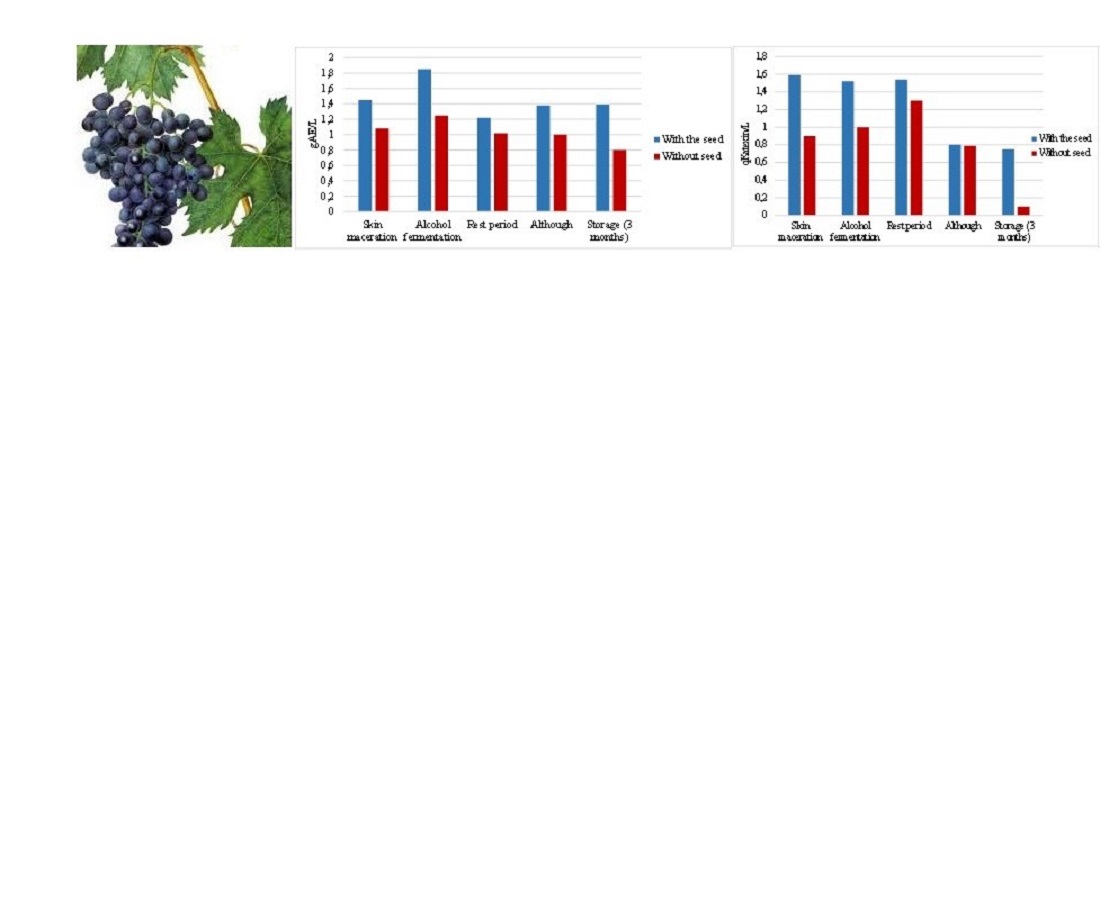

The object of research is wine samples obtained by maceration of seeded and seedless skins from the autochthonous Madrasa grape variety. The studies were conducted on the autochthonous Madrasa grape variety the influence of the mechanical composition of the bunch and the applied technological methods on the wine composition and quality indicators of wine was not been studied. For the four variants with different numbers of bunches stored in the tin, the amount of lactic juice in % was 83.85–86.03 %, the structural index was 5.2–6.2, and no big difference was noticed between the variants. The amount of phenolic compounds was higher in the fermentation of the pulp with the seed than without the seed. The amount of phenolic compounds was highest (1.87 gAE/L) during alcohol fermentation, and lowest (1.22 gAE/L) during the rest period. The amount of anthocyanins in peel maceration with seeds was 0.118 gMvd-3-0-glu/u, this amount was 0.137 gMvd-3-0-glu/u in fermentation without seeds. After alcohol fermentation, those indicators were 0.140 and 0.208 gMvd-3-0-glu/u, reaching the maximum, respectively. The samples obtained from the Madrasa grape variety, macerated for 48 and 96 hours, were divided into two parts, one of which was fermented with natural yeasts (TQ) and the other with cultured yeasts (MMQ). The amount of total phenolic compounds and phenolic acids in TQ was lower than that of MMQ samples, and the amount of aromatic compounds, on the contrary, was higher in naturally fermented than in samples fermented with cultured yeasts. These studies are important for production in terms of regulating the number of clusters stored in the barrel and the processes occurring during the stages of wine production. The obtained results can be used in family farms and wineries

References

- Delić, M., Behmen, F., Sefo, S., Drkenda, P., Matijašević, S., Mandić, A. (2023). Effect of Pruning on Mechanical Composition of Bunch of Table Grape Varieties (Vitis Vinifera L.). 32nd Scientific-Expert Conference of Agriculture and Food Industry, 72–81. https://doi.org/10.1007/978-3-031-47467-5_8

- Wang, H., Liao, X., Lin, C., Bai, W., Xiao, G., Huang, X., Liu, G. (2024). Optimization of fermentation conditions, physicochemical profile and sensory quality analysis of seedless wampee wine. Applied Biological Chemistry, 67 (1). https://doi.org/10.1186/s13765-024-00938-y

- Liang, H., Gao, D., Wang, C., Gao, H., Guo, Y., Zhao, Z., Shi, H. (2022). Effect of Fermentation Strategy on the Quality and Aroma Characteristics of Yellow Peach Wines. Fermentation, 8 (11), 604. https://doi.org/10.3390/fermentation8110604

- Massera, A., Assof, M., Sari, S., Ciklic, I., Mercado, L., Jofré, V., Combina, M. (2021). Effect of low temperature fermentation on the yeast-derived volatile aroma composition and sensory profile in Merlot wines. LWT, 142, 111069. https://doi.org/10.1016/j.lwt.2021.111069

- Guerrini, S., Galli, V., Mangani, S., Granchi, L. (2024). Influence of Cryoextraction and Cold Pre-Fermentative Maceration on the Yeast Microbiota and the Volatile Compounds Profile of Sangiovese Wine. Fermentation, 10 (3), 148. https://doi.org/10.3390/fermentation10030148

- Muñoz García, R., Oliver-Simancas, R., Arévalo Villena, M., Martínez-Lapuente, L., Ayestarán, B., Marchante-Cuevas, L. et al. (2022). Use of Microwave Maceration in Red Winemaking: Effect on Fermentation and Chemical Composition of Red Wines. Molecules, 27 (9), 3018. https://doi.org/10.3390/molecules27093018

- Gutiérrez, A. R., Santamaría, P., González-Arenzana, L., Garijo, P., Olarte, C., Sanz, S. (2023). Yeasts Inoculation Effect on Bacterial Development in Carbonic Maceration Wines Elaboration. Foods, 12 (14), 2755. https://doi.org/10.3390/foods12142755

- Malićanin, M., Danilović, B., Stamenković Stojanović, S., Cvetković, D., Lazić, M., Karabegović, I., Savić, D. (2022). Pre-Fermentative Cold Maceration and Native Non-Saccharomyces Yeasts as a Tool to Enhance Aroma and Sensory Attributes of Chardonnay Wine. Horticulturae, 8 (3), 212. https://doi.org/10.3390/horticulturae8030212

- Jardim, G. V., Zigiotto, L., Machado, W., Marcon, Â. R. (2019). Effects of sulfur dioxide on wine made with sulfitic maceration. BIO Web of Conferences, 12, 02003. https://doi.org/10.1051/bioconf/20191202003

- Zhang, Y.-S., Du, G., Gao, Y.-T., Wang, L.-W., Meng, D., Li, B.-J. et al. (2019). The Effect of Carbonic Maceration during Winemaking on the Color, Aroma and Sensory Properties of ‘Muscat Hamburg’ Wine. Molecules, 24 (17), 3120. https://doi.org/10.3390/molecules24173120

- Fataliyev, H., Malikov, A., Lezgiyev, Y., Gadimova, N., Musayev, T., Aliyeva, G. (2024). Identifying of the wine-making potential of the autochthon madrasa grape variety of different colors and quality. Eastern-European Journal of Enterprise Technologies, 2 (11 (128)), 56–63. https://doi.org/10.15587/1729-4061.2024.302971

- Fataliyev, H., Malikov, A., Lazgiyev, Y., Haydarov, E., Agayeva, S., Baloghlanova, K. et al. (2023). Effect of maceration regime on phenolic compound quantity and color quality of madrasa wine samples. Food Science and Technology, 17 (4). https://doi.org/10.15673/fst.v17i4.2784

- Fataliyev, H. K. (2013). Winemaking practicum. Baku: Elm, 328.

- Sheskin, D. J. (2020). Handbook of Parametric and Nonparametric Statistical Procedures. Chapman and Hall/CRC, 1928. https://doi.org/10.1201/9780429186196

- Gadimova, N., Fataliyev, H., Heydarov, E., Lezgiyev, Y., Isgandarova, S. (2023). Development of a model and optimization of the interaction of factors in the grain malting process and its application in the production of functional beverages. Eastern-European Journal of Enterprise Technologies, 5 (11 (125)), 43–56. https://doi.org/10.15587/1729-4061.2023.289421

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Hasil Fataliyev, Yusif Lezgiyev, Yahya Aghazade, Natavan Gadimova, Elnur Heydarov, Mehman Ismailov

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.