Revealing the influence of 3D printing density on the physical and mechanical properties of polymer articles

DOI:

https://doi.org/10.15587/1729-4061.2025.343939Keywords:

3D printing density, PETG, Ludwick’s power function, nonlinear stress-strain dependenceAbstract

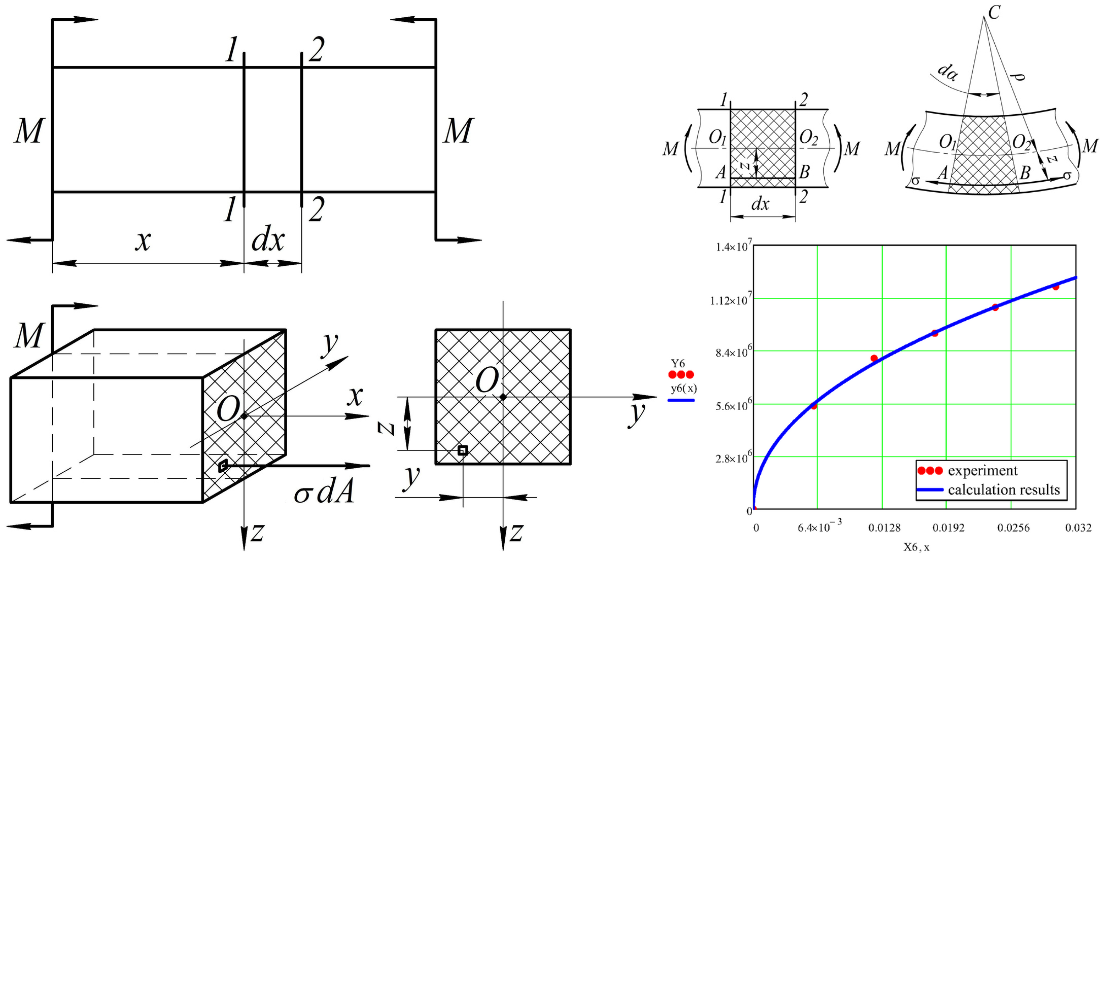

This study investigates the process of 3D printing of polymer articles in light industry. The task addressed is to determine the stressed-strained state of 3D-printed articles made of PETG polymer, taking into account the nonlinear (inelastic) physical and mechanical properties of the material and the influence of printing density on its mechanical behavior.

The study’s result established that the tensile curve of 3D-printed samples from PETG follows the form of power function that reflects the properties of an inelastic polymer material. Applying the resulting power function relationship between deformations and stress, unlike the linear one, has made it possible to determine the normal stresses that appear in the internal layers of 3D-printed articles in the form of a beam of rectangular cross-section at bending.

Numerical values were derived for parameters of the power function that reflects the dependence of stresses on strain when stretching 3D-printed samples from PETG, manufactured at a print density of 70%, 80%, 90%, and 100%. It was found that with an increase in the density of PETG 3D printing from 60% to 100%, the tensile stresses in the samples increase from 12.3 to 19.6 MPa, while the relative deformation at their rupture decreases from 0.076 to 0.062. The resulting dependences make it possible to determine the required density of 3D printing to ensure the predefined limit load parameters for articles during their application.

Taking into account the nonlinear nature of deformation and the influence of the density of the structure on tensile stresses and relative deformation at the rupture of the polymer material creates opportunities for designing and manufacturing 3D-printed articles in light industry with predictable properties to enable their operability under operational loads.

References

- Zhang, J., Lu, S., Yang, Y., Liu, Y., Guo, Y., Wang, H. (2024). Efficacy of auxetic lattice structured shoe sole in advancing footwear comfort – From the perspective of plantar pressure and contact area. Frontiers in Public Health, 12. https://doi.org/10.3389/fpubh.2024.1412518

- Leshchyshyn, M., Zlotenko, B., Synyuk, O., Kuleshova, S., Onofriichuk, V., Mykhailovskyi, Y. (2023). 3D printing of pads on lasts utilized in the production of custom-made comfortable footwear. Leather and Footwear Journal, 23 (4), 231–240. Available at: https://www.revistapielarieincaltaminte.ro/revistapielarieincaltaminteresurse/en/fisiere/full/vol23-nr4/article1_vol23_issue4.pdf

- Li, J., Jung, I., Lee, S. (2025). Analysis of midsole gait in running shoes with various 3D printed biomimetic structure. Scientific Reports, 15 (1). https://doi.org/10.1038/s41598-025-92235-x

- Li, J., Jung, I., Lee, S. (2024). Analysis of plantar pressure of midsole prepared by 3D printed biomimetic structures with different densities. Fashion and Textiles, 11 (1). https://doi.org/10.1186/s40691-024-00402-x

- Philippart, W., Bus, S., van Dieën, J. H. (2022). The Effects of 3D-Printed Silicone Midsole Design on Gait Biomechanics. SSRN Electronic Journal. https://doi.org/10.2139/ssrn.4156115

- Fadeel, A., Abdulhadi, H., Newaz, G., Srinivasan, R., Mian, A. (2022). Computational investigation of the post-yielding behavior of 3D-printed polymer lattice structures. Journal of Computational Design and Engineering, 9 (1), 263–277. https://doi.org/10.1093/jcde/qwac001

- Baranowski, P., Kapusta, A., Płatek, P., Sarzyński, M. (2024). Influence of 3D-printed cellular shoe soles on plantar pressure during running − Experimental and numerical studies. Biocybernetics and Biomedical Engineering, 44 (4), 858–873. https://doi.org/10.1016/j.bbe.2024.11.004

- Skyba, M., Synyuk, O., Zlotenko, B., Kulik, T., Natroshvili, S. (2021). A new modern theoretical view of the structural model of the structure of natural leather. Vlakna a Textil, 28 (2), 82–90. Available at: http://vat.ft.tul.cz/2021/2/VaT_2021_2_10.pdf

- Skyba, M. Ye., Synyuk, O. M., Zlotenko, B. M. (2019). Model of changing the stressed-deformed state of a polymer sheet during stretching. Naukovyi Visnyk Natsionalnoho Hirnychoho Universytetu, 1, 83–89. https://doi.org/10.29202/nvngu/2019-1/4

- Shin, D. S., Kim, Y. S., Jeon, E. S. (2019). Approximation of Non-Linear Stress–Strain Curve for GFRP Tensile Specimens by Inverse Method. Applied Sciences, 9 (17), 3474. https://doi.org/10.3390/app9173474

- Li, X., Zhang, X., Chen, J., Huang, L., Lv, Y. (2021). Uniaxial Tensile Creep Behavior of Epoxy-Based Polymer Using Molecular Simulation. Polymers, 13 (2), 261. https://doi.org/10.3390/polym13020261

- Kurkin, E., Spirina, M., Espinosa Barcenas, O. U., Kurkina, E. (2022). Calibration of the PA6 Short-Fiber Reinforced Material Model for 10% to 30% Carbon Mass Fraction Mechanical Characteristic Prediction. Polymers, 14 (9), 1781. https://doi.org/10.3390/polym14091781

- Erkkilä, A.-L., Leppänen, T., Hämäläinen, J. (2013). Empirical plasticity models applied for paper sheets having different anisotropy and dry solids content levels. International Journal of Solids and Structures, 50 (14-15), 2151–2179. https://doi.org/10.1016/j.ijsolstr.2013.03.004

- Palaparti, D. P. R., Choudhary, B. K., Isaac Samuel, E., Srinivasan, V. S., Mathew, M. D. (2012). Influence of strain rate and temperature on tensile stress–strain and work hardening behaviour of 9Cr–1Mo ferritic steel. Materials Science and Engineering: A, 538, 110–117. https://doi.org/10.1016/j.msea.2011.12.109

- Pysarenko, H. S., Kvitka, O. L., Umanskyi, E. S.; Pysarenko, H. S. (Ed.) (2004). Opir materialiv. Kyiv: Vyshcha shk., 655. Available at: https://btpm.nmu.org.ua/ua/download/%D0%9F%D0%B8%D1%81%D0%B0%D1%80%D0%B5%D0%BD%D0%BA%D0%BE%20%D0%93.%D0%A1.%20%D0%9E%D0%BF%D1%96%D1%80%20%D0%BC%D0%B0%D1%82%D0%B5%D1%80%D1%96%D0%B0%D0%BB%D1%96%D0%B2.pdf

- Zlotenko, B., Volianyk, O., Rubanka, M., Statsenko, D., Melnyk, H. (2025). Use of innovative computer tools and scientific research methods in the footwear industry. Herald of Khmelnytskyi National University. Technical Sciences, 351 (3.1), 382–388. https://doi.org/10.31891/2307-5732-2025-351-46

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Borys Zlotenko, Oleksii Volianyk, Mykola Rubanka, Dmytro Statsenko, Andrii Polishchuk, Oleksandr Duka

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.