The assessment of reflector material durability for concentrated solar power based on environment exposure and accelerated aging test

DOI:

https://doi.org/10.15587/1729-4061.2022.265678Keywords:

accelerated aging, concentrated solar power, reflector material, salt spray, soilingAbstract

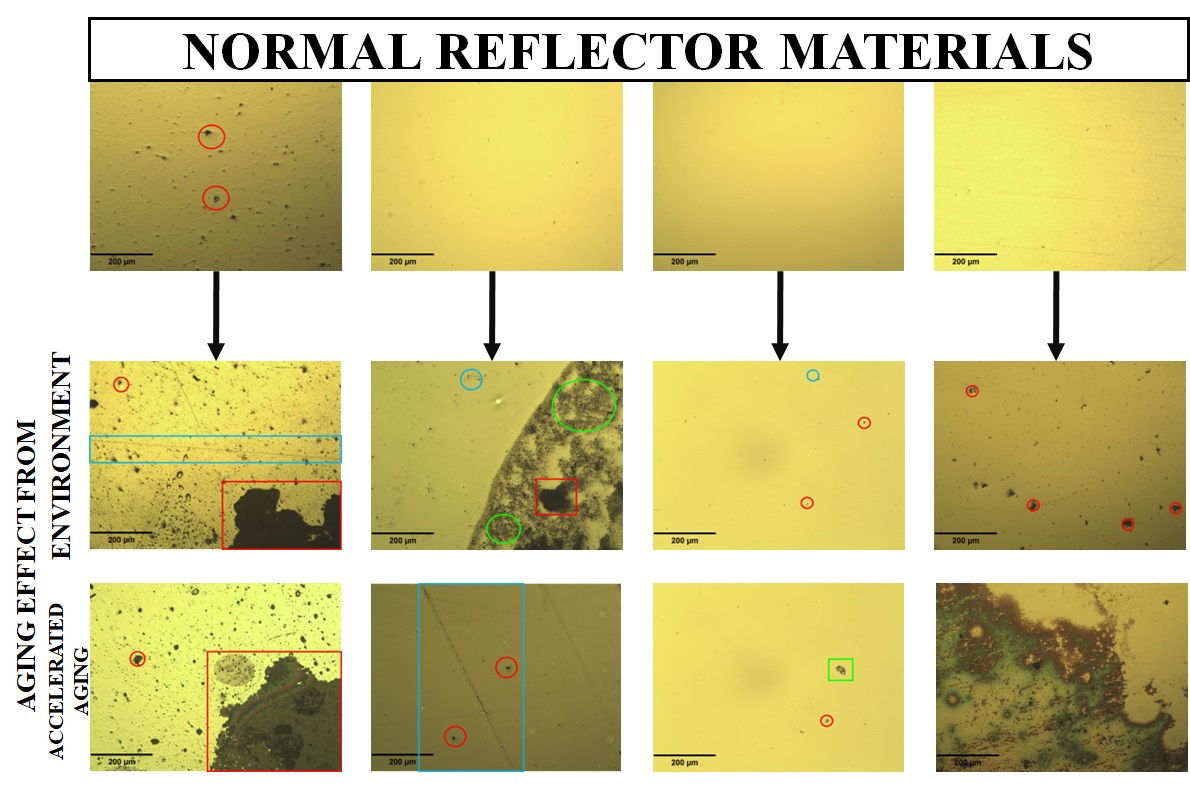

The reflector durability is essential to maintain suitable photo-to-thermal conversion in concentrated solar power plants. The present study evaluates the impact of environmental exposure and accelerated aging of the reflector material. The study is conducted to assess the reflector material's durability to withstand environmental exposure and accelerated aging test. The evaluation is conducted using four different reflector materials commonly used in concentrated solar power: stainless steel and silvered-glass mirror (solid-state reflector), aluminum and silvered-polymer film (sheet-based reflector). The environmental exposure and accelerated aging test are conducted for 1,080 hours according to the standard reference of ISO 8565:2011 and ASTM B117–11. The mass loss after exposure is used as a reference to determine the corrosion rate for each reflector. Further observation is conducted by using microscope light to observe the effect of exposure on the surface of the reflector. Each reflector indicates a different corrosion rate which implies different weather resistance for each reflector type. The highest corrosion rate is found on aluminum film, with a value of 295.8 g/m2.year. The accelerated aging test through neutral salt spray demonstrates that a metallic reflector has a higher corrosion rate compared to a silvered-glass mirror which uses silicon dioxide as the top coating. Microscope observation demonstrates that suitable protection from soiling elements for the silvered-glass mirror is mainly caused by the presence of silicon dioxide on the top surface of this reflector. The assessment suggests that a suitable coating can be developed to be used for reflector protection. Furthermore, the corrosion mechanism is observed clearly, which can be referred to the synthesis of new reflective material that withstands environment and salt exposure.

Supporting Agency

- The authors were grateful to Universitas Pancasila as being the funder of research under internal grant funding.

References

- Kozlov, I., Kovalchuk, V., Klymchuk, O., Dorozh, O., Sigal, A., Aksyonova, I., Elkin, Y. (2022). Assessing the Region'S Energy Provision. Eastern-European Journal of Enterprise Technologies, 2 (8 (116)), 13–20. doi: https://doi.org/10.15587/1729-4061.2022.255740

- Ismail, I., Mulyanto, A. T., Rahman, R. A. (2022). Development of free water knock-out tank by using internal heat exchanger for heavy crude oil. EUREKA: Physics and Engineering, 4, 77–85. doi: https://doi.org/10.21303/2461-4262.2022.002502

- Tsoy, A., Titlov, O., Granovskiy, A., Koretskiy, D., Vorobyova, O., Tsoy, D., Jamasheva, R. (2022). Improvement of refrigerating machine energy efficiency through radiative removal of condensation heat. Eastern-European Journal of Enterprise Technologies, 1 (8 (115)), 35–45. doi: https://doi.org/10.15587/1729-4061.2022.251834

- Petrivskyi, V., Shevchenko, V., Yevseiev, S., Milov, O., Laptiev, O., Bychkov, O. et al. (2022). Development of a modification of the method for constructing energy-efficient sensor networks using static and dynamic sensors. Eastern-European Journal of Enterprise Technologies, 1 (9 (115)), 15–23. doi: https://doi.org/10.15587/1729-4061.2022.252988

- Ismail, I., Rahman, R. A., Haryanto, G., Pane, E. A. (2021). The Optimal Pitch Distance for Maximizing the Power Ratio for Savonius Turbine on Inline Configuration. International Journal of Renewable Energy Research, 11 (2), 595–599. Available at: https://www.ijrer.org/ijrer/index.php/ijrer/article/view/11862/pdf

- Rahmalina, D., Rahman, R. A., Ismail. (2022). Increasing the rating performance of paraffin up to 5000 cycles for active latent heat storage by adding high-density polyethylene to form shape-stabilized phase change material. Journal of Energy Storage, 46, 103762. doi: https://doi.org/10.1016/j.est.2021.103762

- Wiyono, A., Saw, L. H., Anggrainy, R., Husen, A. S., Purnawan, Rohendi, D. et al. (2021). Enhancement of syngas production via co-gasification and renewable densified fuels (RDF) in an open-top downdraft gasifier: Case study of Indonesian waste. Case Studies in Thermal Engineering, 27, 101205. doi: https://doi.org/10.1016/j.csite.2021.101205

- Gandidi, I. M., Wiyono, A., Berman, E. T., Pambudi, N. A. (2019). Experimental upgrading of liquid crude oil obtained from calophyllum inophyllum by two-stage pyrolysis. Case Studies in Thermal Engineering, 16, 100544. doi: https://doi.org/10.1016/j.csite.2019.100544

- Mohamad, K., Ferrer, P. (2019). Parabolic trough efficiency gain through use of a cavity absorber with a hot mirror. Applied Energy, 238, 1250–1257. doi: https://doi.org/10.1016/j.apenergy.2019.01.163

- Rahman, R. A., Lahuri, A. H., Ismail, I. (2023). Thermal stress influence on the long-term performance of fast-charging paraffin-based thermal storage. Thermal Science and Engineering Progress, 37, 101546. doi: https://doi.org/10.1016/j.tsep.2022.101546

- Rahmalina, D., Adhitya, D. C., Rahman, R. A., Ismail, I. (2021). Improvement the performance of composite PCM paraffin-based incorporate with volcanic ash as heat storage for low-temperature application. EUREKA: Physics and Engineering, 1, 53–61. doi: https://doi.org/10.21303/2461-4262.2022.002055

- Adanta, D., Syofii, I., Sari, D., Wiyono, A. (2022). Performance of Pico Scale Turgo Turbine in Difference the Nozzle Diameter. International Journal of Fluid Machinery and Systems, 15 (1), 130–136. doi: https://doi.org/10.5293/ijfms.2022.15.1.130

- Fernández-García, A., Sutter, F., Fernández-Reche, J., Lüpfert, E. (2017). Mirrors. The Performance of Concentrated Solar Power (CSP) Systems, 67–98. doi: https://doi.org/10.1016/b978-0-08-100447-0.00003-1

- Zhu, G., Kearney, D., Mehos, M. (2014). On characterization and measurement of average solar field mirror reflectance in utility-scale concentrating solar power plants. Solar Energy, 99, 185–202. doi: https://doi.org/10.1016/j.solener.2013.11.009

- Asselineau, C.-A., Zapata, J., Pye, J. (2015). Integration of Monte-Carlo ray tracing with a stochastic optimisation method: application to the design of solar receiver geometry. Optics Express, 23 (11), A437. doi: https://doi.org/10.1364/oe.23.00a437

- Sutter, F., Montecchi, M., von Dahlen, H., Fernández-García, A., Röger, M. (2018). The effect of incidence angle on the reflectance of solar mirrors. Solar Energy Materials and Solar Cells, 176, 119–133. doi: https://doi.org/10.1016/j.solmat.2017.11.029

- Usmani, B., Dixit, A. (2016). Impact of corrosion on microstructure and mechanical properties of ZrOx/ZrC-ZrN/Zr absorber–reflector tandem solar selective structures. Solar Energy Materials and Solar Cells, 157, 733–741. doi: https://doi.org/10.1016/j.solmat.2016.07.019

- Sutter, F., Meyen, S., Fernández-García, A., Heller, P. (2016). Spectral characterization of specular reflectance of solar mirrors. Solar Energy Materials and Solar Cells, 145, 248–254. doi: https://doi.org/10.1016/j.solmat.2015.10.030

- Sutter, F., Fernández-García, A., Wette, J., Reche-Navarro, T. J., Martínez-Arcos, L. (2019). Acceptance criteria for accelerated aging testing of silvered-glass mirrors for concentrated solar power technologies. Solar Energy Materials and Solar Cells, 193, 361–371. doi: https://doi.org/10.1016/j.solmat.2019.01.008

- Sutter, F., Fernández-García, A., Wette, J., Wiesinger, F. (2017). Assessment of durability and accelerated aging methodology of solar reflectors. The Performance of Concentrated Solar Power (CSP) Systems, 169–201. doi: https://doi.org/10.1016/b978-0-08-100447-0.00006-7

- Azouzoute, A., Merrouni, A. A., Garoum, M., Bennouna, E. G. (2020). Soiling loss of solar glass and mirror samples in the region with arid climate. Energy Reports, 6, 693–698. doi: https://doi.org/10.1016/j.egyr.2019.09.051

- Wiesinger, F., Sutter, F., Fernández-García, A., Wette, J., Wolfertstetter, F., Hanrieder, N. et al. (2020). Sandstorm erosion on solar reflectors: Highly realistic modeling of artificial aging tests based on advanced site assessment. Applied Energy, 268, 114925. doi: https://doi.org/10.1016/j.apenergy.2020.114925

- Bellos, E., Tzivanidis, C. (2020). Solar concentrating systems and applications in Greece – A critical review. Journal of Cleaner Production, 272, 122855. doi: https://doi.org/10.1016/j.jclepro.2020.122855

- Wang, Y., Potter, D., Asselineau, C.-A., Corsi, C., Wagner, M., Caliot, C. et al. (2020). Verification of optical modelling of sunshape and surface slope error for concentrating solar power systems. Solar Energy, 195, 461–474. doi: https://doi.org/10.1016/j.solener.2019.11.035

- Sattler, J. C., Röger, M., Schwarzbözl, P., Buck, R., Macke, A., Raeder, C., Göttsche, J. (2020). Review of heliostat calibration and tracking control methods. Solar Energy, 207, 110–132. doi: https://doi.org/10.1016/j.solener.2020.06.030

- Hijazi, H., Mokhiamar, O., Elsamni, O. (2016). Mechanical design of a low cost parabolic solar dish concentrator. Alexandria Engineering Journal, 55 (1), 1–11. doi: https://doi.org/10.1016/j.aej.2016.01.028

- Dey, T., Naughton, D. (2019). Nano-porous sol-gel derived hydrophobic glass coating for increased light transmittance through greenhouse. Materials Research Bulletin, 116, 126–130. doi: https://doi.org/10.1016/j.materresbull.2019.04.027

- Kennedy, C. E., Terwilliger, K. (2005). Optical Durability of Candidate Solar Reflectors. Journal of Solar Energy Engineering, 127 (2), 262–269. doi: https://doi.org/10.1115/1.1861926

- Weinstein, L. A., Loomis, J., Bhatia, B., Bierman, D. M., Wang, E. N., Chen, G. (2015). Concentrating Solar Power. Chemical Reviews, 115 (23), 12797–12838. doi: https://doi.org/10.1021/acs.chemrev.5b00397

- Alex, S., Kumar P, R., Chattopadhyay, K., Barshilia, H. C., Basu, B. (2019). Thermally evaporated Cu–Al thin film coated flexible glass mirror for concentrated solar power applications. Materials Chemistry and Physics, 232, 221–228. doi: https://doi.org/10.1016/j.matchemphys.2019.04.078

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 Budhi Muliawan Suyitno, Reza Abdu Rahman, Hendri Sukma, Dwi Rahmalina

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.