Improvement of methods for description of a three-bunker collection conveyor

DOI:

https://doi.org/10.15587/1729-4061.2022.265770Keywords:

PiKh model, speed control, transport delay, accumulating bunker, similarity criteriaAbstract

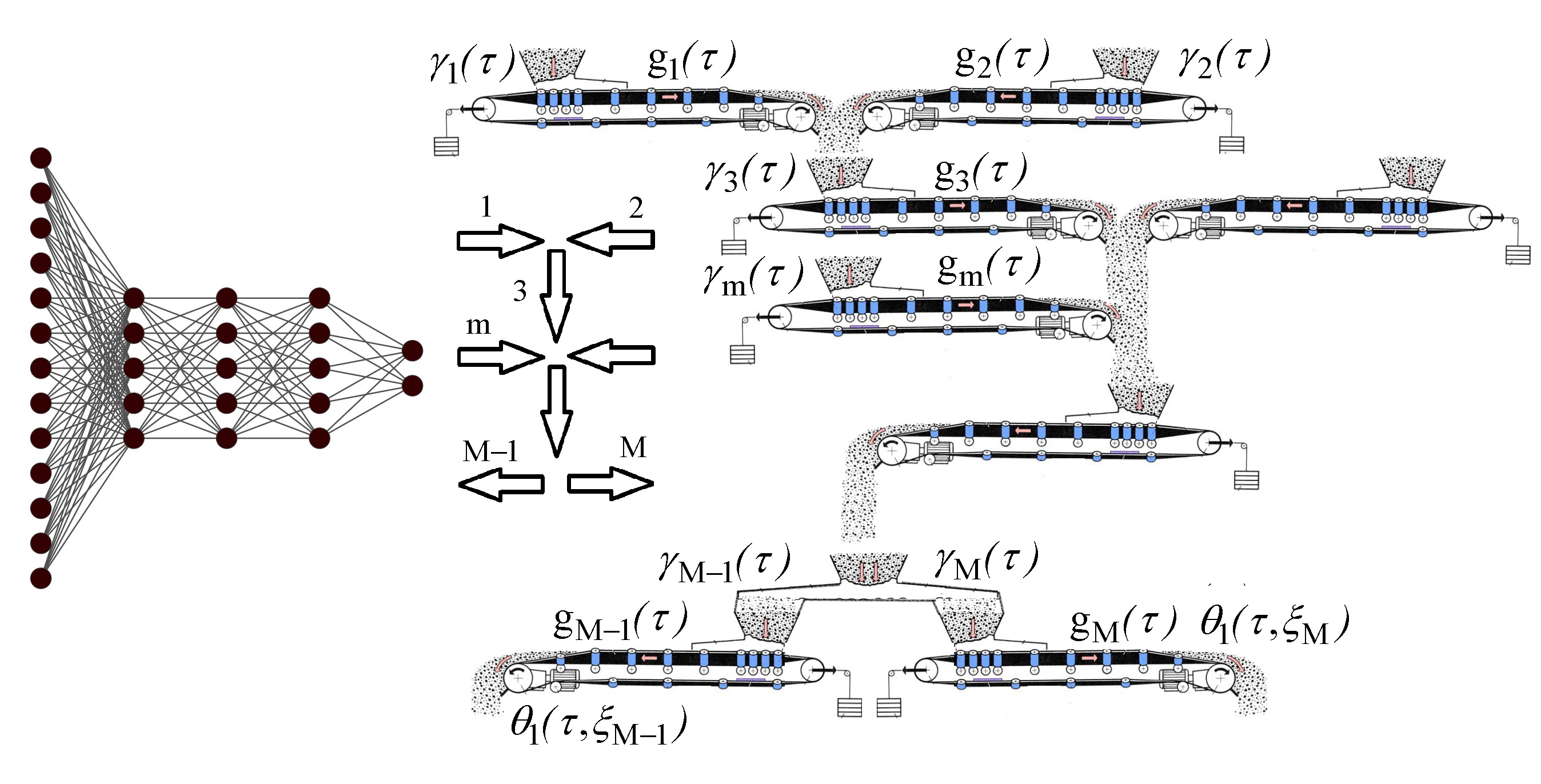

The object of current research is a multi-section transport conveyor. The actual control problem of the flow parameters of a multi-section conveyor-type transport system with a given control quality criterion is solved. Algorithms for optimal control of the flow of material coming from the input accumulating bunkers into the collection section of the conveyor, ensuring the filling of the accumulating tank in the minimum time were synthesized. An admissible control of the material flow from the accumulating bunkers is found, which allow filling the accumulating tank, taking into account the given distribution of the material along the section of the collection conveyor at the initial and final moments of the filling time with minimal energy consumption. The synthesis of algorithms for optimal control of the material flow from accumulating bunkers became possible due to the determination of differential constraints in the optimal control problem based on an analytical distributed model of a transport conveyor section. The distinctive features of the results obtained are that the allowable controls contain restrictions on the maximum allowable load of material on the conveyor belt and take into account the initial and final distribution of material along the collection conveyor section. Also, a feature of the obtained results is the consideration of variable transport delay in the transport conveyor control model. The application area of the results is the mining industry. The developed models make it possible to synthesize algorithms for optimal control of the flow parameters of the transport system for a mining enterprise, taking into account the transport delay in the incoming of material at the output of the conveyor section. The condition for the practical use of the results obtained is the presence of measuring sensors in the sections of the transport conveyor that determine the belt speed and the amount of material in the accumulating bunkers.

References

- Siemens – innovative solutions for the mining industry. Available at: https://im-mining.com/advertiser_profile/siemens-innovative-solutions-mining-industry/

- Pihnastyi, O., Ivanovska, O. (2022). Improving the prediction quality for a multi-section transport conveyor model based on a neural network. Proceedings of International Scientific Conference Information Technology and Implementation, 3132, 24–38. Available at: http://ceur-ws.org/Vol-3132/Paper_3.pdf

- Bajda, M., Błażej, R., Jurdziak, L. (2019). Analysis of changes in the length of belt sections and the number of splices in the belt loops on conveyors in an underground mine. Engineering Failure Analysis, 101, 436–446. doi: https://doi.org/10.1016/j.engfailanal.2019.04.003

- Koman, M., Laska, Z. (2014) The constructional solution of conveyor system for reverse and bifurcation of the ore flow. Rudna mine, 3 (72), 69–82.

- Jeftenic, B., Ristic, L., Bebic, M., Statkic, S., Mihailovic, I., Jevtic, D. (2010). Optimal utilization of the bulk material transportation system based on speed controlled drives. The XIX International Conference on Electrical Machines - ICEM 2010. doi: https://doi.org/10.1109/icelmach.2010.5608055

- Pihnastyi, O., Khodusov, V. (2020). Development of the controlling speed algorithm of the conveyor belt based on TOU-tariffs. Proceedings of the 2nd International Workshop on Information-Communication Technologies & Embedded Systems, 2762, 73–86. Available at: https://mpra.ub.uni-muenchen.de/104681/

- Halepoto, I. A., Shaikh, M. Z., Chowdhry, B. S., Uqaili, M. u hammad A. (2016). Design and Implementation of Intelligent Energy Efficient Conveyor System Model Based on Variable Speed Drive Control and Physical Modeling. International Journal of Control and Automation, 9 (6), 379–388. doi: https://doi.org/10.14257/ijca.2016.9.6.36

- He, D., Pang, Y., Lodewijks, G., Liu, X. (2018). Healthy speed control of belt conveyors on conveying bulk materials. Powder Technology, 327, 408–419. doi: https://doi.org/10.1016/j.powtec.2018.01.002

- Korniienko, V. I., Matsiuk, S. M., Udovyk, I. M. (2018). Adaptive optimal control system of ore large crushing process. Radio Electronics, Computer Science, Control, 1, 159–165. doi: https://doi.org/10.15588/1607-3274-2018-1-18

- Kiriia, R., Shyrin, L. (2019). Reducing the energy consumption of the conveyor transport system of mining enterprises. E3S Web of Conferences, 109, 00036. doi: https://doi.org/10.1051/e3sconf/201910900036

- Pihnastyi, O., Kozhevnikov, G., Khodusov, V. (2020). Conveyor Model with Input and Output Accumulating Bunker. 2020 IEEE 11th International Conference on Dependable Systems, Services and Technologies (DESSERT). doi: https://doi.org/10.1109/dessert50317.2020.9124996

- Woo, C. K., Sreedharan, P., Hargreaves, J., Kahrl, F., Wang, J., Horowitz, I. (2014). A review of electricity product differentiation. Applied Energy, 114, 262–272. doi: https://doi.org/10.1016/j.apenergy.2013.09.070

- Cousins, T. (2010). Using Time of Use (TOU) Tariffs in Industrial, Commercial and Residential Applications Effectively. TLC. Available at: http://www.tlc.co.za/white_papers/pdf/using_time_of_use_tariffs_in_industrial_commercial_and_residential_applications_effectively.pdf

- Granell, R., Axon, C. J., Wallom, D. C. H. (2014). Predicting winning and losing businesses when changing electricity tariffs. Applied Energy, 133, 298–307. https://doi.org/10.1016/j.apenergy.2014.07.098

- Marais, J., Mathews, E., Pelzer, R. (2008). Analysing DSM opportunities on mine conveyor systems. In: Industrial and commercial use of energy conference. Cape Town.

- Wolstenholme, E. F. (1980). Designing and Assessing the Benefits of Control Policies for Conveyor Belt Systems in Underground Coal Mines. Dynamica, 6 (2), 25–35. Available at: https://systemdynamics.org/wp-content/uploads/assets/dynamica/volume-6/6-2/6.pdf

- Kazakova, E. I., Govorukha, E. N. (2019). Optimal proactive management of cargo flows. Austrian Journal of Technical and Natural Sciences, 7-8, 25–28. doi: https://doi.org/10.29013/ajt-19-7.8-25-28

- Bardzinski, P., Jurdziak, L., Kawalec, W., Król, R. (2019). Copper Ore Quality Tracking in a Belt Conveyor System Using Simulation Tools. Natural Resources Research, 29 (2), 1031–1040. doi: https://doi.org/10.1007/s11053-019-09493-6

- Pihnastyi, O., Khodusov, V. (2020) Neural model of conveyor type transport system. CEUR Workshop Proceedings, 2608. Available at: http://ceur-ws.org/Vol-2608/paper60.pdf

- Więcek, D., Burduk, A., Kuric, I. (2019). The use of ANN in improving efficiency and ensuring the stability of the copper ore mining process. Acta Montanistica Slovaca, 24 (1), 1–14. Available at: https://actamont.tuke.sk/pdf/2019/n1/1wiecek.pdf

- Dong, M., Luo, Q. (2011). Research and Application on Energy Saving of Port Belt Conveyor. Procedia Environmental Sciences, 10, 32–38. doi: https://doi.org/10.1016/j.proenv.2011.09.007

- Pihnastyi, O. M. (2018). Statistical theory of control systems of the flow production. LAP LAMBERT Academic Publishing, 436.

- Pihnastyi, O. M., Khodusov, V. D. (2020). Hydrodynamic Model of Transport System. East European Journal of Physics, 1, 121–136. doi: https://doi.org/10.26565/2312-4334-2020-1-11

- Pihnastyi, O., Khodusov, V., Kotova, A. (2022). The Problem of Combined Optimal Load Flow Control of Main Conveyor Line. Acta Montanistica Slovaca, 27 (1), 216–229. doi: https://doi.org/10.46544/ams.v27i1.16

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 Oleh Pihnastyi, Svіtlana Chernіavska

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.