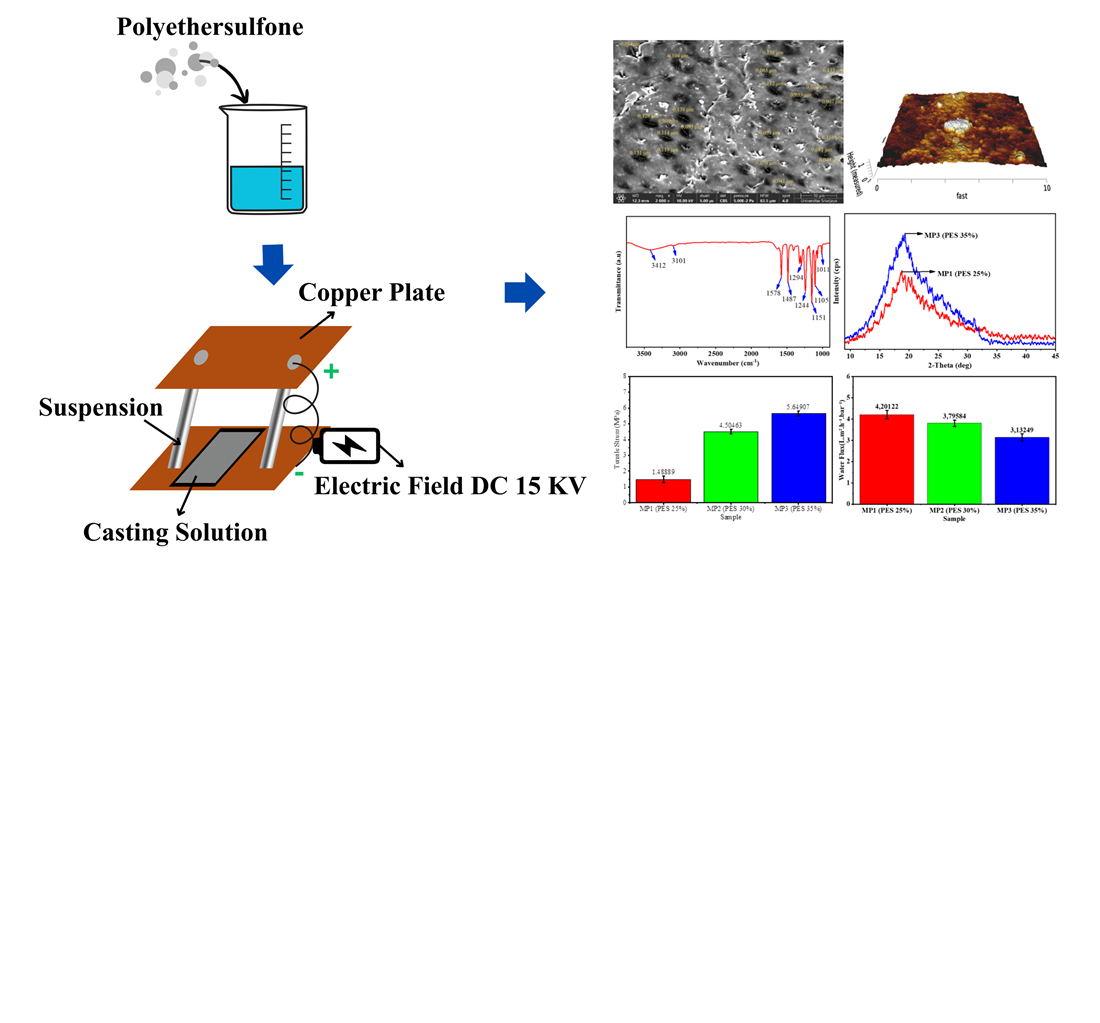

Identifying the features of mechanical and physicochemical characteristics of polyethersulfone membranes using electric field method for water filtration applications

DOI:

https://doi.org/10.15587/1729-4061.2025.339703Keywords:

chemical resistance, electric field, mechanical properties, physicochemical characteristics, water filtrationAbstract

Electric-field assistant prepared polyethersulfone (PES) membranes were selected as the research object in this paper, aiming to address how to control membrane morphology, mechanical property and water permeation at the same time through a simple and environmentally friendly method for filtration purposes. Three PES membranes were fabricated and denoted as MP1 (25% PES), MP2 (30% PES) and MP3 (35% PES). Results indicated that the electric field can be used as a feasible method to design desired membrane structure and performance, SEM observations shows average pore sizes of 0.062–0.095 μm, AFM images showed MP1 has rough surface with larger pores, and MP3 has smoother surface with finer pores. Tensile test results as well indicated that the mechanical properties of MP were evidently reinforced when adding PES, and all tensile strengths increased monotonous with increase in the concentration of PES, wherein MP3 had the best maximum tensile strength (5.64907407 MPa). FTIR spectra were in agreement with characteristic PES functional groups, XRD showed an overall amorphous nature and some semi-crystalline order developed that was predominantly exerted along the vertical direction to the support surface with concentration within PES-rich membranes. These findings account for the reported compromise of the filtration performance, MP1 presented in NWP with best permeability (4.2012164.L.m⁻2·h⁻1). bar⁻1; MP3 had better mechanical stability to the detriment of flux. All tests results demonstrated how membranes can be tailored to maximize either permeability (MP1) or mechanical strength and selectivity (MP3), thereby allowing them to be employed as direct water filtration materials and could be utilized as a support for advanced composite membrane systems.

References

- Sriyanti, I., Dani, R., Almafie, M. R., Partan, R. U., Ap Idjan, M. K. N., Marlina, L. (2024). Optimization of diameter and mechanical properties of Polyacrylonitrile/ Polyvinylidene fluoride/ Graphene oxide coconut shell composite nanofiber mats with using response surface methodology. Case Studies in Chemical and Environmental Engineering, 10, 101030. https://doi.org/10.1016/j.cscee.2024.101030

- Sriyanti, I., Almafie, M. R., Nuha Ap Idjan, M. K., Dani, R., Solihah, I., Syafri, E. et al. (2025). Electrospun nanofiber membrane of Piper beetle loaded PVDF/PAN for medical mask applications: psychochemical characteristics, antibacterial and air filter test. Advanced Membranes, 5, 100149. https://doi.org/10.1016/j.advmem.2025.100149

- Idjan, M. K. N. A., Fatmawati, Almafie, M. R., Dani, R., Subandrate, Fudholi, A., Sriyanti, I. (2025). Physicochemical properties and antioxidant activity of PVP/CA membranes nanofiber loaded Arcangelisia flava L. Merr. stem extract using electrospinning technique. Next Materials, 8, 100839. https://doi.org/10.1016/j.nxmate.2025.100839

- Almafie, M. R., Fudholi, A., Dani, R., Idjan, M. K. N. A., Royani, I., Sriyanti, I. (2025). Effects of electrospinning parameters on polycaprolactone membrane diameter: An investigation utilizing central composite design and characterization. Results in Engineering, 25, 104002. https://doi.org/10.1016/j.rineng.2025.104002

- Jauhari, J., Almafie, M. R., Annisa, M., Mataram, A., Marlina, L., Idjan, M. K. N. A., Sriyanti, I. (2021). The morphology and scaling law model of polyvinylidene fluoride/carbon fiber using electrospinning technique. Journal of Physics: Conference Series, 1796 (1), 012076. https://doi.org/10.1088/1742-6596/1796/1/012076

- Mataram, A., Firdaus, A., Yanis, M., Dani, R., Nasir, S., Ismail, A. F., Othman, M. H. D. (2024). Synthesis of polyethersulfone/titanium dioxide membranes: analysis of morphology, mechanical properties, and water filtration performance. Eastern-European Journal of Enterprise Technologies, 6 (6 (132)), 16–25. https://doi.org/10.15587/1729-4061.2024.316523

- Nasution, M. S., Mataram, A., Yani, I., Septano, G. D. (2022). Characteristics of a PVDF–Tin Dioxide Membrane Assisted by Electric Field Treatment. Membranes, 12 (8), 772. https://doi.org/10.3390/membranes12080772

- Firdaus, A., Nasir, S., Dani, R., Prasatya, I. N., Ismail, A. F., Othman, M. H. D., Mataram, A. (2024). Synthesis of polyethersulfone membranes with the addition of silver nitrate for water filter applications. EUREKA: Physics and Engineering, 1, 121–131. https://doi.org/10.21303/2461-4262.2025.003394

- Ngoma, M. M., Mathaba, M., Moothi, K. (2021). Effect of carbon nanotubes loading and pressure on the performance of a polyethersulfone (PES)/carbon nanotubes (CNT) membrane. Scientific Reports, 11 (1). https://doi.org/10.1038/s41598-021-03042-z

- Malatjie, K. I., Moutloali, R. M., Mishra, A. K., Mishra, S. B., Nxumalo, E. N. (2024). Photodegradation of imidacloprid insecticide using polyethersulfone membranes modified with iron doped cerium oxide. Journal of Applied Polymer Science, 141 (16). https://doi.org/10.1002/app.55255

- Barzegar, H., Shahsavarifar, S., Vatanpour, V., Masteri‐Farahani, M. (2021). Peroxopolyoxometalate nanoparticles blended PES membrane with improved hydrophilicity, anti‐fouling, permeability, and dye separation properties. Journal of Applied Polymer Science, 138 (31). https://doi.org/10.1002/app.50764

- Machodi, M. J., Daramola, M. O. (2020). Synthesis of PES and PES/chitosan membranes for synthetic acid mine drainage treatment. Water SA, 46 (1). https://doi.org/10.17159/wsa/2020.v46.i1.7891

- Ashori, A., Rafieyan, F., Kian, F., Jonoobi, M., Rezaei Tavabe, K. (2018). Effect of cellulose nanocrystals on performance of polyethersulfone nanocomposite membranes using electrospinning technique. Polymer Composites, 40 (S1). https://doi.org/10.1002/pc.25046

- Gohari, B., Abu-Zahra, N. (2018). Polyethersulfone Membranes Prepared with 3-Aminopropyltriethoxysilane Modified Alumina Nanoparticles for Cu(II) Removal from Water. ACS Omega, 3 (8), 10154–10162. https://doi.org/10.1021/acsomega.8b01024

- Elsayed, R., Teow, Y. H. (2024). Advanced functional polymer materials for biomedical applications. Journal of Applied Polymer Science, 142 (3). https://doi.org/10.1002/app.56391

- Rothermund, M. A., Koehler, S. J., Vaissier Welborn, V. (2024). Electric Fields in Polymeric Systems. Chemical Reviews, 124 (23), 13331–13369. https://doi.org/10.1021/acs.chemrev.4c00490

- Zhang, M., Hadi, M. K., Guo, D., Yao, T., Ran, F. (2024). Polyethersulfone mixed matrix membrane with abundant sponge pores for high‐separation performance with high flux retention and cycling stability. Journal of Applied Polymer Science, 141 (38). https://doi.org/10.1002/app.55979

- Grylewicz, A., Szymański, K., Darowna, D., Mozia, S. (2021). Influence of Polymer Solvents on the Properties of Halloysite-Modified Polyethersulfone Membranes Prepared by Wet Phase Inversion. Molecules, 26 (9), 2768. https://doi.org/10.3390/molecules26092768

- Sałacińska, A., Sienkiewicz, P., Szymański, K., Mozia, S. (2024). Polyethersulfone mixed matrix membranes modified with pore formers and Ag-titanate nanotubes: physicochemical characteristics and (bio)fouling study. Environmental Science and Pollution Research, 31 (55), 63876–63894. https://doi.org/10.1007/s11356-024-35461-6

- Ibrahim, Y., Hilal, N. (2024). Integration of Porous and Permeable Poly(ether sulfone) Feed Spacer onto Membrane Surfaces via Direct 3D Printing. ACS Applied Engineering Materials, 2 (4), 1094–1109. https://doi.org/10.1021/acsaenm.4c00086

- Huang, J., Tang, J., Zhang, J., Yang, L., Zhang, M. (2024). Waste mask supported PES membranes for efficient separation of oil/water emulsion. Polymer Engineering & Science, 64 (8), 3522–3529. https://doi.org/10.1002/pen.26777

- Butt, A. S., Qaiser, A. A., Abid, N., Mahmood, U. (2022). Novel polyaniline–polyethersulfone nanofiltration membranes: effect of in situ polymerization time on structure and desalination performance. RSC Advances, 12 (52), 33889–33898. https://doi.org/10.1039/d2ra05735b

- Güneş-Durak, S., Acarer-Arat, S., Tüfekci, M., Pir, İ., Üstkaya, Z., Öz, N., Tüfekci, N. (2024). Mechanical Enhancement and Water Treatment Efficiency of Nanocomposite PES Membranes: A Study on Akçay Dam Water Filtration Application. ACS Omega, 9 (29), 31556–31568. https://doi.org/10.1021/acsomega.4c01410

- Aumeier, B. M., Vollmer, F., Lenfers, S., Yüce, S., Wessling, M. (2021). Polymeric Membranes With Sufficient Thermo‐Mechanical Stability to Deploy Temperature Enhanced Backwash. Chemie Ingenieur Technik, 93 (9), 1417–1422. https://doi.org/10.1002/cite.202100020

- Matebese, F., Malomane, N., Motloutsi, M. L., Moutloali, R. M., Managa, M. (2025). Porphyrin-Modified Polyethersulfone Ultrafiltration Membranes for Enhanced Bacterial Inactivation and Filtration Performance. Membranes, 15 (8), 239. https://doi.org/10.3390/membranes15080239

- Khoerunnisa, F., Sihombing, M., Nurhayati, M., Dara, F., Triadi, H. A., Nasir, M. et al. (2022). Poly(ether sulfone)-based ultrafiltration membranes using chitosan/ammonium chloride to enhance permeability and antifouling properties. Polymer Journal, 54 (4), 525–537. https://doi.org/10.1038/s41428-021-00607-7

- Meng, N., Mi, J., Chen, X., Liu, J., Zhu, H., Zheng, X. (2025). Preparation of Highly Antibacterial Polyethersulfone/Sulfonated Polyethersulfone Blend Composite Membrane and Research on Its Dye Separation Performance. Molecules, 30 (4), 781. https://doi.org/10.3390/molecules30040781

- Abu-Zurayk, R., Alnairat, N., Waleed, H., Khalaf, A., Abu-Dalo, D., Bozeya, A., Afaneh, R. (2025). Dual-Mode Integration of a Composite Nanoparticle in PES Membranes: Enhanced Performance and Photocatalytic Potential. Nanomaterials, 15 (14), 1055. https://doi.org/10.3390/nano15141055

- Ambarita, A. C., Mulyati, S., Arahman, N., Bilad, M. R., Shamsuddin, N., Ismail, N. M. (2021). Improvement of Properties and Performances of Polyethersulfone Ultrafiltration Membrane by Blending with Bio-Based Dragonbloodin Resin. Polymers, 13 (24), 4436. https://doi.org/10.3390/polym13244436

- Dani, R., Ismet, I., Marlina, L., Alisya, R., Aldi, M. A. K., Ludiansyah, A. et al. (2024). Synthesis of Activated Carbon from Coconut Shell and Recycled Styrofoam Nanofiber for Water Filtration. Makara Journal of Science, 28 (4), 357–369. https://doi.org/10.7454/mss.v28i4.2284

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Aneka Firdaus, Rahma Dani, Muhammad Satya Putra Gantada, Ahmad Fauzi Ismail, Nukman Nukman, Irwin Bizzy, Agung Mataram

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.