Modification of structural and mechanical properties of the extrudate by enrichment with food fibers and lipids

DOI:

https://doi.org/10.15587/1729-4061.2025.330564Keywords:

extrudate, dietary fiber, chicken fat, protein-starch matrix, structural and mechanical properties, swelling indexAbstract

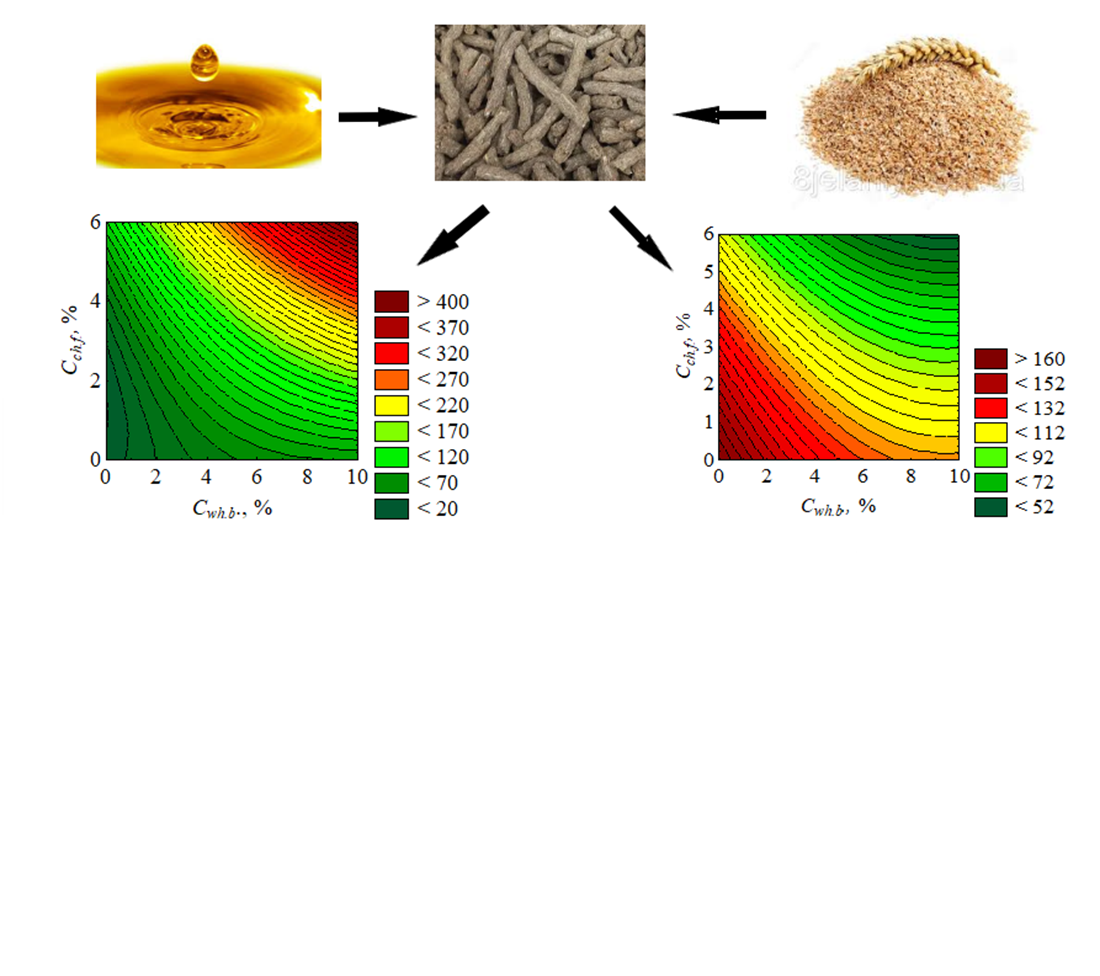

The object of the study is the composition of the feed extrudate modified by the addition of dietary fiber and lipid sources. The problem to be solved is the optimization of the structural and mechanical properties of the feed extrudate through the rationalization of the addition of components. Regression models have been developed to accurately predict the ratio of modifying additives that provides the specified water resistance and swelling index. It has been experimentally established that the rational ratio of components – 4.0±0.1 % chicken fat and 6.0±0.2 % wheat bran – provides water resistance of 190.0±7.5 min, swelling index of 55.0±2.1 % and porosity of 60.0±2.2 %. The results are achieved due to the complex interaction between the components, where lipids form a hydrophobic barrier, and dietary fibers create a stable porous matrix, which is confirmed by regression models. Comparative analysis with a commercial analogue (“Roycher™ AQUA Carp Finish”) revealed competitive advantages of the developed extrudate: lower cost (310 USD/t versus 1050 USD/t). Structural and mechanical characteristics of the studied extrudates were similar. This makes the developed composition promising for industrial application. The results obtained are explained by the interaction of the protein-starch matrix with lipids and dietary fibers during extrusion, which is confirmed by statistically significant models. A distinctive feature of the study is a comprehensive approach to rationalizing the composition of the extrudate, which combines technological efficiency with economic feasibility. The extrudate of the developed composition can be used in the production of feed for aquaculture. Further research should be aimed at studying the long-term stability of product properties and adapting the technology to industrial conditions

References

- Aschemann-Witzel, J., Gantriis, R. F., Fraga, P., Perez-Cueto, F. J. A. (2020). Plant-based food and protein trend from a business perspective: markets, consumers, and the challenges and opportunities in the future. Critical Reviews in Food Science and Nutrition, 61 (18), 3119–3128. https://doi.org/10.1080/10408398.2020.1793730

- Petik, I., Litvinenko, O., Kalyna, V., Ilinska, O., Raiko, V., Filenko, O. et al. (2023). Development of extruded animal feed based on fat and oil industry waste. Eastern-European Journal of Enterprise Technologies, 2 (11 (122)), 112–120. https://doi.org/10.15587/1729-4061.2023.275509

- Singh, J. P., Kaur, A., Singh, B., Singh, N., Singh, B. (2019). Physicochemical evaluation of corn extrudates containing varying buckwheat flour levels prepared at various extrusion temperatures. Journal of Food Science and Technology, 56 (4), 2205–2212. https://doi.org/10.1007/s13197-019-03703-y

- Bochkarev, S., Chaika, T., Stankevych, S., Zabrodina, I., Balandina, I., Obolentseva, L. et al. (2024). Development of an extruded system with enhanced content of alpha-linolenic polyunsaturated fatty acid. Eastern-European Journal of Enterprise Technologies, 6 (11 (132)), 15–23. https://doi.org/10.15587/1729-4061.2024.315246

- Stankevych, S., Gorbunov, K., Zabrodina, I., Popov, M., Kalyna, V., Novozhylova, T. et al. (2024). Identification of the oxidation and hydrolysis products content influence on the rapeseed oil oxidation induction period. Eastern-European Journal of Enterprise Technologies, 4 (6 (130)), 6–13. https://doi.org/10.15587/1729-4061.2024.308907

- Belinska, A., Ryshchenko, I., Bliznjuk, O., Masalitina, N., Siedykh, K., Zolotarova, S. et al. (2024). Development of a method for inactivating lipoxygenases in linseed using chemical reagents. Eastern-European Journal of Enterprise Technologies, 4 (6 (130)), 14–21. https://doi.org/10.15587/1729-4061.2024.309079

- Siddiqui, S. A., Kamran, F., Stankov, S., Rathod, N. B., Teixeira-Costa, B. E., Fidan, H. et al. (2024). Unveiling the Diversity of Non Conventional Proteins - From Sources, Extraction, Technofunctionality, Nutraceutical Potential to Advancement in Food Applications - A Systematic Review. Waste and Biomass Valorization, 16 (1), 29–51. https://doi.org/10.1007/s12649-024-02614-0

- Papchenko, V., Stepankova, G., Karatieieva, O., Balandina, I., Shapovalenko, D., Kariuk, A., Statyvka, Y., Bakumenko, O., Melnyk, A., Нorbas, S. (2023). Determining the effect of raw materials moisture and lipid content on the technological properties of the extruded protein-fat system. Eastern-European Journal of Enterprise Technologies, 4 (11 (124)), 37–46. https://doi.org/10.15587/1729-4061.2023.285132

- Luthra, A., Kajla, P., Chhikara, N., Khatkar, B. S., Malik, M. (2025). Food and Dairy By-products Utilization. Engineering Solutions for Sustainable Food and Dairy Production, 331–344. https://doi.org/10.1007/978-3-031-75834-8_12

- Gutierrez-Montiel, E., Ávila-Orta, C. A., Cabrera-Canales, Z. E., Covarrubias-Gordillo, C. A., Reyes-Rodríguez, P. Y., Rodríguez-Velázquez, J. G. et al. (2023). Effect of oxidized, maleate and dual chemical modification through extrusion on thermoplastic starch properties. Polymer Bulletin, 81 (3), 2525–2544. https://doi.org/10.1007/s00289-023-04857-8

- Wang, B., Dong, Y., Fang, Y., Gao, W., Kang, X., Liu, P. et al. (2022). Effects of different moisture contents on the structure and properties of corn starch during extrusion. Food Chemistry, 368, 130804. https://doi.org/10.1016/j.foodchem.2021.130804

- Gomes, K. S., Berwian, G. F., Batistella, V. M. C., Bender, L. E., Reinehr, C. O., Colla, L. M. (2022). Nutritional and Technological Aspects of the Production of Proteic Extruded Snacks Added of Novel Raw Materials. Food and Bioprocess Technology, 16 (2), 247–267. https://doi.org/10.1007/s11947-022-02887-0

- Cervantes-Ramírez, J. E., Cabrera-Ramirez, A. H., Morales-Sánchez, E., Rodriguez-García, M. E., Reyes-Vega, M. de la L., Ramírez-Jiménez, A. K. et al. (2020). Amylose-lipid complex formation from extruded maize starch mixed with fatty acids. Carbohydrate Polymers, 246, 116555. https://doi.org/10.1016/j.carbpol.2020.116555

- Cabrera-Ramírez, A. H., Cervantes-Ramírez, E., Morales-Sánchez, E., Rodriguez-García, M. E., Reyes-Vega, M. de la L., Gaytán-Martínez, M. (2021). Effect of Extrusion on the Crystalline Structure of Starch during RS5 Formation. Polysaccharides, 2 (1), 187–201. https://doi.org/10.3390/polysaccharides2010013

- Qi, M., Jiang, L., Song, J., Han, F., Xu, M., Li, Y. et al. (2024). Investigating the Impact of Moisture Levels on Structural Alterations and Physicochemical Properties of Cassava Flour through Extrusion: A Comprehensive Study. Plant Foods for Human Nutrition, 79 (4), 909–914. https://doi.org/10.1007/s11130-024-01237-z

- Tiwari, A., Jha, S. K. (2017). Extrusion cooking technology: Principal mechanism and effect on direct expanded snacks – An overview. International Journal of Food Studies, 6 (1), 113–128. https://doi.org/10.7455/ijfs/6.1.2017.a10

- Banjac, V., Vukmirović, Đ., Pezo, L., Draganovic, V., Đuragić, O., Čolović, R. (2021). Impact of variability in protein content of sunflower meal on the extrusion process and physical quality of the extruded salmonid feed. Journal of Food Process Engineering, 44 (3). https://doi.org/10.1111/jfpe.13640

- Petik, I., Litvinenko, O., Stankevych, S., Zabrodina, I., Ponomarova, M., Kotliar, O. et al. (2024). Determination of the cellulose- and lipid-containing components influence on the extrudate technological indicators. Eastern-European Journal of Enterprise Technologies, 2 (6 (128)), 6–13. https://doi.org/10.15587/1729-4061.2024.301843

- Pennells, J., Bless, I., Juliano, P., Ying, D. (2024). Extrusion Processing of Biomass By-Products for Sustainable Food Production. From Biomass to Biobased Products. https://doi.org/10.5772/intechopen.111943

- Roycher Aqua fish feed. Roycher Aqua. Available at: https://roycheraqua.com/ua/

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Ihor Petik, Serhii Stankevych, Volodymyr Panasenko, Kostiantyn Siedykh, Maryna Ponomarova, Olesia Filenko, Iryna Balandina, Anton Ryabev, Svitlana Zolotarova, Viktoriia Novikova

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.