Development of in-pipe defects detection and classification system

DOI:

https://doi.org/10.15587/1729-4061.2025.323293Keywords:

in-pipe defect, detection, classification, artificial intelligence algorithms, pattern recognitionAbstract

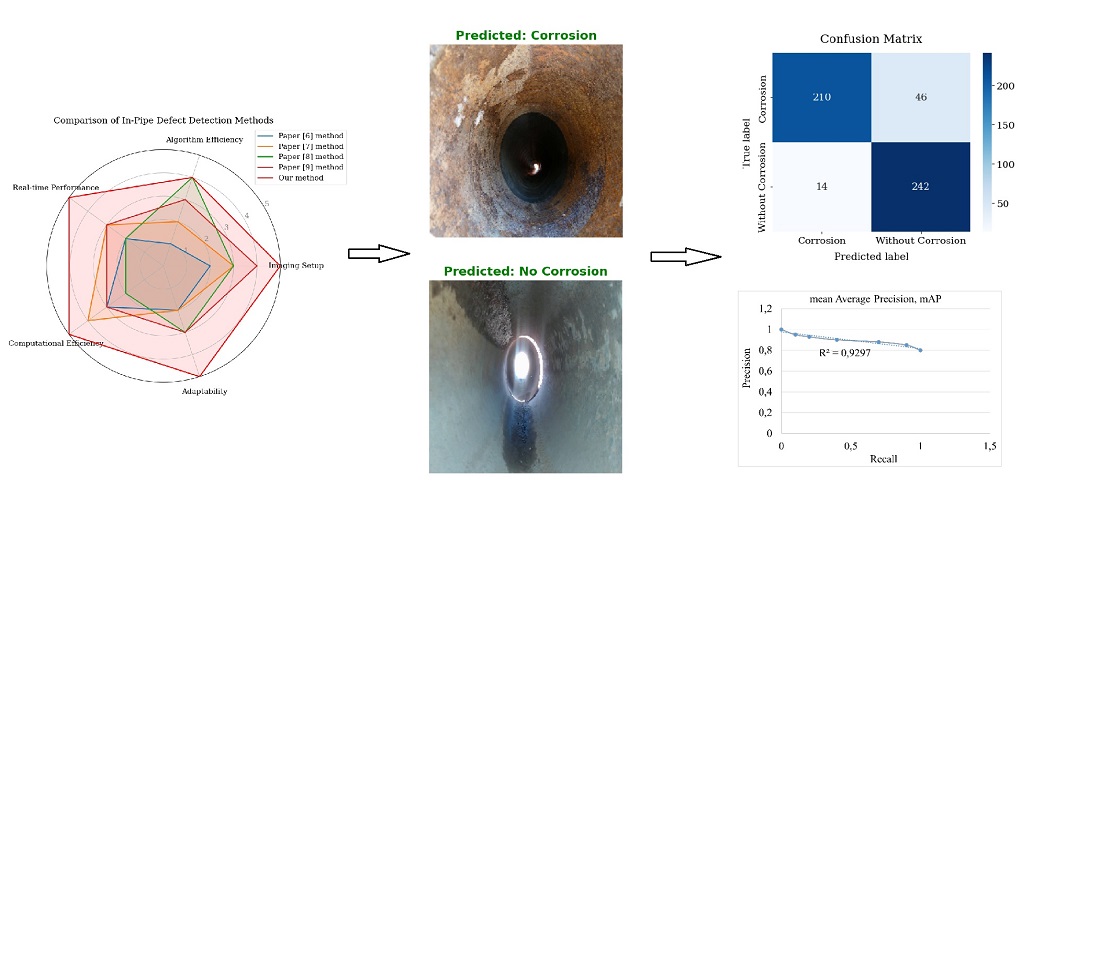

The object of the research is in-pipe defect detection and classification. The primary problem to be solved is the inefficiency, high cost, and inaccuracy of traditional manual inspection methods, which are often time-consuming and prone to human error. The results obtained include the creation of a multi-modal platform that integrates Red-Green-Blue (RGB) imaging and depth data with advanced artificial intelligence algorithms, Canny edge detection, and Density-Based Spatial Clustering of Applications with Noise (DBSCAN) clustering, achieving a 93 % mean Average Precision (mAP) in detecting and classifying various defects such as cracks, corrosion, and debris. A brief interpretation of the findings reveals that the high performance is due to the synergy between multi-modal sensing, artificial intelligence pattern recognition, and robust robotic navigation. This integrated approach ensures that the system not only detects defects accurately but does so in real time. Features and characteristics of the obtained results that directly address the identified problem include real-time high-precision defect identification, and reduced inspection downtime. As a result, inspection time is shortened, costs are lowered, and the safety of the pipeline system is increased, leading to accurate measurement of indicators (93 % mAP) and a reduction in occupational safety risks. The developed system is designed for use in traditional industrial environments, especially in large pipeline networks and in conditions where traditional methods are ineffective

References

- Wang, W., Mao, X., Liang, H., Yang, D., Zhang, J., Liu, S. (2021). Experimental research on in-pipe leaks detection of acoustic signature in gas pipelines based on the artificial neural network. Measurement, 183, 109875. https://doi.org/10.1016/j.measurement.2021.109875

- Wong, B., McCann, J. A. (2021). Failure Detection Methods for Pipeline Networks: From Acoustic Sensing to Cyber-Physical Systems. Sensors, 21 (15), 4959. https://doi.org/10.3390/s21154959

- Barile, C., Casavola, C., Pappalettera, G., Kannan, V. P., Mpoyi, D. K. (2022). Acoustic Emission and Deep Learning for the Classification of the Mechanical Behavior of AlSi10Mg AM-SLM Specimens. Applied Sciences, 13 (1), 189. https://doi.org/10.3390/app13010189

- Altay, Y. A., Kuzivanov, D. O., Altay, D. A., Fedorov, A. V. (2024). Signal Processing for Acoustic Emission Signature Analysis and Defect Detection. 2024 26th International Conference on Digital Signal Processing and Its Applications (DSPA), 1–6. https://doi.org/10.1109/dspa60853.2024.10510110

- Wang, C., Tan, X. P., Tor, S. B., Lim, C. S. (2020). Machine learning in additive manufacturing: State-of-the-art and perspectives. Additive Manufacturing, 36, 101538. https://doi.org/10.1016/j.addma.2020.101538

- Sinha, S. K., Fieguth, P. W., Polak, M. A. (2003). Computer Vision Techniques for Automatic Structural Assessment of Underground Pipes. Computer-Aided Civil and Infrastructure Engineering, 18 (2), 95–112. https://doi.org/10.1111/1467-8667.00302

- Kim, H., Lee, B., Kim, R. (2006). Development of Computer-vision-based Pipe Inspection System. 2006 International Forum on Strategic Technology, 403–406. https://doi.org/10.1109/ifost.2006.312344

- Wang, M., Cheng, J. C. P. (2018). Development and Improvement of Deep Learning Based Automated Defect Detection for Sewer Pipe Inspection Using Faster R-CNN. Advanced Computing Strategies for Engineering, 171–192. https://doi.org/10.1007/978-3-319-91638-5_9

- Rayhana, R., Jiao, Y., Zaji, A., Liu, Z. (2021). Automated Vision Systems for Condition Assessment of Sewer and Water Pipelines. IEEE Transactions on Automation Science and Engineering, 18 (4), 1861–1878. https://doi.org/10.1109/tase.2020.3022402

- Moradi, S., Zayed, T., Golkhoo, F. (2019). Review on Computer Aided Sewer Pipeline Defect Detection and Condition Assessment. Infrastructures, 4 (1), 10. https://doi.org/10.3390/infrastructures4010010

- Oluwatosin, O. P., Syed, S. A., Apis, O., Kolawole, S. (2021). Application of Computer Vision in Pipeline Inspection Robot. Proceedings of the International Conference on Industrial Engineering and Operations Management. https://doi.org/10.46254/an11.20210374

- Colvalkar, A., Pawar, S. S., Patle, B. K. (2023). In-pipe inspection robotic system for defect detection and identification using image processing. Materials Today: Proceedings, 72, 1735–1742. https://doi.org/10.1016/j.matpr.2022.09.476

- Zholtayev, D., Dauletiya, D., Tileukulova, A., Akimbay, D., Nursultan, M., Bushanov, Y. et al. (2024). Smart Pipe Inspection Robot With In-Chassis Motor Actuation Design and Integrated AI-Powered Defect Detection System. IEEE Access, 12, 119520–119534. https://doi.org/10.1109/access.2024.3450502

- Haurum, J. B., Moeslund, T. B. (2021). Sewer-ML: A Multi-Label Sewer Defect Classification Dataset and Benchmark. 2021 IEEE/CVF Conference on Computer Vision and Pattern Recognition (CVPR), 13451–13462. https://doi.org/10.1109/cvpr46437.2021.01325

- Ru, G., Gao, B., Tang, Q., Jiang, S., Zhang, Y., Luo, F., Woo, W. L. (2023). Electromagnetic Coupling Sensing of Pipe In-Line Inspection System. IEEE Transactions on Instrumentation and Measurement, 72, 1–15. https://doi.org/10.1109/tim.2023.3310083

- Lyu, F., Zhou, X., Ding, Z., Qiao, X., Song, D. (2024). Application Research of Ultrasonic-Guided Wave Technology in Pipeline Corrosion Defect Detection: A Review. Coatings, 14 (3), 358. https://doi.org/10.3390/coatings14030358

- Niu, Y., Sun, L., Wang, Y., Shen, G., Shi, Y. (2024). New technology for pipeline defect detection. Science China Technological Sciences, 67 (4), 1294–1296. https://doi.org/10.1007/s11431-023-2473-x

- Mustafaev, B., Kim, S., Kim, E. (2023). Enhancing Metal Surface Defect Recognition Through Image Patching and Synthetic Defect Generation. IEEE Access, 11, 113339–113359. https://doi.org/10.1109/access.2023.3322734

- Li, Y., Wang, H., Dang, L. M., Song, H.-K., Moon, H. (2022). Vision-Based Defect Inspection and Condition Assessment for Sewer Pipes: A Comprehensive Survey. Sensors, 22 (7), 2722. https://doi.org/10.3390/s22072722

- Kenzhekhan, A., Bakytzhanova, A., Omirbayev, S., Tuieubayev, Y., Daniyalov, M., Yeshmukhametov, A. (2023). Design and Development of an In-Pipe Mobile Robot for Pipeline Inspection with AI Defect Detection System. 2023 23rd International Conference on Control, Automation and Systems (ICCAS), 579–584. https://doi.org/10.23919/iccas59377.2023.10316817

- Araújo, J. F., Ramos, V. M., Silva, C. A., Silva, H. D. (2024). Development of a Virtual Environment to Assist in the Identification and Analysis of Defects in Industrial Control Panels. IEEE Revista Iberoamericana de Tecnologias Del Aprendizaje, 19, 258–266. https://doi.org/10.1109/rita.2024.3475883

- Wang, X., Yang, L., Sun, T., Rasool, G., Sun, M., Hu, N., Guo, Z. (2023). A review of development and application of out-of-pipe detection technology without removing cladding. Measurement, 219, 113249. https://doi.org/10.1016/j.measurement.2023.113249

- Zhang, M., Guo, Y., Xie, Q., Zhang, Y., Wang, D., Chen, J. (2022). Defect identification for oil and gas pipeline safety based on autonomous deep learning network. Computer Communications, 195, 14–26. https://doi.org/10.1016/j.comcom.2022.08.001

- Changwang, S., Shaowei, H., Haifen, Z., Fuqu, P., Changxi, S., Hao, Q. (2024). Automatic Detection of Water Supply Pipe Defects Based on Underwater Image Enhancement and Improved YOLOX. Journal of Construction Engineering and Management, 150 (10). https://doi.org/10.1061/jcemd4.coeng-14919

- Fioravanti, C. C. B., Centeno, T. M., De Biase Da Silva Delgado, M. R. (2019). A Deep Artificial Immune System to Detect Weld Defects in DWDI Radiographic Images of Petroleum Pipes. IEEE Access, 7, 180947–180964. https://doi.org/10.1109/access.2019.2959810

- Lin, W., Li, P., Xie, X. (2022). A Novel Detection and Assessment Method for Operational Defects of Pipe Jacking Tunnel Based on 3D Longitudinal Deformation Curve: A Case Study. Sensors, 22 (19), 7648. https://doi.org/10.3390/s22197648

- Jeon, K.-W., Jung, E.-J., Bae, J.-H., Park, S.-H., Kim, J.-J., Chung, G. et al. (2024). Development of an In-Pipe Inspection Robot for Large-Diameter Water Pipes. Sensors, 24 (11), 3470. https://doi.org/10.3390/s24113470

- Luo, D., Du, K., Niu, D. (2024). Intelligent Diagnosis of Urban Underground Drainage Network: From Detection to Evaluation. Structural Control and Health Monitoring, 2024 (1). https://doi.org/10.1155/2024/9217395

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Perizat Rakhmetova, Gani Sergazin, Yeldos Altay, Daniyar Dauletiya, Lazzat Kurmangaliyeva

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.