Effect of layered double hydroxides Ca-Al LDHs and polycarboxylate ethers on the hardening of Portland limestone cement

DOI:

https://doi.org/10.15587/1729-4061.2022.266269Keywords:

Portland limestone cement, layered double hydroxides, polycarboxylate ethers, nanocomposite Ca-Al-NO3 LDHs–PCE, strengthAbstract

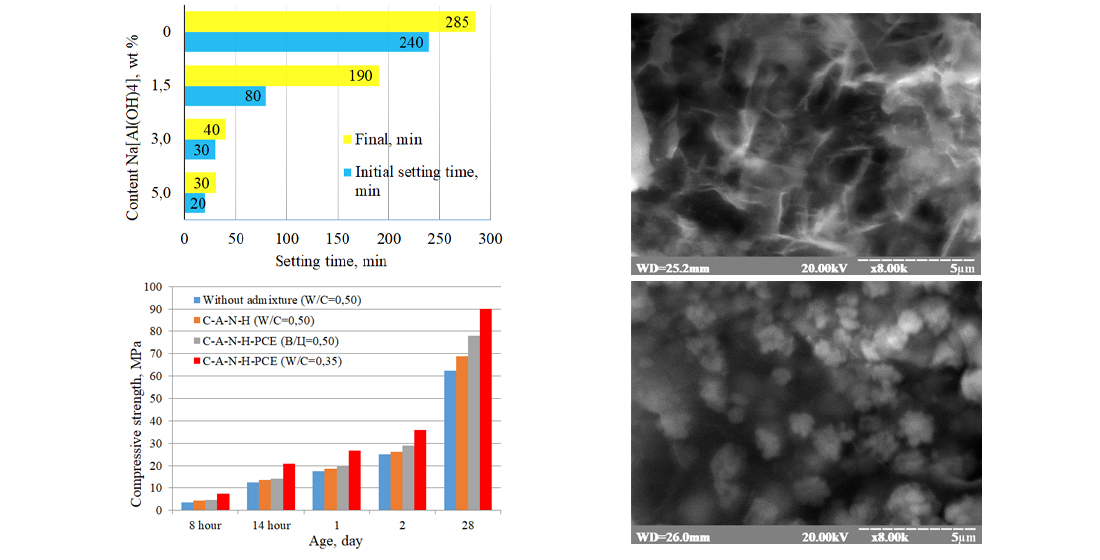

The use of layered double hydroxides (LDHs) is a new direction in chemistry of cement. The influence of calcium/aluminum double hydroxides (Ca-Al LDHs) and polycarboxylate ethers (PCE) on the strength development of Portland limestone cement has been investigated. It has been shown that Ca-Al LDHs form in cement slurry with the introduction of alkaline aluminate accelerator Na[Al(OH)4]. It was determined that this contributes to a significant increase in the early strength of cement stone. However, this reduces the setting time of hardening, and there is a decrease in strength with age. At an early stage of structuring in cement paste with the addition of Na[Al(OH)4], metastable high-water hydrate phases of Ca-Al LDHs of type C4AH19 ([Ca2Al(OH)6]2(ОН)2·12H2O) are formed, which, due to the conversion phenomenon, transform to cubic C3AH6. Such processes are accompanied by an increase in overall porosity and decreases in the strength of cement stone. Stabilization of the Ca-Al LDH structure is achieved by introducing anions [NO3]- into the interlayer space with the formation of Ca-Al-NO3 LDHs through the use of sol-gel technology. X-ray phase analysis, IR spectroscopy, and electron microscopy proved the fact of synthesis of AFm-phases of type [Ca2Al(OH)6]2(NO3)2.6H2О. When modifying such hydrates with polycarboxylate ethers, a nanocomposite Ca-Al-NO3 LDHs-РСЕ is formed. It was found that when the Ca-Al-NO3 LDHs-РСЕ nanocomposite was introduced to СЕМ ІІ/A-LL 42,5 R, the strength over the period of 8...24 hours increases by 2.0–1.5 times, and, after 2 and 28 days, 58 and 144 % of the standard strength is achieved (Rс28=62.5 MPa). The obtained nanomodified Portland limestone cement refers to extra rapid-hardening and high-strength cement, which makes it possible to solve the task of carrying out work on the rapid restoration of reinforced concrete structures' elements

References

- Shi, C., Qu, B., Provis, J. L. (2019). Recent progress in low-carbon binders. Cement and Concrete Research, 122, 227–250. doi: https://doi.org/10.1016/j.cemconres.2019.05.009

- Sanytsky, M., Kropyvnytska, T., Fic, S., Ivashchyshyn, H. (2020). Sustainable low-carbon binders and concretes. E3S Web of Conferences, 166, 06007. doi: https://doi.org/10.1051/e3sconf/202016606007

- Song, X., Song, X., Liu, H., Huang, H., Anvarovna, K. G., Ugli, N. A. D. et al. (2022). Cement-Based Repair Materials and the Interface with Concrete Substrates: Characterization, Evaluation and Improvement. Polymers, 14 (7), 1485. doi: https://doi.org/10.3390/polym14071485

- Kroviakov, S., Volchuk, V., Zavoloka, M., Kryzhanovskyi, V. (2019). Search for Ranking Approaches of Expanded Clay Concrete Quality Criteria. Materials Science Forum, 968, 20–25. doi: https://doi.org/10.4028/www.scientific.net/msf.968.20

- Kovalchuk, O., Grabovchak, V., Govdun, Y. (2018). Alkali activated cements mix design for concretes application in high corrosive conditions. MATEC Web of Conferences, 230, 03007. doi: https://doi.org/10.1051/matecconf/201823003007

- Krivenko, P. V., Sanytsky, M., Kropyvnytska, T., Kotiv, R. (2014). Decorative Multi-Component Alkali Activated Cements for Restoration and Finishing Works. Advanced Materials Research, 897, 45–48. doi: https://doi.org/10.4028/www.scientific.net/amr.897.45

- Xu Q., Stark, J. (2005). Early hydration of ordinary Portland cement with an alkaline shotcrete accelerator. Advances in Cement Research, 17, (1), 1–8. doi: https://doi.org/10.1680/adcr.17.1.1.58390

- Xu, Q., Stark, J. (2008). A model of early cement hydration with an alkaline setting accelerator. Cement international, 1, 67–74.

- Salvador, R. P., Cavalaro, S. H. P., Segura, I., Figueiredo, A. D., Pérez, J. (2016). Early age hydration of cement pastes with alkaline and alkali-free accelerators for sprayed concrete. Construction and Building Materials, 111, 386–398. doi: https://doi.org/10.1016/j.conbuildmat.2016.02.101

- Kropyvnytska, T. P., Kaminskyy, A. T., Semeniv, R. M., Chekaylo, M. V. (2019). The effect of sodium aluminate on the properties of the composite cements. IOP Conference Series: Materials Science and Engineering, 708 (1), 012091. doi: https://doi.org/10.1088/1757-899x/708/1/012091

- Sanytsky, M., Usherov-Marshak, A., Kropyvnytska, T., Heviuk, I. (2020). Performance of multicomponent portland cements containing granulated blast furnace slag, zeolite, and limestone. Cement Wapno Beton, 25 (5), 416–427. doi: https://doi.org/10.32047/CWB.2020.25.5.7

- Ivashchyshyn, H., Sanytsky, M., Kropyvnytska, T., Rusyn, B. (2019). Study of low-emission multi-component cements with a high content of supplementary cementitious materials. Eastern-European Journal of Enterprise Technologies, 4 (6 (100)), 39–47. doi: doi: https://doi.org/10.15587/1729-4061.2019.175472

- Andersen, M. D., Jakobsen, H. J., Skibsted, J. (2004). Characterization of white Portland cement hydration and the C-S-H structure in the presence of sodium aluminate by 27Al and 29Si MAS NMR spectroscopy. Cement and Concrete Research, 34 (5), 857–868. doi: https://doi.org/10.1016/j.cemconres.2003.10.009

- Han, J., Wang, K., Shi, J., Wang, Y. (2014). Influence of sodium aluminate on cement hydration and concrete properties. Construction and Building Materials, 64, 342–349. doi: https://doi.org/10.1016/j.conbuildmat.2014.04.089

- Pushkarova, K., Kaverin, K., Kalantaevsky, D. (2015). Research of high-strength cement compositions modified by complex organic-silica additives. Eastern-European Journal of Enterprise Technologies, 5 (5 (77)), 42–51. doi: https://doi.org/10.15587/1729-4061.2015.51836

- Kryvenko, P., Runova, R., Rudenko, I., Skorik, V., Omelchuk, V. (2017). Analysis of plasticizer effectiveness during alkaline cement structure formation. Eastern-European Journal of Enterprise Technologies, 4 (6 (88)), 35–41. doi: https://doi.org/10.15587/1729-4061.2017.106803

- Luo, B., Luo, Z., Wang, D., Shen, C., Xia, M. (2021). Influence of alkaline and alkali-free accelerators on strength, hydration and microstructure characteristics of ultra-high performance concrete. Journal of Materials Research and Technology, 15, 3283–3295. doi: https://doi.org/10.1016/j.jmrt.2021.09.133

- Su, Y., Luo, B., Luo, Z., Huang, H., Li, J., Wang, D. (2021). Effect of Accelerators on the Workability, Strength, and Microstructure of Ultra-High-Performance Concrete. Materials, 15 (1), 159. doi: https://doi.org/10.3390/ma15010159

- Sikora, P., Abd Elrahman, M., Stephan, D. (2018). The Influence of Nanomaterials on the Thermal Resistance of Cement-Based Composites – A Review. Nanomaterials, 8 (7), 465. doi: https://doi.org/10.3390/nano8070465

- Fic, S., Klonica, M., Szewczak, A. (2015). Adhesive properties of low molecular weight polymer modified with nanosilica and disintegrated ultrasonically for application in waterproofing ceramics. Polimery, 61 (11/12), 730–734. doi: https://doi.org/10.14314/polimery.2015.730

- Marushchak, U., Sanytsky, M., Olevych, Y. (2017). Effects of elevated temperatures on the properties of nanomodified rapid hardening concretes. MATEC Web of Conferences, 116, 01008. doi: https://doi.org/10.1051/matecconf/201711601008

- Kropyvnytska, T., Semeniv, R., Kotiv, R., Kaminskyy, A., Hots, V. (2018). Studying the efect of nanoliquids on the operational properties of brick building structures. Eastern-European Journal of Enterprise Technologies, 5 (6 (95)), 27–32. doi: https://doi.org/10.15587/1729-4061.2018.145246

- Kanchanason, V., Plank, J. (2019). Effect of calcium silicate hydrate – polycarboxylate ether (C-S-H–PCE) nanocomposite as accelerating admixture on early strength enhancement of slag and calcined clay blended cements. Cement and Concrete Research, 119, 44–50. doi: https://doi.org/10.1016/j.cemconres.2019.01.007

- Kropyvnytska, T., Sanytsky, M., Rucińska, T., Rykhlitska, O. (2019). Development of nanomodified rapid hardening clinker-efficient concretes based on composite Portland cements. Eastern-European Journal of Enterprise Technologies, 6 (6 (102)), 38–48. doi: https://doi.org/10.15587/1729-4061.2019.185111

- Sanytsky, M., Kropyvnytska, T., Нeviuk, I., Sikora, P., Braichenko, S. (2021). Development of rapid-hardening ultra-high strength cementitious composites using superzeolite and N-C-S-H-PCE alkaline nanomodifier. Eastern-European Journal of Enterprise Technologies, 5 (6 (113)), 62–72. doi: https://doi.org/10.15587/1729-4061.2021.242813

- Hohol, M., Sanytsky, M., Kropyvnytska, T., Barylyak, A., Bobitski, Y. (2020). The effect of sulfur- and carbon-codoped TiO2 nanocomposite on the photocatalytic and mechanical properties of cement mortars. Eastern-European Journal of Enterprise Technologies, 4 (6 (106)), 6–14. doi: https://doi.org/10.15587/1729-4061.2020.210218

- Skripkiūnas, G., Kičaitė, A., Justnes, H., Pundienė, I. (2021). Effect of Calcium Nitrate on the Properties of Portland–Limestone Cement-Based Concrete Cured at Low Temperature. Materials, 14 (7), 1611. doi: https://doi.org/10.3390/ma14071611

- Plugin, A. A., Runova, R. F. (2018). Bonding Calcium Chloride and Calcium Nitrate into Stable Hydration Portland Cement Products: Stability Conditions of Calcium Hydrochloraluminates and Calcium Hydronitroaluminates. International Journal of Engineering Research in Africa, 36, 69–73. doi: https://doi.org/10.4028/www.scientific.net/jera.36.69

- Xu, Y., He, T., Ma, X. (2022). The influence of calcium nitrate/sodium nitrate on the hydration process of cement paste mixed with alkali free liquid accelerator. Construction and Building Materials, 347, 128555. doi: https://doi.org/10.1016/j.conbuildmat.2022.128555

- Pushpakumara, B. H. J., Sudhira De Silva, G., Subashi De Silva, G. H. M. J. (2013). Calcium nitrate mixed cement mortar for repairing corroded RC structures. Construction Materials and Systems. Available at: https://www.researchgate.net/publication/352776327

- Markiv, T., Blikharskyy, Z. (2022). Effect of Calcium Nitrate-Based Admixture on the Strength of Concrete and Corrosion Susceptibility of Reinforcing Steel Bars. Proceedings of EcoComfort 2022, 253–261. doi: https://doi.org/10.1007/978-3-031-14141-6_25

- Mir, Z. M., Bastos, A., Höche, D., Zheludkevich, M. L. (2020). Recent Advances on the Application of Layered Double Hydroxides in Concrete – A Review. Materials, 13 (6), 1426. doi: https://doi.org/10.3390/ma13061426

- Qiu, Z., Deng, L., Lu, S., Li, G., Tang, Z. (2022). Effect of LDH on the dissolution and adsorption behaviors of sulfate in Portland cement early hydration process. REVIEWS ON ADVANCED MATERIALS SCIENCE, 61 (1), 381–393. doi: https://doi.org/10.1515/rams-2022-0039

- Khan, A. I., O’Hare, D. (2002). Intercalation chemistry of layered double hydroxides: recent developments and applications. Journal of Materials Chemistry, 12 (11), 3191–3198. doi: https://doi.org/10.1039/b204076j

- Szymanowski, Sadowski. (2019). The Development of Nanoalumina-Based Cement Mortars for Overlay Applications in Concrete Floors. Materials, 12 (21), 3465. doi: https://doi.org/10.3390/ma12213465

- Hongo, T., Tsunashima, Y., Yamasaki, A. (2017). Synthesis of Ca-Al layered double hydroxide from concrete sludge and evaluation of its chromate removal ability. Sustainable Materials and Technologies, 12, 23–26. doi: https://doi.org/10.1016/j.susmat.2017.04.001

- Qu, Z. Y., Yu, Q. L., Brouwers, H. J. H. (2018). Relationship between the particle size and dosage of LDHs and concrete resistance against chloride ingress. Cement and Concrete Research, 105, 81–90. doi: https://doi.org/10.1016/j.cemconres.2018.01.005

- Zhang, S., Yu, F., He, W., Zheng, D., Cui, H., Lv, L. et al. (2020). Experimental Investigation of Chloride Uptake Performances of Hydrocalumite-Like Ca-Al LDHs with Different Microstructures. Applied Sciences, 10 (11), 3760. doi: https://doi.org/10.3390/app10113760

- Kim, G., Park, S. (2021). Chloride Removal of Calcium Aluminate-Layered Double Hydroxide Phases: A Review. International Journal of Environmental Research and Public Health, 18 (6), 2797. doi: https://doi.org/10.3390/ijerph18062797

- Gevers, B. R., Labuschagné, F. J. W. J. (2020). Green Synthesis of Hydrocalumite (CaAl-OH-LDH) from Ca(OH)2 and Al(OH)3 and the Parameters That Influence Its Formation and Speciation. Crystals, 10 (8), 672. doi: https://doi.org/10.3390/cryst10080672

- Sanchez, F., Sobolev, K. (2010). Nanotechnology in concrete – A review. Construction and Building Materials, 24 (11), 2060–2071. doi: https://doi.org/10.1016/j.conbuildmat.2010.03.014

- Federowicz, K., Techman, M., Sanytsky, M., Sikora, P. (2021). Modification of Lightweight Aggregate Concretes with Silica Nanoparticles – A Review. Materials, 14 (15), 4242. doi: https://doi.org/10.3390/ma14154242

- Taylor, H. F. W. (1973). Crystal structures of some double hydroxide minerals. Mineralogical Magazine, 39 (304), 377–389. doi: https://doi.org/10.1180/minmag.1973.039.304.01

- Yang, L., Zhao, P., Liang, C., Chen, M., Niu, L., Xu, J., Sun, D., Lu, L. (2021). Characterization and adaptability of layered double hydroxides in cement paste. Applied Clay Science, 211, 106197. doi: https://doi.org/10.1016/j.clay.2021.106197

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 Tetiana Kropyvnytska, Myroslav Sanytsky, Andrii Kaminskyi, Orest Vakhula

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.