Determining formation features of a wear-resistant layer surfaced with powder tape

DOI:

https://doi.org/10.15587/1729-4061.2025.346696Keywords:

powder tape, multilayer deposition, deposited metal, mathematical model, complex alloysAbstract

This study investigates the technological process of surfacing parts with a powder tape. The task addressed is to optimize the technological process of multilayer arc surfacing with powder tapes based on mathematical modeling of the formation of a seam of a given chemical composition with a minimum allowance for subsequent mechanical processing.

The technological parameters for the coating formation process have been calculated depending on the thickness of the surfacing layer of surfaces after machining, the maximum number of surfacing layers, and the required chemical composition of the weld metal. That has made it possible to devise technological recommendations for surfacing complex alloys on parts of a wide range of applications that operate under conditions of intensive wear.

The results are relevant in additive technologies, part of which is arc surfacing with powder electrodes of various designs, when it is necessary to fabricate an article by sequentially applying layers along a trajectory that repeats the geometry of the parts. The proposed mathematical models make it possible to obtain a reliable and operational assessment of the influence of technological process parameters on the formation of the chemical composition and geometry of the deposited layer during multilayer surfacing, taking into account the minimum waste of deposited metal after finishing grooving.

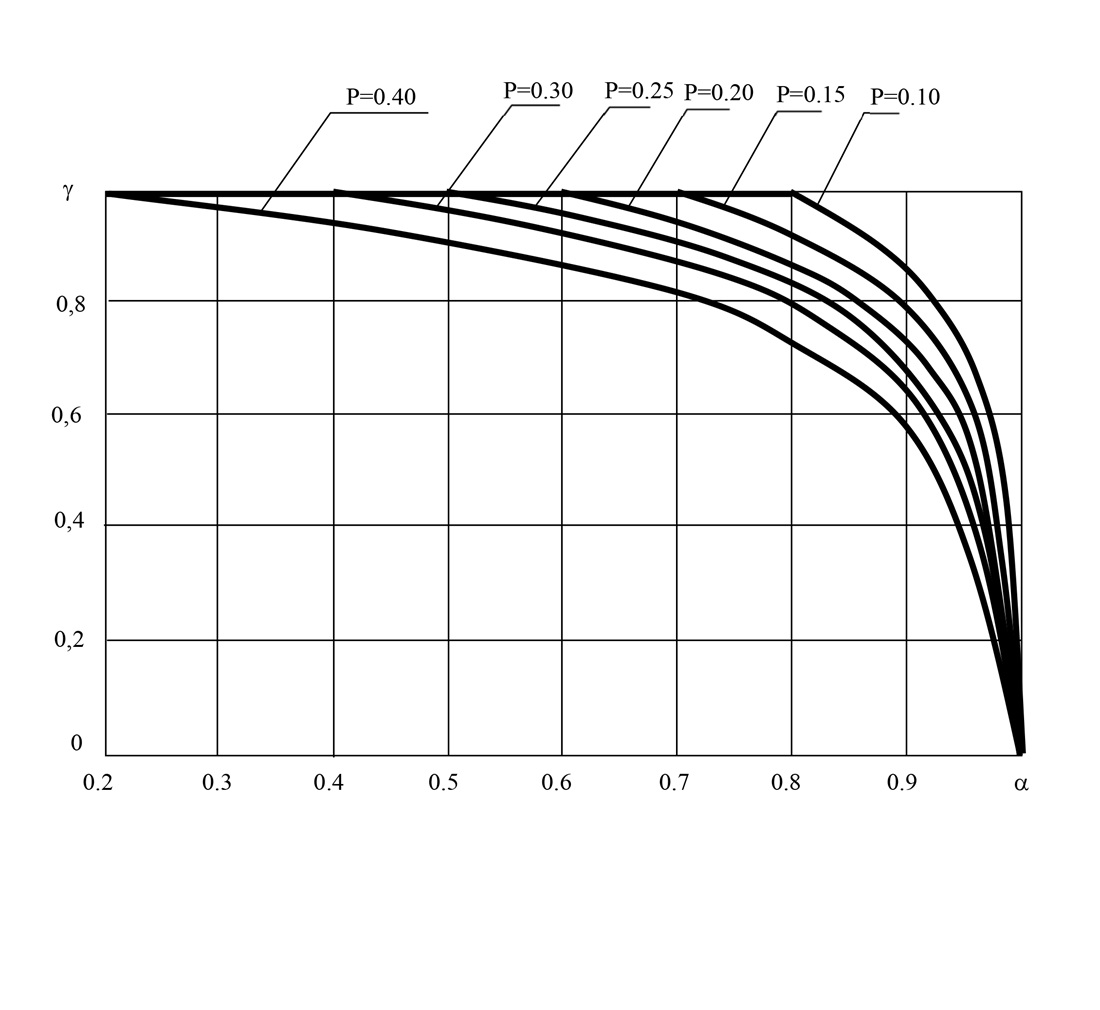

With values of the ratio of the height of the reinforcement roller to its width (≤ 0.3) and the relative surfacing step within 0.75–0.90, the maximum efficiency of the formation of a multilayer coating is ensured (by the minimum height of the deposited layer). It also enables the minimization of costs for subsequent machining, taking into account the imitation of errors (by the maximum height of irregularities). If the weld reinforcement coefficient is more than 2, then the required chemical composition is achieved already in the second coating layer.

The resulting numerical accuracy makes it possible to predict effective ways to save welding materials and reduce the labor intensity of the process when surfacing complex-alloyed wear-resistant alloys.

References

- Prysyazhnyuk, P., Ivanov, O., Matvienkiv, O., Marynenko, S., Korol, O., Koval, I. (2022). Impact and abrasion wear resistance of the hardfacings based on high-manganese steel reinforced with multicomponent carbides of Ti-Nb-Mo-V-C system. Procedia Structural Integrity, 36, 130–136. https://doi.org/10.1016/j.prostr.2022.01.014

- Voronchuk, O. P., Zhudra, O. P., Kaida, T. V., Petrov, O. V., Kapitanchuk, L. M., Bogaichuk, I. L. (2022). Influence of the composition of charge components of flux-cored strips of C–Fe–Cr–Nb alloying system on chemical composition and structure of the deposited metal. Automatic Welding, 8, 29–34. https://doi.org/10.37434/as2022.08.04

- Yang, X. (2015). Analysis of Chinese Welding Industries Today and in the Future (Focus on Cost, Productivity, and Quality). International Journal of Mechanical Engineering and Applications, 3 (6), 127. https://doi.org/10.11648/j.ijmea.20150306.15

- Quintino, L. (2014). Overview of coating technologies. Surface Modification by Solid State Processing, 1–24. https://doi.org/10.1533/9780857094698.1

- Gribkov, E. P., Perig, A. V. (2016). Research of energy-power parameters during powder wire flattening. The International Journal of Advanced Manufacturing Technology, 85 (9-12), 2887–2900. https://doi.org/10.1007/s00170-016-8714-1

- Trembach, B., Grin, A., Makarenko, N., Zharikov, S., Trembach, I., Markov, O. (2020). Influence of the core filler composition on the recovery of alloying elements during the self-shielded flux-cored arc welding. Journal of Materials Research and Technology, 9 (5), 10520–10528. https://doi.org/10.1016/j.jmrt.2020.07.052

- Kassov, V., Berezshna, O., Yermakova, S., Turchanin, D., Malyhina, S. (2025). Features of heating and melting of powder tape for surfacing of composite and complex-alloyed alloys. Eastern-European Journal of Enterprise Technologies, 2 (1 (134)), 60–67. https://doi.org/10.15587/1729-4061.2025.327904

- Gupta, D., Bansal, A., Jindal, S. (2024). Effect of fluxes in submerged arc welding for steel: A review. Materials Today: Proceedings. https://doi.org/10.1016/j.matpr.2024.05.053

- Suryakumar, S., Somashekara, M. A. (2013). Manufacturing of functionally gradient materials by using weld-deposition. Proceedings of the 1st International Joint Symposium on Joining and Welding, 505–508. https://doi.org/10.1533/978-1-78242-164-1.505

- Kavishwar, S., Bhaiswar, V., Kochhar, S., Fande, A. (2024). Comprehensive studies on conventional and novel weld cladding techniques and their variants for enhanced structural integrity: an overview. Welding International, 38 (9), 618–638. https://doi.org/10.1080/09507116.2024.2402285

- Murugan, N., Parmar, R. S. (1994). Effects of MIG process parameters on the geometry of the bead in the automatic surfacing of stainless steel. Journal of Materials Processing Technology, 41 (4), 381–398. https://doi.org/10.1016/0924-0136(94)90003-5

- Balasubramanian, K., Vikram, R., Sambath, S., Sowrirajan, M., Arunachalashiva, M., Abhijith, P. V., Deepak, D. (2023). Optimization of flux cored arc welding parameters to minimize the dilution percentage of AISI 316L stainless steel cladding on mild steel. International Journal on Interactive Design and Manufacturing (IJIDeM), 19 (1), 55–65. https://doi.org/10.1007/s12008-023-01487-2

- Buki, A. A. (1992). Calculating the chemical composition of deposited metal when welding with coated electrodes. Welding International, 6 (10), 818–820. https://doi.org/10.1080/09507119209548294

- Palani, P. K., Murugan, N. (2006). Development of mathematical models for prediction of weld bead geometry in cladding by flux cored arc welding. The International Journal of Advanced Manufacturing Technology, 30 (7-8), 669–676. https://doi.org/10.1007/s00170-005-0101-2

- Ryabtsev, I. O., Babinets, A. A., Lentyuhov, I. P. (2025). Control of the formation of metal structure surface with flux-cored wires. Materials Science. https://doi.org/10.1007/s11003-025-00885-z

- Voronchuk, A. P. (2014). Flux-cored strips for wear-resistant surfacing. The Paton Welding Journal, 6-7, 72–75. https://doi.org/10.15407/tpwj2014.06.14

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Valeriy Kassov, Olena Berezshna, Svitlana Yermakova, Svetlana Malyhina, Dmytro Turchanin

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.