Identifying the effect of refrigerant liquid level in receiver on energy efficiency and cooling performance of domestic freezers

DOI:

https://doi.org/10.15587/1729-4061.2025.326761Keywords:

refrigerant charge optimization, liquid receiver dynamics, subcooling efficiency, domestic freezer performance, R404A system behaviorAbstract

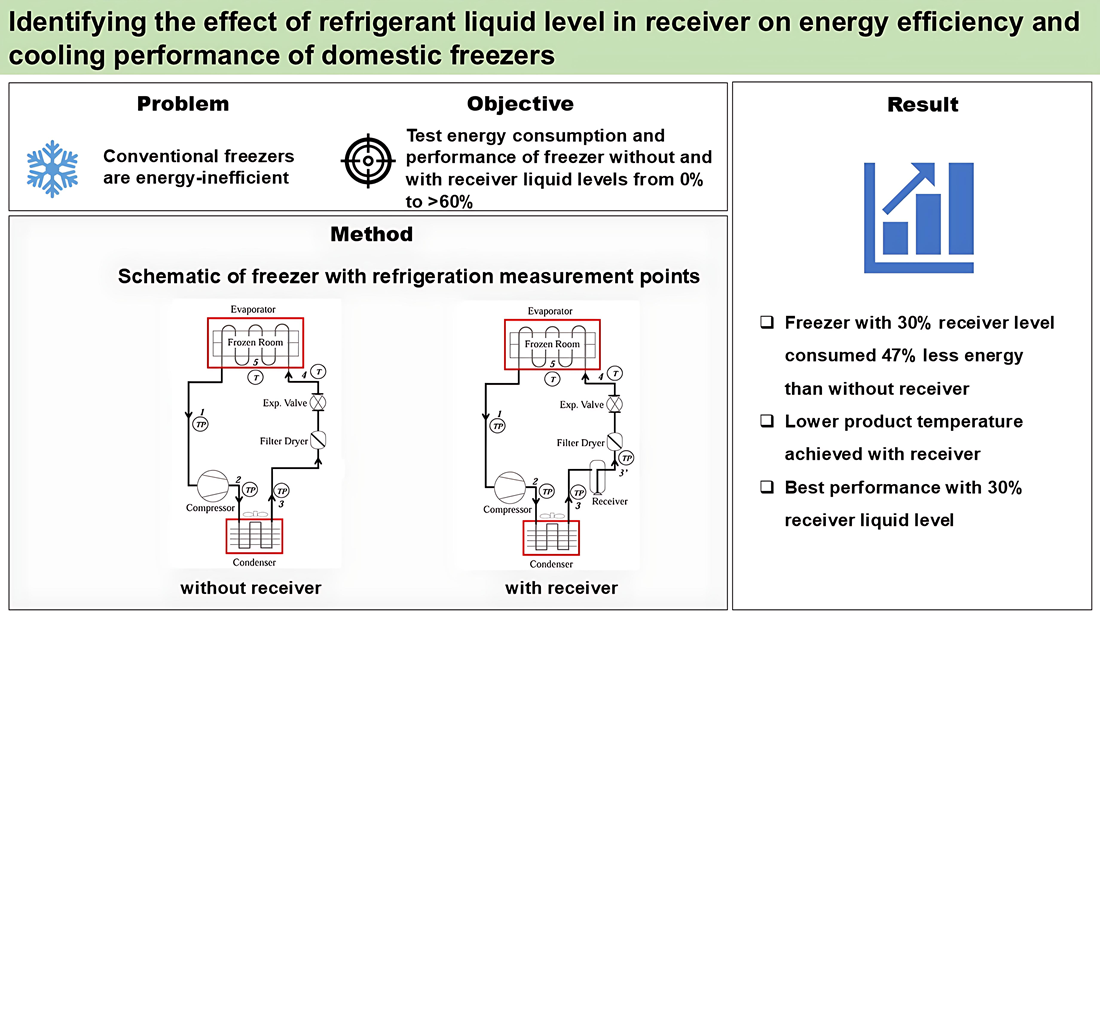

This study investigates a domestic vapor-compression freezer system utilizing R404A refrigerant and a 0.75 kW-rated compressor, with a focus on the impact of different liquid refrigerant levels in the receiver on system performance and energy consumption. One major issue in household freezers is excessive energy use, particularly in systems lacking fluid regulation mechanisms such as a receiver. To explore this, an experimental setup was developed to test six operating conditions: one without a receiver and five with varying refrigerant fill levels in the receiver, ranging from less than 0% to over 60%. Experimental results showed that the freezer without a receiver recorded the highest Coefficient of Performance (COP) of 2.55 but also had the highest energy usage at 1.90 kWh. In contrast, the configuration with 30% refrigerant fill in the receiver demonstrated optimal performance, achieving a 47% reduction in compressor power, the lowest energy consumption (1.01 kWh), and an evaporator temperature reaching –31°C. These improvements are attributed to more stable refrigerant flow, enhanced subcooling, and better pressure regulation enabled by the receiver. The use of a liquid receiver allowed for smoother thermodynamic operation, minimizing energy loss through irregular phase distribution. The findings suggest that fine-tuning the refrigerant charge within the receiver can significantly improve the system’s energy efficiency, without the need for extensive redesign of main components. This approach offers a simple, low-cost, and effective solution, especially relevant for household and small-scale commercial freezer applications where practicality and long-term savings are priorities

References

- Kong, D., Yin, X., Ding, X., Fang, N., Duan, P. (2021). Global optimization of a vapor compression refrigeration system with a self-adaptive differential evolution algorithm. Applied Thermal Engineering, 197, 117427. https://doi.org/10.1016/j.applthermaleng.2021.117427

- Mohite, S., Motgi, R., Dhalait, J. (2020). Experimental analysis on vapor compression refrigeration system by using eco-friendly refrigerant mixtures. International Journal of Innovations in Engineering Research and Technology. National Conference on Innovative Trends in Engineering & Technology, 9–12. Available at: https://repo.ijiert.org/index.php/ijiert/article/view/2307

- Solanki, N., Arora, A., Singh, R. K. (2023). Performance enhancement and environmental analysis of vapor compression refrigeration system with dedicated mechanical subcooling. International Journal of Air-Conditioning and Refrigeration, 31 (1). https://doi.org/10.1007/s44189-023-00042-8

- Nacak, C., Saraç, B. (2020). The performance assessment of a refrigeration system which exists on a cargo vessel influenced by seawater-intake temperature. Journal of Thermal Analysis and Calorimetry, 146 (3), 1229–1243. https://doi.org/10.1007/s10973-020-10060-y

- Chopra, K., Sahni, V., Mishra, R. S. (2014). Thermodynamic analyses of multiple evaporators vapor compression refrigeration systems with R410A, R290, R1234YF, R502, R404A, R152A and R134A. International Journal of Air-Conditioning and Refrigeration, 22 (01), 1450003. https://doi.org/10.1142/s2010132514500035

- Megdouli, K., Tashtoush, B. M., Ezzaalouni, Y., Nahdi, E., Mhimid, A., Kairouani, L. (2017). Performance analysis of a new ejector expansion refrigeration cycle (NEERC) for power and cold: Exergy and energy points of view. Applied Thermal Engineering, 122, 39–48. https://doi.org/10.1016/j.applthermaleng.2017.05.014

- Tambunan, A. H., Sihaloho, T. E., Kamal, D. M., Sitompul, J. P. (2012). Experimental study on the effect of freezing medium temperature on exergy efficiency. International Journal of Exergy, 10 (3), 321. https://doi.org/10.1504/ijex.2012.046813

- Sukusno, P., Setiawan, R. P. A., Purwanto, Y. A., Tambunan, A. H. (2019). Exergy analysis of refrigerator for a three steps freezing process. Cogent Engineering, 6 (1). https://doi.org/10.1080/23311916.2019.1637621

- Berman, E. T. (2015). Analysis of Quantity of Heat Absorption in a 90-Liter Capacity Domestic Refrigerator Using a Tube In Tube Heat Exchanger. Jurnal TORSI, XIII (1), 19–36.

- Luo, Y., Wang, X. (2010). Exergy analysis on throttle reduction efficiency based on real gas equations. Energy, 35 (1), 181–187. https://doi.org/10.1016/j.energy.2009.09.008

- Sako, M., Hatano, H., Yano, T. (2018). Calculating Energy Efficiency Index of VRF System by Supply-Air Temperature Estimation. 2018 IEEE 7th Global Conference on Consumer Electronics (GCCE), 815–817. https://doi.org/10.1109/gcce.2018.8574681

- Kartal, M. A., Atakök, G., Ersoy, S. (2024). Cooling and Multiphase Analysis of Heated Environmentally Friendly R152A (C2H4F2) Fluid Coming from the Production Process According to Nist Indicators. Applied Sciences, 14 (10), 4143. https://doi.org/10.3390/app14104143

- Lee, J.-H., Jung, H.-I., Lee, S.-B., Son, C.-H. (2024). Enhancing Semiconductor Chiller Performance: Investigating the Performance Characteristics of Ultra-Low-Temperature Chillers Applying a Liquid Receiver. Energies, 17 (20), 5144. https://doi.org/10.3390/en17205144

- Wu, J. M., Huang, X., Zhang, H. (2009). Numerical investigation on the heat and mass transfer in a direct evaporative cooler. Applied Thermal Engineering, 29 (1), 195–201. https://doi.org/10.1016/j.applthermaleng.2008.02.018

- Yang, Y., Cui, G., Lan, C. Q. (2019). Developments in evaporative cooling and enhanced evaporative cooling - A review. Renewable and Sustainable Energy Reviews, 113, 109230. https://doi.org/10.1016/j.rser.2019.06.037

- Cengel, Y., Boles, M. (2001). Thermodynamics: An Engineering Approach. Mcgraw-Hill College.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Paulus Sukusno, Banhur Nainggolan, Parulian Jannus, Ainun Nidhar, Tatun Hayatun Nufus, Haolia Rahman

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.