Features of heating and melting of powder tape for surfacing of composite and complex-alloyed alloys

DOI:

https://doi.org/10.15587/1729-4061.2025.327904Keywords:

powder tape, thermal state, core, surfacing, composite alloy, alloyed alloyAbstract

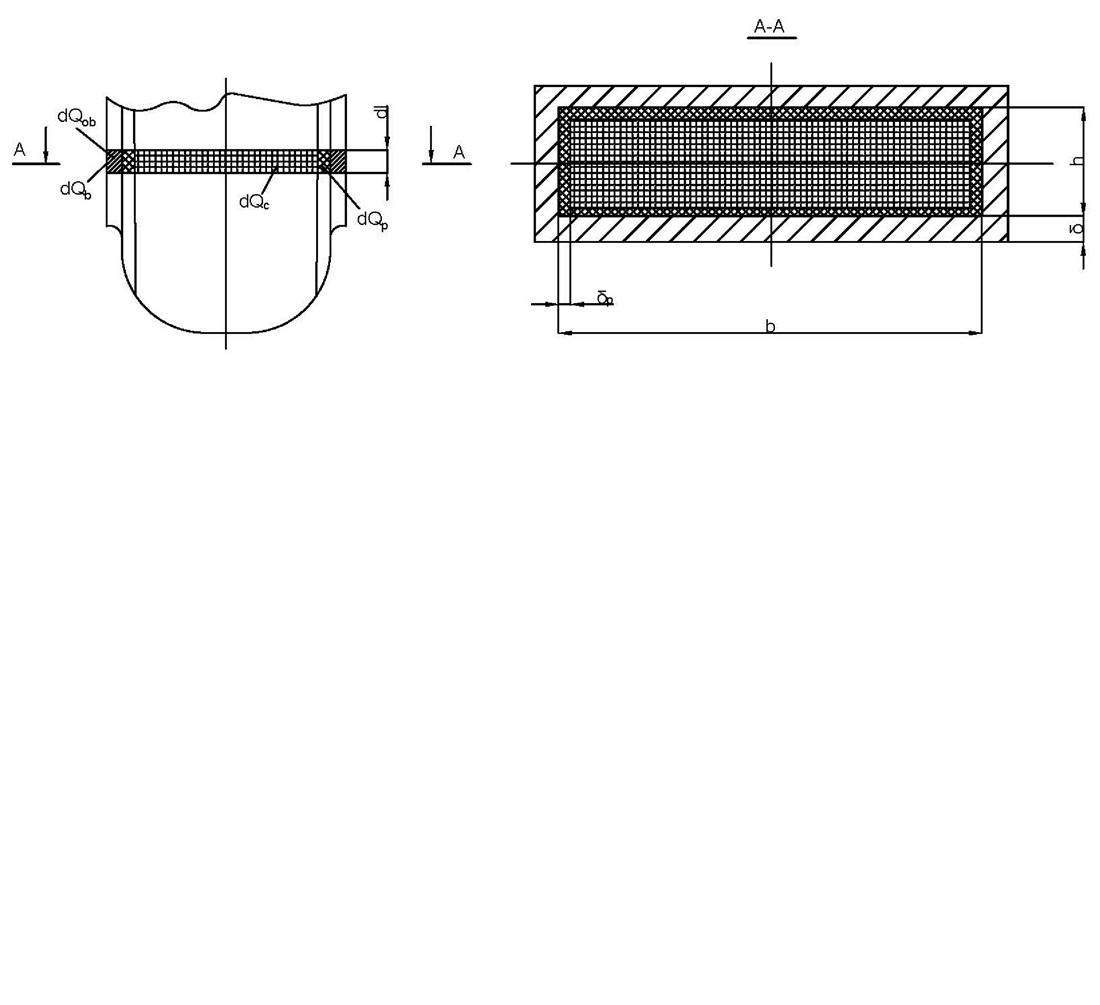

The object of this study is a powder tape for arc surfacing of composite and complex-alloyed alloys. Essentially, the peculiarities of their design determine the uneven heating and melting of the shell and core during the arc surfacing process. This causes chemical heterogeneity of the surfacing metal, which leads to a spread of its mechanical properties. Taking into account the thermal balance of heating the powder tape protrusion by the welding current during surfacing, a mathematical model has been built. It allows for a reliable and operational assessment of thermal effects depending on the welding current density, geometric dimensions, the filler metal filling ratio of the tape and the thermophysical characteristics of the metal shell and ingredients. Its quantitative accuracy makes it possible to predict general patterns of temperature differences, changes in the aggregate state, heat and mass transfer, and phase transitions. It also allows for the calculation of the direction and limits of physicochemical reactions and the identification of ways to control the power parameters of the powder tape manufacturing process and the characteristics of the surfacing mode.

Comparison of the calculated values of the average heating temperature with experimental data indicates the adequacy of the mathematical model and its feasibility for practical calculations. The data reported in the paper correctly reflect the nature of the heating of the powder tape, taking into account the composition of the core, the thickness of the shell, the size of the tape, the degree of compression of the metal shell and the powder core in the two-roll mill stand. Analytical description of the heating patterns makes it possible to solve under industrial conditions the technological tasks of improving the quality of the deposited metal, increasing the productivity of the process, as well as resource and energy saving when surfacing composite and alloyed wear-resistant alloys

References

- Yang, X. (2015). Analysis of Chinese Welding Industries Today and in the Future (Focus on Cost, Productivity, and Quality). International Journal of Mechanical Engineering and Applications, 3 (6), 127. https://doi.org/10.11648/j.ijmea.20150306.15

- Voronchuk, O. P., Zhudra, O. P., Kaida, T. V., Petrov, O. V., Kapitanchuk, L. M., Bogaichuk, I. L. (2022). Influence of the composition of charge components of flux-cored strips of C–Fe–Cr–Nb alloying system on chemical composition and structure of the deposited metal. Automatic Welding, 8, 29–34. https://doi.org/10.37434/as2022.08.04

- Prysyazhnyuk, P., Ivanov, O., Matvienkiv, O., Marynenko, S., Korol, O., Koval, I. (2022). Impact and abrasion wear resistance of the hardfacings based on high-manganese steel reinforced with multicomponent carbides of Ti-Nb-Mo-V-C system. Procedia Structural Integrity, 36, 130–136. https://doi.org/10.1016/j.prostr.2022.01.014

- Gribkov, E. P., Perig, A. V. (2016). Research of energy-power parameters during powder wire flattening. The International Journal of Advanced Manufacturing Technology, 85 (9-12), 2887–2900. https://doi.org/10.1007/s00170-016-8714-1

- Gribkov, E. P., Malyhin, S. O., Hurkovskaya, S. S., Berezshnaya, E. V., Merezhko, D. V. (2022). Mathematical modelling, study and computer-aided design of flux-cored wire rolling in round gauges. The International Journal of Advanced Manufacturing Technology, 119 (7-8), 4249–4263. https://doi.org/10.1007/s00170-022-08662-x

- Gomes, J. H. F., Costa, S. C., Paiva, A. P., Balestrassi, P. P. (2012). Mathematical Modeling of Weld Bead Geometry, Quality, and Productivity for Stainless Steel Claddings Deposited by FCAW. Journal of Materials Engineering and Performance, 21 (9), 1862–1872. https://doi.org/10.1007/s11665-011-0103-1

- Mutașcu, D., Karancsi, O., Mitelea, I., Crăciunescu, C. M., Buzdugan, D., Uțu, I.-D. (2023). Pulsed TIG Cladding of a Highly Carbon-, Chromium-, Molybdenum-, Niobium-, Tungsten- and Vanadium-Alloyed Flux-Cored Wire Electrode on Duplex Stainless Steel X2CrNiMoN 22-5-3. Materials, 16 (13), 4557. https://doi.org/10.3390/ma16134557

- Guo, N., Zhang, X., Fu, Y., Luo, W., Chen, H., Long He, J. (2023). A novel strategy to prevent hydrogen charging via spontaneously molten-slag-covering droplet transfer mode in underwater wet FCAW. Materials & Design, 226, 111636. https://doi.org/10.1016/j.matdes.2023.111636

- Trembach, B., Grin, A., Turchanin, M., Makarenko, N., Markov, O., Trembach, I. (2021). Application of Taguchi method and ANOVA analysis for optimization of process parameters and exothermic addition (CuO-Al) introduction in the core filler during self-shielded flux-cored arc welding. The International Journal of Advanced Manufacturing Technology, 114 (3-4), 1099–1118. https://doi.org/10.1007/s00170-021-06869-y

- Tippayasam, C., Taengwa, C., Palomas, J., Siripongsakul, T., Thaweechai, T., Kaewvilai, A. (2023). Effects of flux-cored arc welding technology on microstructure and wear resistance of Fe-Cr-C hardfacing alloy. Materials Today Communications, 35, 105569. https://doi.org/10.1016/j.mtcomm.2023.105569

- Świerczyńska, A., Varbai, B., Pandey, C., Fydrych, D. (2023). Exploring the trends in flux-cored arc welding: scientometric analysis approach. The International Journal of Advanced Manufacturing Technology, 130 (1-2), 87–110. https://doi.org/10.1007/s00170-023-12682-6

- Kannan, T., Murugan, N. (2006). Effect of flux cored arc welding process parameters on duplex stainless steel clad quality. Journal of Materials Processing Technology, 176 (1-3), 230–239. https://doi.org/10.1016/j.jmatprotec.2006.03.157

- Chen, S. B., Lv, N. (2014). Research evolution on intelligentized technologies for arc welding process. Journal of Manufacturing Processes, 16 (1), 109–122. https://doi.org/10.1016/j.jmapro.2013.07.002

- Hirata, Y. (1995). Physics of welding (III) ‐ Melting rate and temperature distribution of electrode wire. Welding International, 9 (5), 348–351. https://doi.org/10.1080/09507119509548811

- Karwa, R. (2020). Heat and Mass Transfer. Springer Singapore. https://doi.org/10.1007/978-981-15-3988-6

- Forsberg, C. H. (2020). Heat transfer principles and applications. Academic Press. https://doi.org/10.1016/c2014-0-02744-x

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Valeriy Kassov, Olena Berezshna, Svitlana Yermakova, Dmytro Turchanin, Svetlana Malyhina

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.