Determining the effective mode of operation for the system of washing the milking machine milk supply line

DOI:

https://doi.org/10.15587/1729-4061.2022.265778Keywords:

milking equipment, cleaning process, washing the milk line, water flow rate, energy consumptionAbstract

The application of techniques for effective cleaning of milking routes in milking machines is an important way to improve the quality of milk and increase labor productivity in dairy farming.

The object of research was the system of washing the milk line of the milking machine with the upper milk line.

The problem of rational use of energy resources was solved in the implementation of a routine operation – washing the milking machine.

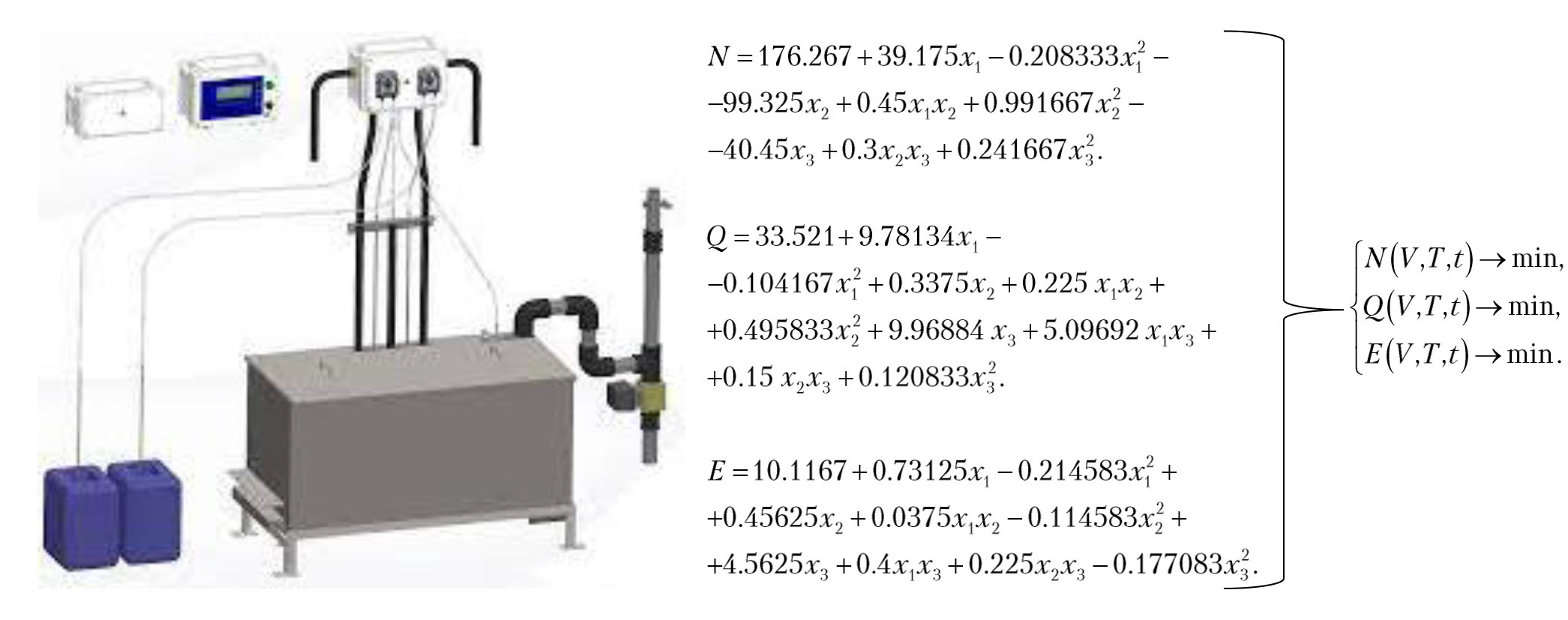

Experimental studies were carried out according to the Box-Benkin plan of the second order for 3 factors (the speed of movement of the washing solution, V; the temperature of the washing solution, T; the duration of the rinsing phase, t). In this case, a mathematical apparatus for planning a multivariate experiment according to the D-optimal plan was used.

It was found that with an increase in the speed of movement of the washing solution and temperature, as well as the duration of the rinsing phase, the number of microorganisms on the surfaces of the nodes and elements of the milky line decreases. Milk lines of the milking machine made of any material are better cleaned with a hotter washing solution (40 °C) than with a cold one (20 °C). Thus, when cleaning with a solution of 40 °C of stainless steel and food aluminum, the reduction of microorganisms is 4.3 times, glass – 4 times, and rubber – 4.7.

The essence of the experiment was to establish patterns when cleaning the milk line from various materials.

The influence of the regime parameters (the speed of movement of the washing solution, V; its temperature, T; and the duration of the rinsing phase, t) on the energy consumption of the milking machine, E, was determined.

The compromise problem of rationalizing the washing modes of the milk lines of the milking machine has been solved. Thus, rational mode parameters for the washing system were established: V=2.4 m/s, T=38.2 °C, t=3.2 minutes. With these parameters, the optimization criteria are: N=79 thousand CFU/cm3, Q=23.3 l, E=8.08 kWh

References

- Skarbye, A. P., Thomsen, P. T., Krogh, M. A., Svennesen, L., Østergaard, S. (2020). Effect of automatic cluster flushing on the concentration of Staphylococcus aureus in teat cup liners. Journal of Dairy Science, 103 (6), 5431–5439. doi: https://doi.org/10.3168/jds.2019-17785

- Shkromada, O., Skliar, O., Pikhtirova, A., Inessa, G. (2019). Pathogens transmission and cytological composition of cow’s milk. Acta Veterinaria Eurasia, 45, 73–79. doi: https://doi.org/10.26650/actavet.2019.19004

- Kukhtyn, M., Berhilevych, O., Kravcheniuk, K., Shynkaruk, O., Horyuk, Y., Semaniuk, N. (2017). The influence of disinfectants on microbial biofilms of dairy equipment. EUREKA: Life Sciences, 5, 11–17. doi: https://doi.org/10.21303/2504-5695.2017.00423

- Paliy, A., Aliiev, E., Paliy, A., Ishchenko, K., Lukyanov, I., Dobrovolsky, V. et. al. (2021). Revealing changes in the technical parameters of the teat cup liners of milking machines during testing and production conditions. EUREKA: Physics and Engineering, 6, 102–111. doi: https://doi.org/10.21303/2461-4262.2021.002056

- Wang, X., Demirci, A., Graves, R. E., Puri, V. M. (2019). Conventional and Emerging Clean-in-Place Methods for the Milking Systems. Raw Milk, 91–115. doi: https://doi.org/10.1016/b978-0-12-810530-6.00005-5

- Memisi, N., Moracanin, S. V., Milijasevic, M., Babic, J., Djukic, D. (2015). CIP Cleaning Processes in the Dairy Industry. Procedia Food Science, 5, 184–186. doi: https://doi.org/10.1016/j.profoo.2015.09.052

- Bava, L., Zucali, M., Sandrucci, A., Brasca, M., Vanoni, L., Zanini, L., Tamburini, A. (2011). Effect of cleaning procedure and hygienic condition of milking equipment on bacterial count of bulk tank milk. Journal of Dairy Research, 78 (2), 211–219. doi: https://doi.org/10.1017/s002202991100001x

- Dzidic, A., Macuhova, J., Bruckmaier, R. M. (2004). Effects of Cleaning Duration and Water Temperature on Oxytocin Release and Milk Removal in an Automatic Milking System. Journal of Dairy Science, 87 (12), 4163–4169. doi: https://doi.org/10.3168/jds.s0022-0302(04)73559-6

- Sundberg, M., Christiansson, A., Lindahl, C., Wahlund, L., Birgersson, C. (2010). Cleaning effectiveness of chlorine-free detergents for use on dairy farms. Journal of Dairy Research, 78 (1), 105–110. doi: https://doi.org/10.1017/s0022029910000762

- Willers, C. D., Ferraz, S. P., Carvalho, L. S., Rodrigues, L. B. (2014). Determination of indirect water consumption and suggestions for cleaner production initiatives for the milk-producing sector in a Brazilian middle-sized dairy farming. Journal of Cleaner Production, 72, 146–152. doi: https://doi.org/10.1016/j.jclepro.2014.02.055

- Gleeson, D., Paludetti, L., O’Brien, B., Beresford, T. (2022). Effect of ‘chlorine‐free’ cleaning of milking equipment on the microbiological quality and chlorine‐related residues in bulk tank milk. International Journal of Dairy Technology, 75 (2), 262–269. doi: https://doi.org/10.1111/1471-0307.12853

- Kompaniya TOV «AHRO-PROMSERVIS». Available at: https://agropromservis.net.ua/

- Shyhorin, P. P. (2009). Matematychni obchyslennia v prohramnomu paketi Mathematica 5. Lutsk: RVV "Vezha" Volyn. nats. un-tu im. Lesi Ukrainky, 48. Available at: https://evnuir.vnu.edu.ua/bitstream/123456789/18858/1/WolframMath.pdf

- Paliy, A., Aliiev, E., Nanka, A., Bogomolov, O., Bredixin, V., Paliy, A. et. al. (2021). Identifying changes in the technical parameters of milking rubber under industrial conditions to elucidate their effect on the milking process. Eastern-European Journal of Enterprise Technologies, 3 (1 (111)), 21–29. doi: https://doi.org/10.15587/1729-4061.2021.231917

- Marchand, S., De Block, J., De Jonghe, V., Coorevits, A., Heyndrickx, M., Herman, L. (2012). Biofilm Formation in Milk Production and Processing Environments; Influence on Milk Quality and Safety. Comprehensive Reviews in Food Science and Food Safety, 11 (2), 133–147. doi: https://doi.org/10.1111/j.1541-4337.2011.00183.x

- Krushelnytska, N. V. (2015). The influence of sanitary processing of milking equipment and milking technologies on hygienic quality of milk. Naukovyi visnyk Lvivskoho natsionalnoho universytetu veterynarnoi medytsyny ta biotekhnolohii im. Gzhytskoho, 15 (1 (55)), 93–97.

- Paliy, A., Aliiev, E., Paliy, A., Nechyporenko, O., Baidevliatova, Y., Baydevliatov, Y. et. al. (2021). Determining the efficiency of cleaning a milk line made from different materials from contaminants. Eastern-European Journal of Enterprise Technologies, 4 (1 (112)), 76–85. doi: https://doi.org/10.15587/1729-4061.2021.237070

- Fan, M., Phinney, D. M., Heldman, D. R. (2015). Effectiveness of Rinse Water during In-Place Cleaning of Stainless Steel Pipe Lines. Journal of Food Science, 80 (7), E1490–E1497. doi: https://doi.org/10.1111/1750-3841.12914

- Calcante, A., Tangorra, F. M., Oberti, R. (2016). Analysis of electric energy consumption of automatic milking systems in different configurations and operative conditions. Journal of Dairy Science, 99 (5), 4043–4047. doi: https://doi.org/10.3168/jds.2015-10490

- Paliy, A., Aliiev, E., Paliy, A., Ishchenko, K., Shkromada, O., Musiienko, Y. et. al. (2021). Development of a device for cleansing cow udder teats and testing it under industrial conditions. Eastern-European Journal of Enterprise Technologies, 1 (1 (109)), 43–53. doi: https://doi.org/10.15587/1729-4061.2021.224927

- Boguniewicz-Zablocka, J., Klosok-Bazan, I., Naddeo, V. (2017). Water quality and resource management in the dairy industry. Environmental Science and Pollution Research, 26 (2), 1208–1216. doi: https://doi.org/10.1007/s11356-017-0608-8

- Aliiev, E., Paliy, A., Kis, V., Paliy, A., Petrov, R., Plyuta, L. et. al. (2022). Establishing the influence of technical and technological parameters of milking equipment on the efficiency of machine milking. Eastern-European Journal of Enterprise Technologies, 1 (1 (115)), 44–55. doi: https://doi.org/10.15587/1729-4061.2022.251172

- Gaworski, M. (2021). Implementation of Technical and Technological Progress in Dairy Production. Processes, 9 (12), 2103. doi: https://doi.org/10.3390/pr9122103

- Aliiev, E., Paliy, A., Dudin, V., Kis, V., Paliy, A., Ostapenko, V. et. al. (2022). Establishing an interconnection between the technical and technological parameters of milking equipment based on the movement of a milk-air mixture in a milking machine. Eastern-European Journal of Enterprise Technologies, 2 (1 (116)), 35–46. doi: https://doi.org/10.15587/1729-4061.2022.253978

- Nimbalkar, V., Kumar Verma, H., Singh, J. (2021). Dairy Farming Innovations for Productivity Enhancement. New Advances in the Dairy Industry. doi: https://doi.org/10.5772/intechopen.101373

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 Andriy Paliy, Elchyn Aliiev, Anatoliy Paliy, Yana Kotko, Ruslan Kolinchuk, Evgenia Livoschenko, Oleksandr Chekan, Svitlana Nazarenko, Ludmila Livoschenko, Liliya Uskova

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.