Cleaning-in-place station decomposition for object-oriented control

DOI:

https://doi.org/10.15587/1729-4061.2025.343204Keywords:

Abstract

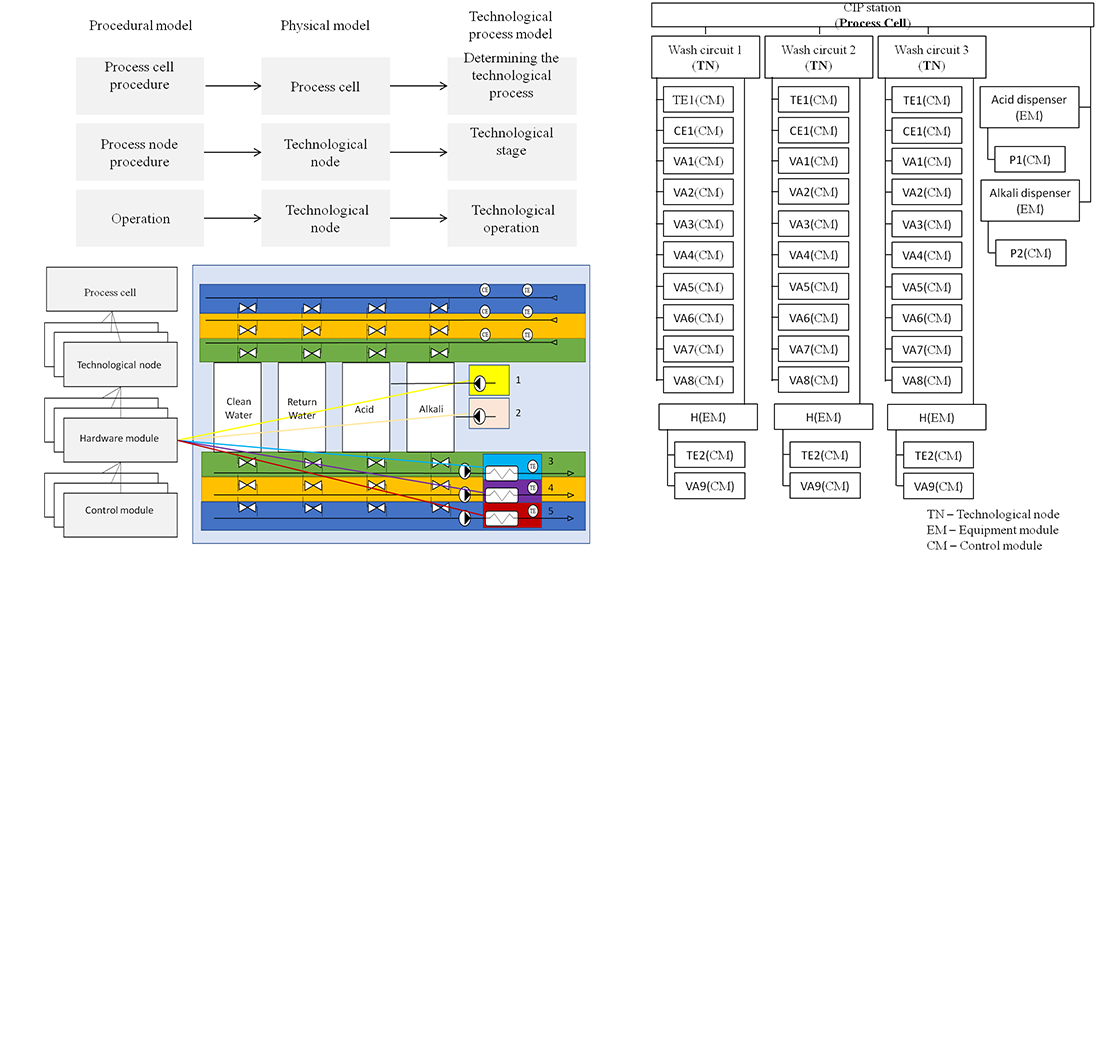

This study considers a CIP station used for automated cleaning of process equipment in the food industry. The task addressed relates to the lack of a formalized methodology for decomposing a CIP station that would enable the construction of object-oriented control models in accordance with international standards.

The result of this study is the devised methodology for CIP station decomposition based on the principles of IEC 61512, which includes the identification of the levels of process cell, process units, equipment modules, as well as control modules. It has been shown that this approach allows for a structured representation of the equipment and its functions, enabling the integration of technological steps with the equipment of the CIP station.

The results are attributed to the fact that the CIP cleaning process has a hierarchical structure and procedural repeatability, which allows it to be formalized as a set of interrelated levels – from the process cell to individual equipment modules. This feature ensures consistency between the process logic and the physical structure of the equipment, which enhances the efficiency of control. A distinctive feature of the results is the combination of hardware hierarchy with information models, which differentiates the proposed solution from conventional descriptive approaches. This not only improves the flexibility and scalability of control systems but also creates conditions for building libraries of reusable software objects.

The results could be practically implemented at industrial enterprises in the food, pharmaceutical, and chemical industries where CIP stations are used. They could be integrated into current SCADA/PLC systems using AutomationML and OPC UA standards, ensuring compatibility with MES/ERP levels of control. This improves the efficiency of equipment operation while reducing the costs for designing and maintaining automation systems

References

- Memisi, N., Moracanin, S. V., Milijasevic, M., Babic, J., Djukic, D. (2015). CIP Cleaning Processes in the Dairy Industry. Procedia Food Science, 5, 184–186. https://doi.org/10.1016/j.profoo.2015.09.052

- Jin, G., Jiang, Z., Sun, Y., Liu, Z., Liu, S., Wu, F. (2025). Intelligent clean-in-place (CIP) system in beverage (healthy water) cleaner production. Food Control, 168, 110877. https://doi.org/10.1016/j.foodcont.2024.110877

- Belei, O., Shtaier, L., Stasіuk, R., Mirzojeva, A. (2023). Design of the human-machine interface for the cleaning-in-place system in the dairy industry. Eastern-European Journal of Enterprise Technologies, 3 (2 (123)), 44–51. https://doi.org/10.15587/1729-4061.2023.282695

- Obermeier, M., Braun, S., Vogel-Heuser, B. (2015). A Model-Driven Approach on Object-Oriented PLC Programming for Manufacturing Systems with Regard to Usability. IEEE Transactions on Industrial Informatics, 11 (3), 790–800. https://doi.org/10.1109/tii.2014.2346133

- Pupena, О., Elperin, I., Mirkevych, R. (2017). Modern standards of integrated management and ways of their implementation in Ukraine. Scientific Works of NUFT, 23 (1), 25–41. Available at: https://elibrary.nuft.edu.ua/library/DocDescription?doc_id=355445

- Рupena, A., Elperin, I., Mirkevich, R., Klymenko, O. (2017). Computer integrated manufacturing: overview of modern standards. Automation of Technological and Business Processes, 8 (3), 63–74. https://doi.org/10.15673/atbp.v8i3.571

- Stenger, F., Schmalz, D., Bieringer, T., Brodhagen, A., Dreiser, C., Schweiger, A. (2016). Flexible Chemical Production by Modularization and Standardization: Status Quo and Future Trends. Chemie Ingenieur Technik, 88 (9), 1217–1217. https://doi.org/10.1002/cite.201650240

- Parant, A., Gellot, F., Zander, D., Carré-Ménétrier, V., Philippot, A. (2023). Model-based engineering for designing cyber-physical systems from product specifications. Computers in Industry, 145, 103808. https://doi.org/10.1016/j.compind.2022.103808

- Busboom, A. (2024). Automated generation of OPC UA information models – A review and outlook. Journal of Industrial Information Integration, 39, 100602. https://doi.org/10.1016/j.jii.2024.100602

- Henßen, R., Schleipen, M. (2014). Interoperability between OPC UA and AutomationML. Procedia CIRP, 25, 297–304. https://doi.org/10.1016/j.procir.2014.10.042

- IEC 61512-1: BATCH Control Part 1: Models and Terminology (2013). International Electrotechnical Commission. Available at: https://interoperable-europe.ec.europa.eu/collection/ict-standards-procurement/solution/iec-61512-11997-batch-control-part-1-models-and-terminology/distribution/iec-61512-11997-batch-control-part-1-models-and-terminology

- Méndez, C. A., Cerdá, J., Grossmann, I. E., Harjunkoski, I., Fahl, M. (2006). State-of-the-art review of optimization methods for short-term scheduling of batch processes. Computers & Chemical Engineering, 30 (6-7), 913–946. https://doi.org/10.1016/j.compchemeng.2006.02.008

- Alvarado, J., Vegetti, M., Gonnet, S. (2025). Asset Administration Shell Submodel for Representing the Procedural Part of ISA-88 Recipes. IEEE Latin America Transactions, 23 (1), 36–42. https://doi.org/10.1109/tla.2025.10810401

- Garcia, A., Oregui, X., Arrieta, U., Valverde, I. (2022). Methodology and Tools to Integrate Industry 4.0 CPS into Process Design and Management: ISA-88 Use Case. Information, 13 (5), 226. https://doi.org/10.3390/info13050226

- Munoz, E., Capon-Garcia, E., Puigjaner, L. (2017). ANSI/ISA 88-95 Standards Based-Approach for Improved Integration of Recipes and Operational Tasks Supported by Knowledge Management. 27th European Symposium on Computer Aided Process Engineering, 2335–2340. https://doi.org/10.1016/b978-0-444-63965-3.50391-3

- Unver, H. O. (2012). An ISA-95-based manufacturing intelligence system in support of lean initiatives. The International Journal of Advanced Manufacturing Technology, 65 (5-8), 853–866. https://doi.org/10.1007/s00170-012-4223-z

- De Minicis, M., Giordano, F., Poli, F., Schiraldi, M. M. (2014). Recipe Development Process Re-Design with ANSI/ISA-88 Batch Control Standard in the Pharmaceutical Industry. International Journal of Engineering Business Management, 6. https://doi.org/10.5772/59025

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Volodymyr Polupan, Oleksandr Pupena, Roman Mirkevych, Oleh Klymenko, Oleksii Mirkevych

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.