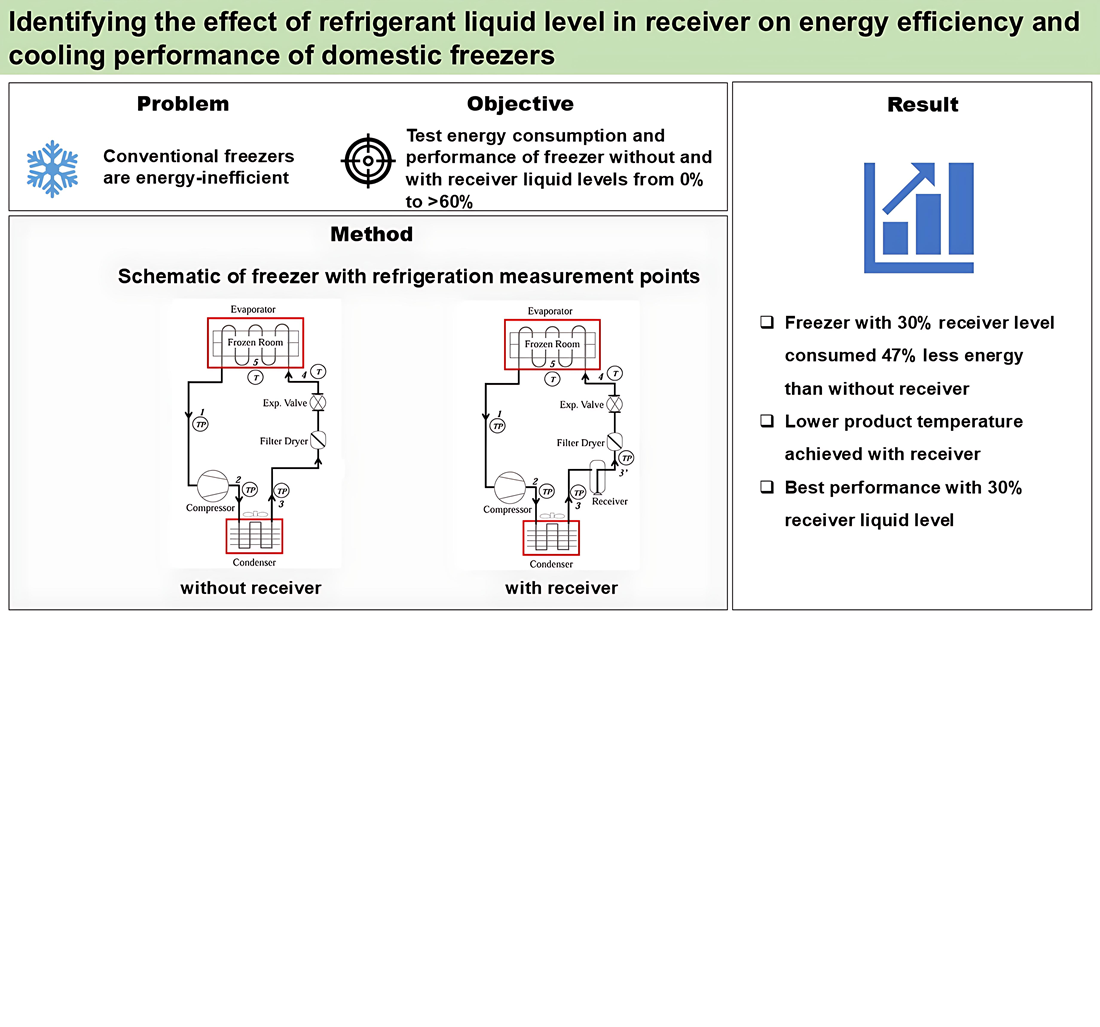

Визначення впливу рівня холодагента в ресивері на енергоефективність та продуктивність охолодження побутових морозильних камер

DOI:

https://doi.org/10.15587/1729-4061.2025.326761Ключові слова:

оптимізація заправки холодоагентом, динаміка рідинного ресивера, ефективність переохолодження, продуктивність побутової морозильної камери, поведінка системи R404AАнотація

У цьому дослідженні досліджується побутова система парокомпресійної морозильної камери, що використовує холодоагент R404A та компресор потужністю 0,75 кВт, з акцентом на вплив різних рівнів рідкого холодоагенту в ресивері на продуктивність системи та споживання енергії. Однією з основних проблем побутових морозильних камер є надмірне споживання енергії, особливо в системах, що не мають механізмів регулювання рідини, таких як ресивер. Для дослідження цього було розроблено експериментальну установку для тестування шести робочих умов: один без ресивера та п’ять з різним рівнем заповнення ресивера холодоагентом, від менш ніж 0% до понад 60%. Експериментальні результати показали, що морозильна камера без ресивера зафіксувала найвищий коефіцієнт продуктивності (COP) 2,55, але також мала найвище споживання енергії – 1,90 кВт‧год. Натомість конфігурація з 30% заповненням ресивера холодоагентом продемонструвала оптимальну продуктивність, досягнувши зниження потужності компресора на 47%, найнижчого споживання енергії (1,01 кВт⋅год) та температури випарника, що досягла –31°C. Ці покращення пояснюються стабільнішим потоком холодоагенту, покращеним переохолодженням та кращим регулюванням тиску, що забезпечується ресивером. Використання рідинного ресивера дозволило забезпечити плавнішу термодинамічну роботу, мінімізуючи втрати енергії через нерівномірний розподіл фаз. Результати дослідження свідчать про те, що точне налаштування заправки холодоагентом у ресивері може значно підвищити енергоефективність системи без необхідності значної переробки основних компонентів. Цей підхід пропонує просте, недороге та ефективне рішення, особливо актуальне для побутових та невеликих комерційних морозильних камер, де пріоритетами є практичність та довгострокова економія

Посилання

- Kong, D., Yin, X., Ding, X., Fang, N., Duan, P. (2021). Global optimization of a vapor compression refrigeration system with a self-adaptive differential evolution algorithm. Applied Thermal Engineering, 197, 117427. https://doi.org/10.1016/j.applthermaleng.2021.117427

- Mohite, S., Motgi, R., Dhalait, J. (2020). Experimental analysis on vapor compression refrigeration system by using eco-friendly refrigerant mixtures. International Journal of Innovations in Engineering Research and Technology. National Conference on Innovative Trends in Engineering & Technology, 9–12. Available at: https://repo.ijiert.org/index.php/ijiert/article/view/2307

- Solanki, N., Arora, A., Singh, R. K. (2023). Performance enhancement and environmental analysis of vapor compression refrigeration system with dedicated mechanical subcooling. International Journal of Air-Conditioning and Refrigeration, 31 (1). https://doi.org/10.1007/s44189-023-00042-8

- Nacak, C., Saraç, B. (2020). The performance assessment of a refrigeration system which exists on a cargo vessel influenced by seawater-intake temperature. Journal of Thermal Analysis and Calorimetry, 146 (3), 1229–1243. https://doi.org/10.1007/s10973-020-10060-y

- Chopra, K., Sahni, V., Mishra, R. S. (2014). Thermodynamic analyses of multiple evaporators vapor compression refrigeration systems with R410A, R290, R1234YF, R502, R404A, R152A and R134A. International Journal of Air-Conditioning and Refrigeration, 22 (01), 1450003. https://doi.org/10.1142/s2010132514500035

- Megdouli, K., Tashtoush, B. M., Ezzaalouni, Y., Nahdi, E., Mhimid, A., Kairouani, L. (2017). Performance analysis of a new ejector expansion refrigeration cycle (NEERC) for power and cold: Exergy and energy points of view. Applied Thermal Engineering, 122, 39–48. https://doi.org/10.1016/j.applthermaleng.2017.05.014

- Tambunan, A. H., Sihaloho, T. E., Kamal, D. M., Sitompul, J. P. (2012). Experimental study on the effect of freezing medium temperature on exergy efficiency. International Journal of Exergy, 10 (3), 321. https://doi.org/10.1504/ijex.2012.046813

- Sukusno, P., Setiawan, R. P. A., Purwanto, Y. A., Tambunan, A. H. (2019). Exergy analysis of refrigerator for a three steps freezing process. Cogent Engineering, 6 (1). https://doi.org/10.1080/23311916.2019.1637621

- Berman, E. T. (2015). Analysis of Quantity of Heat Absorption in a 90-Liter Capacity Domestic Refrigerator Using a Tube In Tube Heat Exchanger. Jurnal TORSI, XIII (1), 19–36.

- Luo, Y., Wang, X. (2010). Exergy analysis on throttle reduction efficiency based on real gas equations. Energy, 35 (1), 181–187. https://doi.org/10.1016/j.energy.2009.09.008

- Sako, M., Hatano, H., Yano, T. (2018). Calculating Energy Efficiency Index of VRF System by Supply-Air Temperature Estimation. 2018 IEEE 7th Global Conference on Consumer Electronics (GCCE), 815–817. https://doi.org/10.1109/gcce.2018.8574681

- Kartal, M. A., Atakök, G., Ersoy, S. (2024). Cooling and Multiphase Analysis of Heated Environmentally Friendly R152A (C2H4F2) Fluid Coming from the Production Process According to Nist Indicators. Applied Sciences, 14 (10), 4143. https://doi.org/10.3390/app14104143

- Lee, J.-H., Jung, H.-I., Lee, S.-B., Son, C.-H. (2024). Enhancing Semiconductor Chiller Performance: Investigating the Performance Characteristics of Ultra-Low-Temperature Chillers Applying a Liquid Receiver. Energies, 17 (20), 5144. https://doi.org/10.3390/en17205144

- Wu, J. M., Huang, X., Zhang, H. (2009). Numerical investigation on the heat and mass transfer in a direct evaporative cooler. Applied Thermal Engineering, 29 (1), 195–201. https://doi.org/10.1016/j.applthermaleng.2008.02.018

- Yang, Y., Cui, G., Lan, C. Q. (2019). Developments in evaporative cooling and enhanced evaporative cooling - A review. Renewable and Sustainable Energy Reviews, 113, 109230. https://doi.org/10.1016/j.rser.2019.06.037

- Cengel, Y., Boles, M. (2001). Thermodynamics: An Engineering Approach. Mcgraw-Hill College.

##submission.downloads##

Опубліковано

Як цитувати

Номер

Розділ

Ліцензія

Авторське право (c) 2025 Paulus Sukusno, Banhur Nainggolan, Parulian Jannus, Ainun Nidhar, Tatun Hayatun Nufus, Haolia Rahman

Ця робота ліцензується відповідно до Creative Commons Attribution 4.0 International License.

Закріплення та умови передачі авторських прав (ідентифікація авторства) здійснюється у Ліцензійному договорі. Зокрема, автори залишають за собою право на авторство свого рукопису та передають журналу право першої публікації цієї роботи на умовах ліцензії Creative Commons CC BY. При цьому вони мають право укладати самостійно додаткові угоди, що стосуються неексклюзивного поширення роботи у тому вигляді, в якому вона була опублікована цим журналом, але за умови збереження посилання на першу публікацію статті в цьому журналі.

Ліцензійний договір – це документ, в якому автор гарантує, що володіє усіма авторськими правами на твір (рукопис, статтю, тощо).

Автори, підписуючи Ліцензійний договір з ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР», мають усі права на подальше використання свого твору за умови посилання на наше видання, в якому твір опублікований. Відповідно до умов Ліцензійного договору, Видавець ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР» не забирає ваші авторські права та отримує від авторів дозвіл на використання та розповсюдження публікації через світові наукові ресурси (власні електронні ресурси, наукометричні бази даних, репозитарії, бібліотеки тощо).

За відсутності підписаного Ліцензійного договору або за відсутністю вказаних в цьому договорі ідентифікаторів, що дають змогу ідентифікувати особу автора, редакція не має права працювати з рукописом.

Важливо пам’ятати, що існує і інший тип угоди між авторами та видавцями – коли авторські права передаються від авторів до видавця. В такому разі автори втрачають права власності на свій твір та не можуть його використовувати в будь-який спосіб.