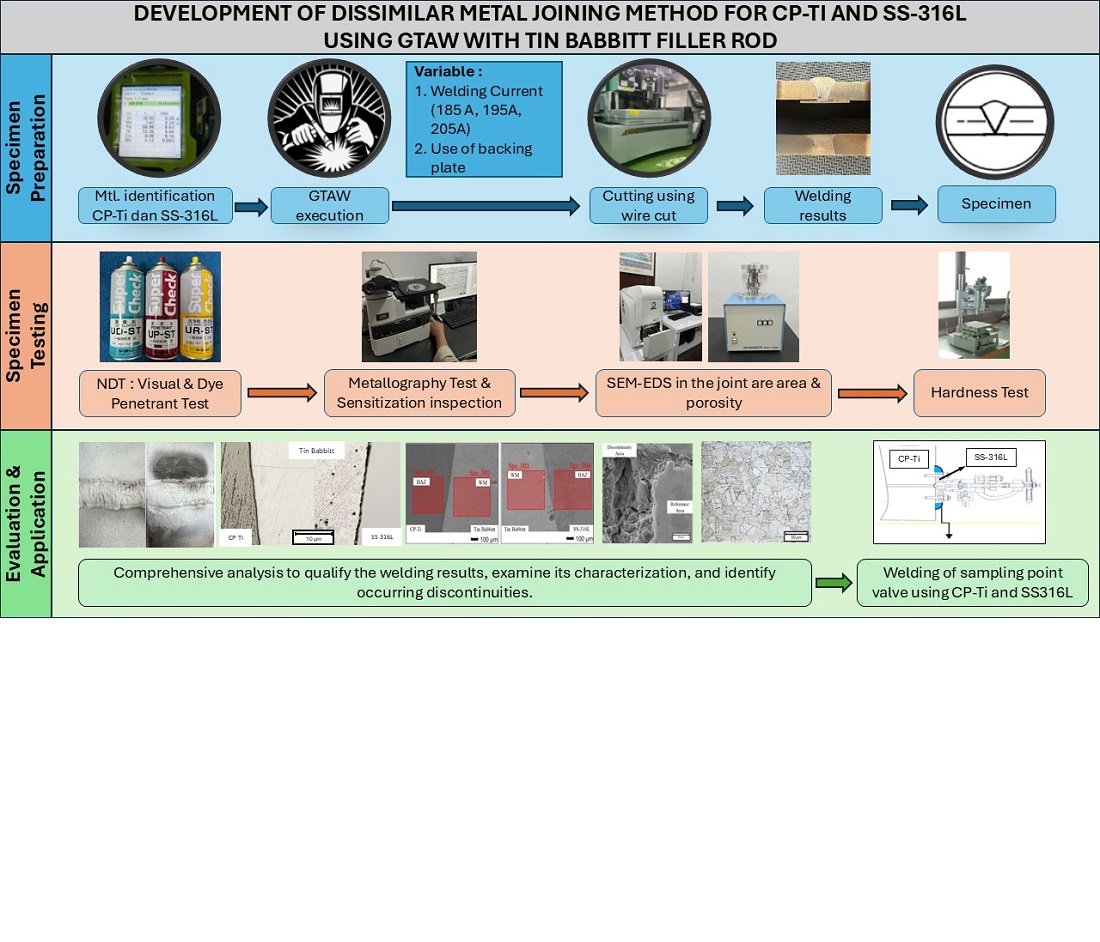

Development of dissimilar metal joining method for CP-Ti and SS-316L using gtaw with tin babbitt filler rod

DOI:

https://doi.org/10.15587/1729-4061.2025.320930Keywords:

dissimilar metal joining, CP-Ti, SS-316L, Tin Babbitt, GTAWAbstract

Dissimilar metal joining between commercial pure titanium (CP-Ti) and stainless steel 316L (SS-316L) poses challenges due to thermal property differences and brittle intermetallic compound formation. This study examines weldability and joint characteristics under varying welding currents (185A, 195A, 205A) and backing plate conditions. The main challenge is ensuring weld integrity while minimizing intermetallic compounds and defects that degrade mechanical properties. Non-destructive testing, metallography, SEM-EDS, and hardness testing were conducted. Results indicate that without a backing plate, hardness in the heat-affected zone (HAZ) of SS-316L increased with welding current, from 160.7 HV at 185 A to 167.5 HV at 205 A. In CP-Ti, hardness rose from 148 HV at 185 A to 160.7 HV at 205 A. With a backing plate, SS-316L HAZ hardness peaked at 185 A (182.7 HV) but decreased to 167.5 HV at 205 A. Similarly, CP-Ti hardness was lower with a backing plate (154 HV at 205 A BP). Sensitization in SS-316L was detected but remained mild. The tin babbitt filler rod suppressed brittle Fe-Ti intermetallic compounds due to its high thermal conductivity and low melting point, ensuring better heat distribution. This reduced cracking risks at the fusion line and improved bonding. However, porosity remained an issue, particularly in SS-316L joints, increasing at higher currents and potentially leading to microcracks. Controlling welding parameters and shielding conditions was crucial to minimizing porosity and enhancing joint quality. These findings confirm that optimizing welding parameters and environmental control reduces intermetallic compounds and porosity, improving GTAW feasibility for on-field welding in applications such as heat exchangers, piping, and pressure vessels

References

- Acar, M. T., Kovacı, H., Çelik, A. (2022). Comparison of the structural properties, surface wettability and corrosion resistance of TiO2 nanotubes fabricated on Cp-Ti, Ti6Al4V and Ti45Nb. Materials Today Communications, 33, 104396. https://doi.org/10.1016/j.mtcomm.2022.104396

- Chen, T., Lu, H. Z., Lin, J. A., Cai, W. S., Zhu, D. Z., Yang, C. (2023). Tailoring microstructure and mechanical properties of CP-Ti through combined treatment of pressure and pulsed electric current. Journal of Materials Research and Technology, 25, 3496–3506. https://doi.org/10.1016/j.jmrt.2023.06.147

- Li, B., Wang, X., Min, Y., Liang, C., Li, H., Guo, L. et al. (2016). Corrosion resistance and mechanical properties of titanium with hierarchical micro-nanostructure. Materials Letters, 182, 43–46. https://doi.org/10.1016/j.matlet.2016.06.079

- Chao, Q., Thomas, S., Birbilis, N., Cizek, P., Hodgson, P. D., Fabijanic, D. (2021). The effect of post-processing heat treatment on the microstructure, residual stress and mechanical properties of selective laser melted 316L stainless steel. Materials Science and Engineering: A, 821, 141611. https://doi.org/10.1016/j.msea.2021.141611

- Kong, D., Dong, C., Ni, X., Zhang, L., Yao, J., Man, C. et al. (2019). Mechanical properties and corrosion behavior of selective laser melted 316L stainless steel after different heat treatment processes. Journal of Materials Science & Technology, 35 (7), 1499–1507. https://doi.org/10.1016/j.jmst.2019.03.003

- Gao, Y., Tsumura, T., Nakata, K. (2012). Dissimilar welding of Titanium Alloys to Steels. Transactions of JWRI, 41 (2). Available at: http://nakata-wjs.info/assets/pdf/jwri/078.pdf

- Tomashchuk, I., Sallamand, P., Belyavina, N., Pilloz, M. (2013). Evolution of microstructures and mechanical properties during dissimilar electron beam welding of titanium alloy to stainless steel via copper interlayer. Materials Science and Engineering: A, 585, 114–122. https://doi.org/10.1016/j.msea.2013.07.050

- Mannucci, A., Tomashchuk, I., Mathieu, A., Cicala, E., Boucheron, T., Bolot, R., Lafaye, S. (2018). Direct laser welding of pure titanium to austenitic stainless steel. Procedia CIRP, 74, 485–490. https://doi.org/10.1016/j.procir.2018.08.138

- Shanmugarajan, B., Padmanabham, G. (2012). Fusion welding studies using laser on Ti–SS dissimilar combination. Optics and Lasers in Engineering, 50 (11), 1621–1627. https://doi.org/10.1016/j.optlaseng.2012.05.008

- Ranjan Giri, S., Kumar Khamari, B., Ranjan Moharana, B. (2022). Joining of titanium and stainless steel by using different welding processes: A review. Materials Today: Proceedings, 66, 505–508. https://doi.org/10.1016/j.matpr.2022.05.590

- Yu, D., Zhang, Y., Hosseini, S. R. E., Zhou, J., Sun, D. (2023). Element diffusion and microstructure evolution at interface of stainless steel/Ti alloy joint by laser welding with AgCuTi filler metal. Journal of Materials Research and Technology, 24, 6463–6472. https://doi.org/10.1016/j.jmrt.2023.04.217

- Balasubramanian, M., Murali, S., Hemadri, C., Kumar, R. (2021). A new method of dissimilar friction welding of titanium to stainless steel. Materials Today: Proceedings, 46, 3644–3647. https://doi.org/10.1016/j.matpr.2021.01.675

- Hao, X., Dong, H., Yu, F., Li, P., Yang, Z. (2021). Arc welding of titanium alloy to stainless steel with Cu foil as interlayer and Ni-based alloy as filler metal. Journal of Materials Research and Technology, 13, 48–60. https://doi.org/10.1016/j.jmrt.2021.04.054

- Gupta, S. K., Patil, A. P., Rathod, R. C., Tandon, V., Gupta, A. (2023). Characterization of microstructure, mechanical and corrosion response in AISI 304L and Ti-stabilized 439 stainless steels weld joints. Journal of Manufacturing Processes, 101, 721–736. https://doi.org/10.1016/j.jmapro.2023.05.107

- Moazami Goudarzi, M., Jenabali Jahromi, S. A., Nazarboland, A. (2009). Investigation of characteristics of tin-based white metals as a bearing material. Materials & Design, 30 (6), 2283–2288. https://doi.org/10.1016/j.matdes.2008.07.056

- Alcover Junior, P. R. C., Pukasiewicz, A. G. M. (2019). Evaluation of microstructure, mechanical and tribological properties of a Babbitt alloy deposited by arc and flame spray processes. Tribology International, 131, 148–157. https://doi.org/10.1016/j.triboint.2018.10.027

- He, X., Li, G., Song, S., Hua, J. (2025). Effect of deposition current on microstructure and tribological properties of tin-based Babbitt alloy on magnesium alloy deposited by TIG process. Surface and Coatings Technology, 496, 131702. https://doi.org/10.1016/j.surfcoat.2024.131702

- Li, J., Schneiderman, B., Gilbert, S. M., Vivek, A., Yu, Z., Daehn, G. (2020). Process characteristics and interfacial microstructure in spot impact welding of titanium to stainless steel. Journal of Manufacturing Processes, 50, 421–429. https://doi.org/10.1016/j.jmapro.2019.12.036

- Chattopadhyay, A., Muvvala, G., Sarkar, S., Racherla, V., Nath, A. K. (2022). Mitigation of cracks in laser welding of titanium and stainless steel by in-situ nickel interlayer deposition. Journal of Materials Processing Technology, 300, 117403. https://doi.org/10.1016/j.jmatprotec.2021.117403

- Zhang, R., Buchanan, C., Matilainen, V.-P., Daskalaki-Mountanou, D., Britton, T. B., Piili, H. et al. (2021). Mechanical properties and microstructure of additively manufactured stainless steel with laser welded joints. Materials & Design, 208, 109921. https://doi.org/10.1016/j.matdes.2021.109921

- Taufiqurrahman, I., Lenggo Ginta, T., Mustapha, M. (2021). The effect of holding time on dissimilar resistance spot welding of stainless steel 316L and Ti6Al4V titanium alloy with aluminum interlayer. Materials Today: Proceedings, 46, 1563–1568. https://doi.org/10.1016/j.matpr.2020.07.237

- Bi, Y., Zhang, Y., Liu, K., Xu, Y., Xue, R. (2020). Two pass laser welding of 304 stainless to TC4 titanium alloy using monel 400/Nb bilayer. Journal of Materials Research and Technology, 9 (6), 16522–16528. https://doi.org/10.1016/j.jmrt.2020.11.060

- Jin, P., Sun, Q., Liu, Y., Li, J., Li, F., Liu, Y., Hou, S. (2020). Microstructural evolution and mechanical property of TC4/304 stainless steel joined by CMT using a CuSi3 filler wire. Journal of Manufacturing Processes, 60, 308–317. https://doi.org/10.1016/j.jmapro.2020.10.072

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Binar Ade Anugra, Raden Dadan Ramdan, Wahyudiono Wahyudiono

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.