Construction of a physical-mechanical model of reinforcing microrelief formation on profiled strips made of AISI 1005 and AISI 347 steels considering surface topology

DOI:

https://doi.org/10.15587/1729-4061.2025.331742Keywords:

strengthening microrelief, texturing, surface topography, diamond indenter, folding systems, profilogramsAbstract

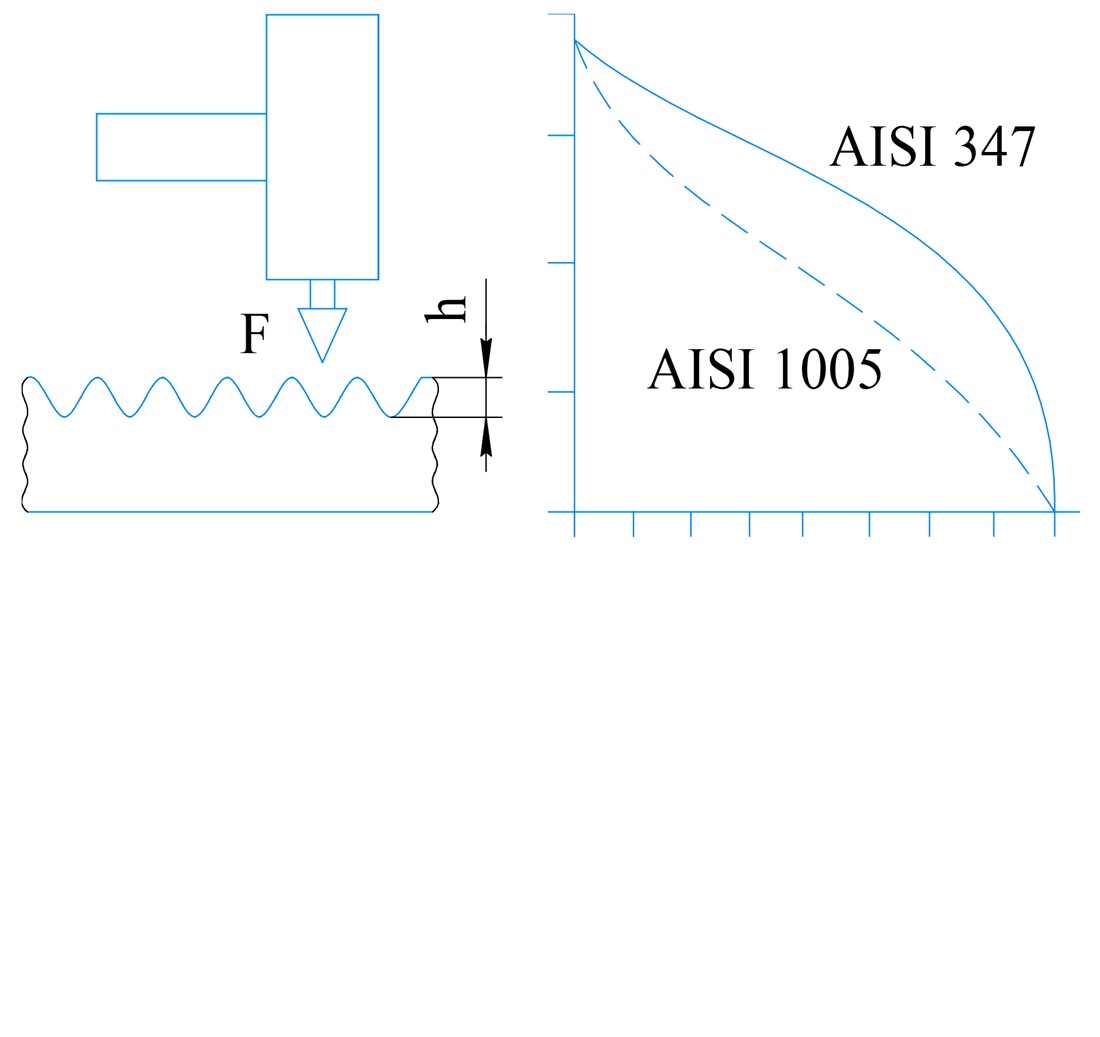

This study’s object is the process that forms a strengthening microrelief on the surface of profiled folding plates made of AISI 1005 and AISI 347 steels through localized indentation using a spherical indenter made of a diamond-based composite material. The principal hypothesis of the study posits that the implementation of a controlled surface texturing process enables the formation of a stable microrelief with predefined geometric characteristics. Achieving this requires establishing the regularities of microrelief formation depending on the physical and mechanical properties of the material, the geometry of the indenter, and the parameters of the contact interaction. A physical and mechanical model of the contact interaction between the indenter and the metallic plate has been built. The results of the analytical modeling were validated through profilometric measurements and 3D visualizations, which revealed differences in the depth and nature of deformation between AISI 1005 and AISI 347. The AISI 1005 steel exhibited higher plasticity and a greater tendency toward deep deformation, whereas AISI 347 demonstrated superior stability in the relief geometry. An evaluation of surface roughness parameters (Ra, Rz, Rmax) indicated that the AISI 347 steel provides better reproducibility of the strengthening effect, with average Ra and Rz values being 2–2.5 times lower than those of AISI 1005. The correlation analysis of microrelief parameters revealed a strong relationship between Ra and Rz values, with a correlation coefficient ranging from 0.93 to 0.96. This finding confirms the stability of the microrelief formation mechanism and justifies the use of AISI 347 steel in combination with a Ø3.5 mm indenter. The results of this study can be applied for manufacturing folding elements with enhanced wear resistance and geometric stability under cyclic loading conditions

References

- Kyrychok, P., Paliukh, D. (2024). Determining of the effect of reinforcing microrelief guides on the efficiency of folding integrated covers. Eastern-European Journal of Enterprise Technologies, 4 (1 (130)), 97–111. LOCKSS. https://doi.org/10.15587/1729-4061.2024.309481

- Dzyura, V., Maruschak, P., Semehen, V., Holovko, V., Fediv, V. (2023). Justification of the Parameters of Regular Microreliefs Formed on Flat Surfaces. Central Ukrainian Scientific Bulletin. Technical Sciences, 1 (8 (39)), 37–47. https://doi.org/10.32515/2664-262x.2023.8(39).1.37-47

- Tulupov, V., Onyshchuk, S. (2021). Research of surface reinforcement technologies for machine details. Technical Sciences and Technologies, 3 (25), 55–60. https://doi.org/10.25140/2411-5363-2021-3(25)-55-60

- Posuvailo, V., Shovkoplias, M., Romaniv, M., Malinin, V. (2021). Comparison of methods of surface strengthening of machine parts by coatings . Bulletin of Cherkasy State Technological University, 26 (4), 83–97. https://doi.org/10.24025/2306-4412.4.2021.253298

- Maksymuk, O. V. (2020). The peculiarities in contact interaction and wear of thin-walled elements of construction. Matematychni Metody Ta Fizyko-Mekhanichni Polya, 63 (1). https://doi.org/10.15407/mmpmf2020.63.1.133-148

- Slavov, S. D., Dimitrov, D. M., Mincheva, D. Y., Dzyura, V., Maruschak, P., Semehen, V. (2025). Microstructure and Microhardness Research of Steel 304 After Forming Partially Regular Reliefs by Ball Burnishing Operation. Materials, 18 (7), 1565. https://doi.org/10.3390/ma18071565

- Zhang, L., Wu, Z. (2023). A mini-review of surface severe plastic deformation methods and their effects on steel and stainless steel. Proceedings of the Institution of Mechanical Engineers, Part L: Journal of Materials: Design and Applications, 238 (3), 397–415. https://doi.org/10.1177/14644207231190491

- Cao, S. C., Zhang, X., Lu, J., Wang, Y., Shi, S.-Q., Ritchie, R. O. (2019). Predicting surface deformation during mechanical attrition of metallic alloys. Npj Computational Materials, 5 (1). https://doi.org/10.1038/s41524-019-0171-6

- Wang, G., Tong, Y., Liang, L., Zhang, M., Zhao, M., Li, L. (2025). Indentation deformation mechanism of combined-strengthened modified layer in low-alloy steel under the influence of hydrogen. Corrosion Science, 242, 112579. https://doi.org/10.1016/j.corsci.2024.112579

- Luo, Q., Kitchen, M. (2023). Microhardness, Indentation Size Effect and Real Hardness of Plastically Deformed Austenitic Hadfield Steel. Materials, 16 (3), 1117. https://doi.org/10.3390/ma16031117

- Shen, Z., Su, Y., Liang, Z., Long, X. (2024). Review of indentation size effect in crystalline materials: Progress, challenges and opportunities. Journal of Materials Research and Technology, 31, 117–132. https://doi.org/10.1016/j.jmrt.2024.06.071

- Shul’zhenko, A. A., Jaworska, L., Sokolov, A. N., Romanko, L. A., Gargin, V. G., Belyavina, N. N. et al. (2018). Structure and Electrophysical Properties of the Diamond–Graphen–Silicon Carbide Composite. Journal of Superhard Materials, 40 (6), 435–438. https://doi.org/10.3103/s1063457618060102

- Skripchenko, N., Tkachuk, М., Nedilko, K., Kyrychuk, D, Borysenko, S., Kasai, O. (2016). Contact interaction of complex-shaped details with local compliance of the surface layer. Bulletin of NTU "KhPI". Series: Engineering and CAD, 39 (1211), 93–101. Available at: https://repository.kpi.kharkov.ua/server/api/core/bitstreams/a6ff27d4-67bc-4980-a387-bce9abed66e6/content

- Properties and Selection: Irons, Steels, and High-Performance Alloys (1990). ASM Handbook. https://doi.org/10.31399/asm.hb.v01.9781627081610

- AISI 347 Stainless Steel Datasheet. Ferrobend.

- Schober, P., Boer, C., Schwarte, L. A. (2018). Correlation Coefficients: Appropriate Use and Interpretation. Anesthesia & Analgesia, 126 (5), 1763–1768. https://doi.org/10.1213/ane.0000000000002864

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Petro Kyrychok, Dmytro Paliukh

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.