Defining ways for improving automatic technological lines for shock freezing of food products

DOI:

https://doi.org/10.15587/1729-4061.2025.347796Keywords:

quick freezing, food products, automation of technological lines, improvement of automatic controlAbstract

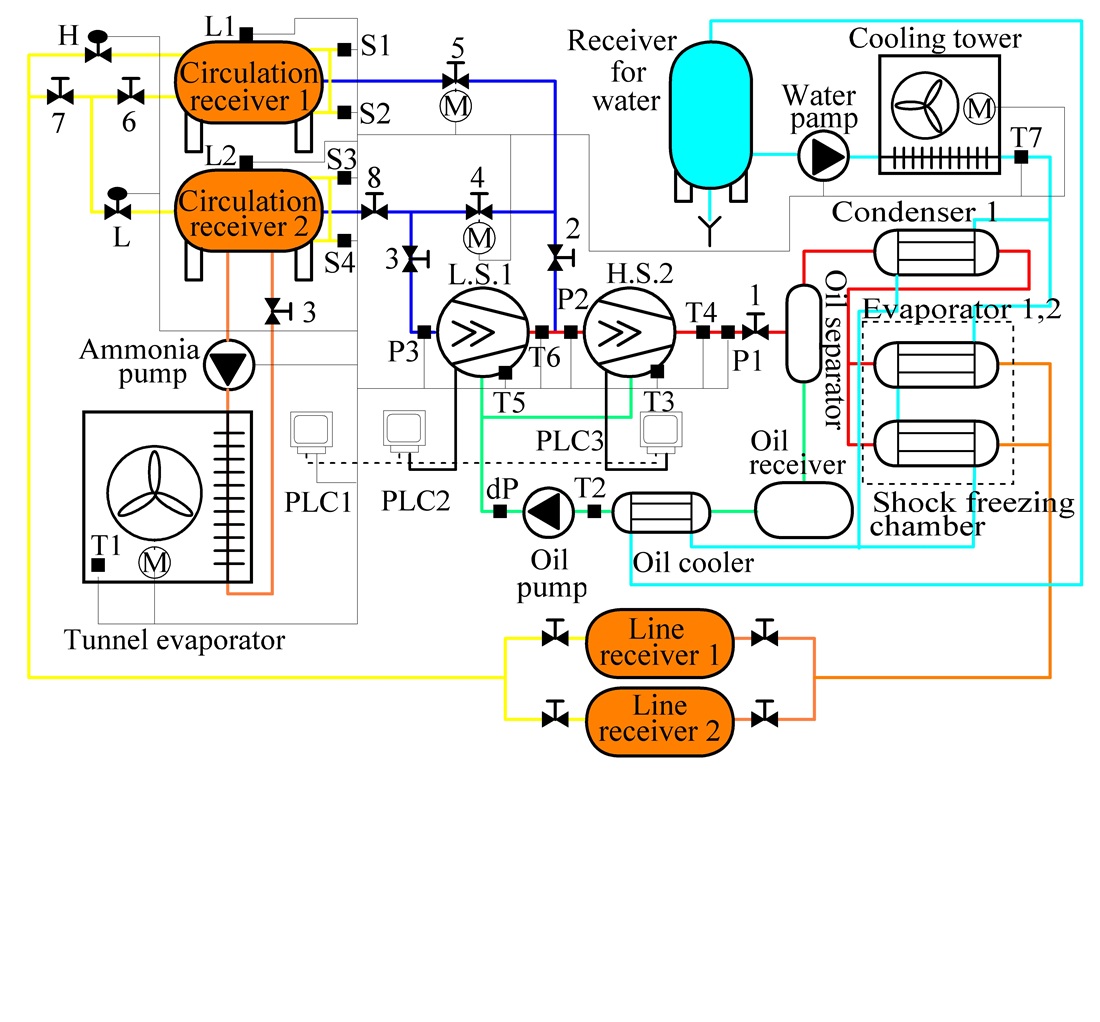

This study redesigns technological lines for dynamic shock freezing of food products with a long shelf life. The task is to reduce energy consumption per product unit and decrease the cost of maintaining technological lines.

It was established that replacing analog sensors of technological process parameters with digital devices makes it possible to shorten transition intervals between different operating modes of the line by more than 10 minutes. Applying controlled valves and gates in the equipment makes it possible to optimize automatic freezing modes, taking into account both the quality indicators of frozen products and the efficiency of equipment operation.

Modernization of equipment makes it possible to devise more effective automatic operation programs for shock freezing technological lines under the supervision of a single operator. This approach involves the selection of different automatic technological freezing modes for different products. In this case, product parameters (thermal conductivity, percentage of water content, dimensions of individual products) and the final state of frozen products (deep freezing to –30°C, quick freezing to –10°C, or others) are taken into account.

The service functions of the automatic control system in the technological line have been expanded. In particular, these include self-diagnosis, rapid automatic response to emergencies, automatic warning about refrigerant leakage, enhanced informativeness of the text-symbol display, as well as convenience of the operator-equipment interface. Experimental studies on the modernized automatic line have shown a reduction in electricity consumption by almost 50% while maintaining the capacity of cold generation

References

- Simakhina, G., Kaminska, S. (2020). The state and the perspectives of development of the domestic market of frozen fruit and berry half products. Scientific Works of National University of Food Technologies, 26 (3), 234–242. https://doi.org/10.24263/2225-2924-2020-26-3-26

- Ukraina zbilshyla obsiahy eksportu svizhykh i zamorozhenykh yahid u 2023 rotsi. Available at: https://uaexport.org/2024/04/01/ukrayina-zbilshila-obsyagi-eksportu-svizhih-i-zamorozhenih-yagid-u-2023-rotsi/

- Sutariya, S. G., Sunkesula, V. (2021). Food Freezing: Emerging Techniques for Improving Quality and Process Efficiency a Comprehensive Review. Innovative Food Processing Technologies, 36–63. https://doi.org/10.1016/b978-0-08-100596-5.23035-7

- Çalışkan Koç, G., Özkan Karabacak, A., Süfer, Ö., Adal, S., Çelebi, Y., Delikanlı Kıyak, B., Öztekin, S. (2025). Thawing frozen foods: A comparative review of traditional and innovative methods. Comprehensive Reviews in Food Science and Food Safety, 24 (2). https://doi.org/10.1111/1541-4337.70136

- Alsailawi, H. A., Mudhafar, M., Abdulrasool, M. M. (2020). Effect of frozen storage on the quality of frozen foods – a review. Journal of Chemistry and Chemical Engineering, 14, 86–96. https://doi.org/10.17265/1934-7375/2020.03.002

- James, C., Purnell, G., James, S. J. (2015). A Review of Novel and Innovative Food Freezing Technologies. Food and Bioprocess Technology, 8 (8), 1616–1634. https://doi.org/10.1007/s11947-015-1542-8

- Dhanya, R., Panoth Abhirami, Venkatachalapathy, N. (2024). A comprehensive review on isochoric freezing: a recent technology for preservation of food and non-food items. Sustainable Food Technology, 2 (1), 9–18. https://doi.org/10.1039/d3fb00146f

- Blast freezing is the best way to store fruit, vegetables, semi-finished products and ready meals. Available at: https://ralco.com.ua/en/articles/co-jest-zamrozenie-szoku-2/

- Cryogenic nitrogen in the food and beverage industry. Available at: https://iifiir.org/en/encyclopedia-of-refrigeration/cryogenic-nitrogen-in-the-food-and-beverage-industry

- Our product groups. EBG-electro. Available at: https://www.ebg-electro.com/en/products/

- Titlov, О., Hratii, T., Bilenko, N. (2020). Enhancing energy efficiency of absorption refrigeration devices. Refrigeration Engineering and Technology, 55 (5-6), 293–303. https://doi.org/10.15673/ret.v55i5-6.1659

- RS Americas. Available at: https://us.rs-online.com/

- The Global Catalog. Available at: https://store.danfoss.com/

- LOGO! – the compact controller with a cloud interface. Available at: https://www.siemens.com/global/en/products/automation/systems/industrial/plc/logo.html

- Ikram, A., Arshad, M. T., Maqsood, S., Safdar, S. Z., Rasheed, A., Ahmad, A. et al. (2025). Modern approaches for ensuring the safety and integrity of frozen foods: an overview. Food and Agricultural Immunology, 36 (1). https://doi.org/10.1080/09540105.2025.2491594

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Svitlana Вaloha, Serhiy Buletsa, Valentyn Ivanytsky, Viktor Kovtunenko, Jaroslav Legeta, Roman Meshko, Mykhaylo Ryaboshchuk

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.