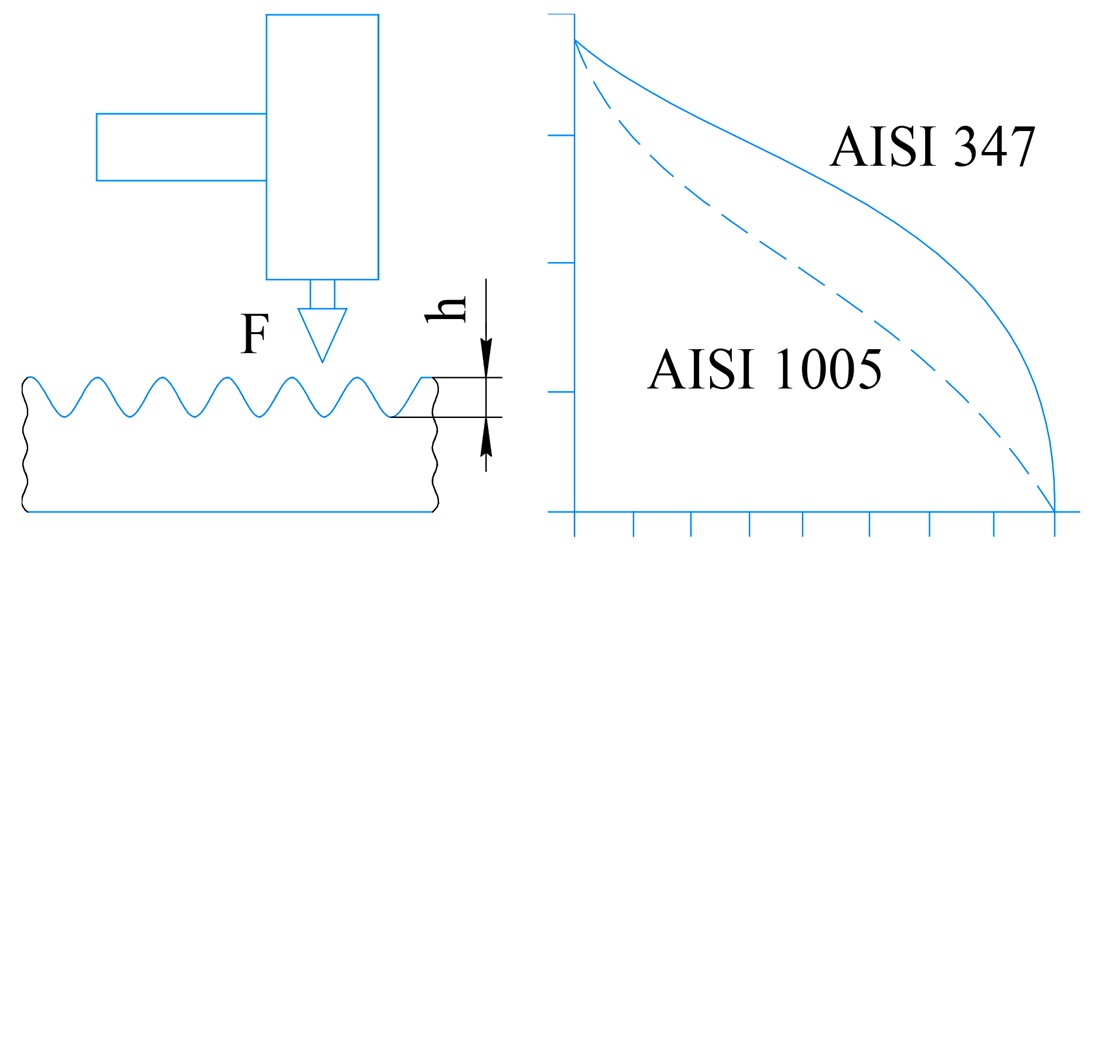

Розробка фізико-механічної моделі формування зміцнювального мікрорельєфу на профільних планках зі сталей AISI 1005 і AISI 347 з урахуванням топології поверхні

DOI:

https://doi.org/10.15587/1729-4061.2025.331742Ключові слова:

зміцнювальний мікрорельєф, текстурування, топологія поверхні, алмазний індентор, фальцювальні системи, профілограмиАнотація

Об'єктом дослідження є процес формування зміцнювального мікрорельєфу на поверхні профільних фальцювальних планок зі сталей AISI 1005 та AISI 347 шляхом локального вдавлювання сферичного індентора, виготовленого з алмазного композиційного матеріалу. Основне припущення дослідження полягає в тому, що реалізація керованої технології текстурування забезпечує формування стабільного мікрорельєфу із заданими геометричними параметрами. Цього не можливо досягнути без встановлення закономірностей утворення зміцнювального рельєфу залежно від фізико-механічних властивостей матеріалу, геометрії інструмента та режимів контактної дії. Побудовано фізико-механічну модель контактної взаємодії індентора з металевою пластиною. Результати аналітичного моделювання узгоджено з профілометричними вимірюваннями та 3D-візуалізаціями, які засвідчили відмінності у глибині та характері деформації для AISI 1005 і AISI 347. Сталь AISI 1005 виявила більшу пластичність і схильність до глибокої деформації, тоді як AISI 347 забезпечила вищу стабільність геометрії рельєфу. Оцінка параметрів шорсткості (Ra, Rz, Rmax) показала, що сталь AISI 347 характеризується вищою відтворюваністю зміцнення, при цьому середні значення Ra і Rz для цієї сталі у 2–2,5 рази нижчі, ніж у сталі AISI 1005. Проведений кореляційний аналіз взаємозв’язку між параметрами рельєфу виявив тісний зв’язок між показниками Ra та Rz (коефіцієнт кореляції 0.93–0.96). Це свідчить про стабільність механізму формування мікрорельєфу та обґрунтовує доцільність використання сталі AISI 347 у поєднанні з індентором Ø3,5 мм. Результати дослідження можуть бути впроваджені у виготовлення фальцювальних елементів із підвищеною зносостійкістю та геометричною стабільністю в умовах циклічного навантаження

Посилання

- Kyrychok, P., Paliukh, D. (2024). Determining of the effect of reinforcing microrelief guides on the efficiency of folding integrated covers. Eastern-European Journal of Enterprise Technologies, 4 (1 (130)), 97–111. LOCKSS. https://doi.org/10.15587/1729-4061.2024.309481

- Dzyura, V., Maruschak, P., Semehen, V., Holovko, V., Fediv, V. (2023). Justification of the Parameters of Regular Microreliefs Formed on Flat Surfaces. Central Ukrainian Scientific Bulletin. Technical Sciences, 1 (8 (39)), 37–47. https://doi.org/10.32515/2664-262x.2023.8(39).1.37-47

- Tulupov, V., Onyshchuk, S. (2021). Research of surface reinforcement technologies for machine details. Technical Sciences and Technologies, 3 (25), 55–60. https://doi.org/10.25140/2411-5363-2021-3(25)-55-60

- Posuvailo, V., Shovkoplias, M., Romaniv, M., Malinin, V. (2021). Comparison of methods of surface strengthening of machine parts by coatings . Bulletin of Cherkasy State Technological University, 26 (4), 83–97. https://doi.org/10.24025/2306-4412.4.2021.253298

- Maksymuk, O. V. (2020). The peculiarities in contact interaction and wear of thin-walled elements of construction. Matematychni Metody Ta Fizyko-Mekhanichni Polya, 63 (1). https://doi.org/10.15407/mmpmf2020.63.1.133-148

- Slavov, S. D., Dimitrov, D. M., Mincheva, D. Y., Dzyura, V., Maruschak, P., Semehen, V. (2025). Microstructure and Microhardness Research of Steel 304 After Forming Partially Regular Reliefs by Ball Burnishing Operation. Materials, 18 (7), 1565. https://doi.org/10.3390/ma18071565

- Zhang, L., Wu, Z. (2023). A mini-review of surface severe plastic deformation methods and their effects on steel and stainless steel. Proceedings of the Institution of Mechanical Engineers, Part L: Journal of Materials: Design and Applications, 238 (3), 397–415. https://doi.org/10.1177/14644207231190491

- Cao, S. C., Zhang, X., Lu, J., Wang, Y., Shi, S.-Q., Ritchie, R. O. (2019). Predicting surface deformation during mechanical attrition of metallic alloys. Npj Computational Materials, 5 (1). https://doi.org/10.1038/s41524-019-0171-6

- Wang, G., Tong, Y., Liang, L., Zhang, M., Zhao, M., Li, L. (2025). Indentation deformation mechanism of combined-strengthened modified layer in low-alloy steel under the influence of hydrogen. Corrosion Science, 242, 112579. https://doi.org/10.1016/j.corsci.2024.112579

- Luo, Q., Kitchen, M. (2023). Microhardness, Indentation Size Effect and Real Hardness of Plastically Deformed Austenitic Hadfield Steel. Materials, 16 (3), 1117. https://doi.org/10.3390/ma16031117

- Shen, Z., Su, Y., Liang, Z., Long, X. (2024). Review of indentation size effect in crystalline materials: Progress, challenges and opportunities. Journal of Materials Research and Technology, 31, 117–132. https://doi.org/10.1016/j.jmrt.2024.06.071

- Shul’zhenko, A. A., Jaworska, L., Sokolov, A. N., Romanko, L. A., Gargin, V. G., Belyavina, N. N. et al. (2018). Structure and Electrophysical Properties of the Diamond–Graphen–Silicon Carbide Composite. Journal of Superhard Materials, 40 (6), 435–438. https://doi.org/10.3103/s1063457618060102

- Skripchenko, N., Tkachuk, М., Nedilko, K., Kyrychuk, D, Borysenko, S., Kasai, O. (2016). Contact interaction of complex-shaped details with local compliance of the surface layer. Bulletin of NTU "KhPI". Series: Engineering and CAD, 39 (1211), 93–101. Available at: https://repository.kpi.kharkov.ua/server/api/core/bitstreams/a6ff27d4-67bc-4980-a387-bce9abed66e6/content

- Properties and Selection: Irons, Steels, and High-Performance Alloys (1990). ASM Handbook. https://doi.org/10.31399/asm.hb.v01.9781627081610

- AISI 347 Stainless Steel Datasheet. Ferrobend.

- Schober, P., Boer, C., Schwarte, L. A. (2018). Correlation Coefficients: Appropriate Use and Interpretation. Anesthesia & Analgesia, 126 (5), 1763–1768. https://doi.org/10.1213/ane.0000000000002864

##submission.downloads##

Опубліковано

Як цитувати

Номер

Розділ

Ліцензія

Авторське право (c) 2025 Petro Kyrychok, Dmytro Paliukh

Ця робота ліцензується відповідно до Creative Commons Attribution 4.0 International License.

Закріплення та умови передачі авторських прав (ідентифікація авторства) здійснюється у Ліцензійному договорі. Зокрема, автори залишають за собою право на авторство свого рукопису та передають журналу право першої публікації цієї роботи на умовах ліцензії Creative Commons CC BY. При цьому вони мають право укладати самостійно додаткові угоди, що стосуються неексклюзивного поширення роботи у тому вигляді, в якому вона була опублікована цим журналом, але за умови збереження посилання на першу публікацію статті в цьому журналі.

Ліцензійний договір – це документ, в якому автор гарантує, що володіє усіма авторськими правами на твір (рукопис, статтю, тощо).

Автори, підписуючи Ліцензійний договір з ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР», мають усі права на подальше використання свого твору за умови посилання на наше видання, в якому твір опублікований. Відповідно до умов Ліцензійного договору, Видавець ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР» не забирає ваші авторські права та отримує від авторів дозвіл на використання та розповсюдження публікації через світові наукові ресурси (власні електронні ресурси, наукометричні бази даних, репозитарії, бібліотеки тощо).

За відсутності підписаного Ліцензійного договору або за відсутністю вказаних в цьому договорі ідентифікаторів, що дають змогу ідентифікувати особу автора, редакція не має права працювати з рукописом.

Важливо пам’ятати, що існує і інший тип угоди між авторами та видавцями – коли авторські права передаються від авторів до видавця. В такому разі автори втрачають права власності на свій твір та не можуть його використовувати в будь-який спосіб.