Improvement of Turkish delight production technology using a developed multi-component fruit and vegetable paste

DOI:

https://doi.org/10.15587/1729-4061.2022.269393Keywords:

Turkish delight, fruit and vegetable paste, structural and mechanical properties, physiologically functional ingredients, quality indicatorsAbstract

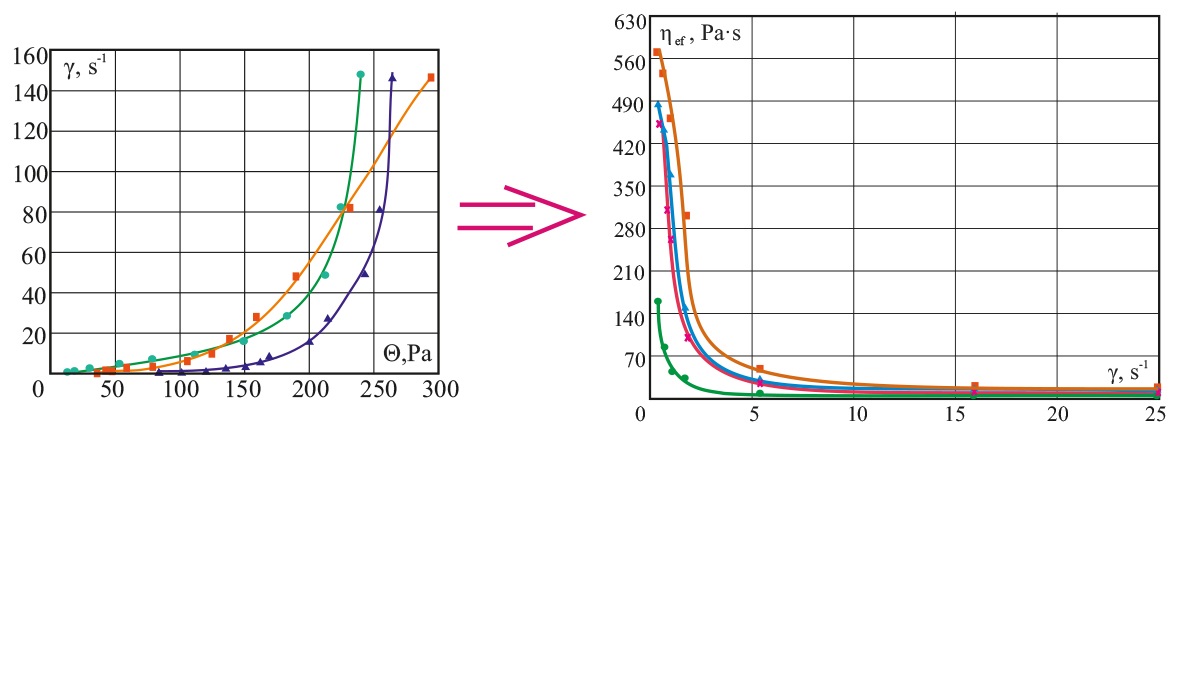

The object of this study is the technology of Turkish delight production based on fruit and vegetable paste with a high content of physiologically functional ingredients. The chemical composition of Turkish delight has been optimized by introducing physiologically functional ingredients. As a source of physiologically functional ingredients, it was proposed to use a multicomponent fruit and vegetable paste from apples, quince, pumpkins, made in an improved way. The technique is characterized by concentrating the paste in the rotary evaporator for 30...42 s at a temperature of 60...63 °C under conditions of preheating the purée to 50...52 °C. The dependence of the effective viscosity on the shear rate of samples of fruit and vegetable pastes was determined and it was found that the best indicators characterized the paste with a formulation ratio of raw materials: apple – 30 %; quince – 50 %; pumpkin – 20 %. The resulting paste has good organoleptic properties and a high content of dietary fiber, ascorbic acid, polyphenolic compounds.

It has been established that the production of Turkish delight with the addition of the developed fruit and vegetable paste provides the product with good organoleptic characteristics. Namely, it is characterized by a sweet-sour taste with a pleasant smell of quince, rich yellow-orange color, gelatinous, slightly viscous consistency, and the proper shape with a clear contour. Also, the addition of fruit and vegetable paste reduces the formulation amount of starch by 20 % while the resulting Turkish delight is characterized by a high strength value τ=38 kPa.

The improved technology of Turkish delight could expand the range of "healthy products" with increased nutritional value. In addition, the proposed technique and the modes of concentration make it possible to organize the process of paste production using energy-saving equipment.

References

- Konar, N., Gunes, R., Palabiyik, I., Toker, O. S. (2022). Health conscious consumers and sugar confectionery: Present aspects and projections. Trends in Food Science & Technology, 123, 57–68. doi: https://doi.org/10.1016/j.tifs.2022.02.001

- Bursać Kovačević, D., Brdar, D., Fabečić, P., Barba, F. J., Lorenzo, J. M., Putnik, P. (2020). Strategies to achieve a healthy and balanced diet: fruits and vegetables as a natural source of bioactive compounds. Agri-Food Industry Strategies for Healthy Diets and Sustainability, 51–88. doi: https://doi.org/10.1016/b978-0-12-817226-1.00002-3

- Pap, N., Fidelis, M., Azevedo, L., do Carmo, M. A. V., Wang, D., Mocan, A. et al. (2021). Berry polyphenols and human health: evidence of antioxidant, anti-inflammatory, microbiota modulation, and cell-protecting effects. Current Opinion in Food Science, 42, 167–186. doi: https://doi.org/10.1016/j.cofs.2021.06.003

- Batu, A., Kirmaci, B. (2009). Production of Turkish delight (lokum). Food Research International, 42 (1), 1–7. doi: https://doi.org/10.1016/j.foodres.2008.08.007

- Richmond, R., Bowyer, M., Vuong, Q. (2019). Australian native fruits: Potential uses as functional food ingredients. Journal of Functional Foods, 62, 103547. doi: https://doi.org/10.1016/j.jff.2019.103547

- Gunes, R., Palabiyik, I., Konar, N., Said Toker, O. (2022). Soft confectionery products: Quality parameters, interactions with processing and ingredients. Food Chemistry, 385, 132735. doi: https://doi.org/10.1016/j.foodchem.2022.132735

- Kavak, D. D., Akpunar, E. B. (2018). Quality characteristics of Turkish delight (lokum) as influenced by different concentrations of cornelian cherry pulp. Journal of Food Processing and Preservation, 42 (7), e13656. doi: https://doi.org/10.1111/jfpp.13656

- Mohammadi-Moghaddam, T., Firoozzare, A., Kariminejad, M., Sorahi, M., Tavakoli, Z. (2020). Black plum peel as a useful by-product for the production of new foods: chemical, textural, and sensory characteristics of Halva Masghati. International Journal of Food Properties, 23 (1), 2005–2019. doi: https://doi.org/10.1080/10942912.2020.1835953

- Dirik, A. (2009). Nar Ve Nar Suyunun Lokum Üretiminde Kullanim Olanaklari. Şanliurfa. Available at: http://acikerisim.harran.edu.tr:8080/jspui/bitstream/11513/982/1/252149.pdf

- Kaya, C., Güldane, M., Topuz, S., Bayram, M. (2018). Determination of Some Properties of Turkish Delight Produced by the Addition of Pomegranate Juice. Turkish Journal of Agriculture - Food Science and Technology, 6 (12), 1814. doi: https://doi.org/10.24925/turjaf.v6i12.1814-1819.2176

- Başyiğit, B., Hayoğlu, İ. Dirik, A. (2017). Tane nar ilaveli lokum üretimi ve vakum ambalajlamanin raf ömrü üzerine etkisi. Gıda, 42 (5), 553–560. Available at: https://dergipark.org.tr/en/pub/gida/issue/29788/293278

- Ogun, S. (2019). Türk lokumu üretiminde ayva bitkisinin kullanılması ve depolama stabilitesinin araştırılması. Afyon Kocatepe Ünġversġtesġ Fen Bġlġmlerġ Enstġtüsü. Available at: http://acikerisim.aku.edu.tr/xmlui/handle/11630/7084

- Karakaş Budak, B. (2019). Effect of starch substitution with pullulan on confectionery starch gel texture of lokum. Mediterranean Agricultural Sciences, 32 (3), 323–327. doi: https://doi.org/10.29136/mediterranean.609017

- Samokhvalova, O., Kucheruk, Z., Kasabova, K., Oliinyk, S., Shmatchenko, N. (2021). Effect of microbial polysaccharides on the quality indicators of protein-free and gluten-free products during storage. Eastern-European Journal of Enterprise Technologies, 1 (11 (109)), 61–68. doi: https://doi.org/10.15587/1729-4061.2021.225003

- Samokhvalova, O., Kasabova, K., Oliinyk, S. (2014). The influence of the enriching additives on the dough structure formation and baked muffins. Eastern-European Journal of Enterprise Technologies, 1 (10 (67)), 32–36. https://doi.org/10.15587/1729-4061.2014.20024

- Batu, A., Arslan, A. (2014). Effects of Black Grape Syrup on Texture, Colour and Sensory Qualies of Value Added Turkish Delight (Lokum). Journal of Nutrition & Food Sciences, s8. doi: https://doi.org/10.4172/2155-9600.s8-005

- Çoban, B., Bilgin, B., Yurt, B., Kopuk, B., Atik, D. S., Palabiyik, I. (2021). Utilization of the barberry extract in the confectionery products. LWT, 145, 111362. doi: https://doi.org/10.1016/j.lwt.2021.111362

- Özen, G., Akbulut, M., Artik, N. (2009). Stability of black carrot anthocyanins in the turkish delight (lokum) during storage. Journal of Food Process Engineering, 34 (4), 1282–1297. doi: https://doi.org/10.1111/j.1745-4530.2009.00412.x

- Di Monaco, R., Miele, N. A., Cabisidan, E. K., Cavella, S. (2018). Strategies to reduce sugars in food. Current Opinion in Food Science, 19, 92–97. doi: https://doi.org/10.1016/j.cofs.2018.03.008

- Tavani, A., Giordano, L., Gallus, S., Talamini, R., Franceschi, S., Giacosa, A. et al. (2006). Consumption of sweet foods and breast cancer risk in Italy. Annals of Oncology, 17 (2), 341–345. doi: https://doi.org/10.1093/annonc/mdj051

- Hadjikinova, R., Hasan, Y. (2022). Isomaltulose as an alternative to sucrose in the composition of Turkish delight (lokum). BIO Web of Conferences, 45, 01007. doi: https://doi.org/10.1051/bioconf/20224501007

- Sevim Kaya, Gökçe Özkaleli Tattan. (2017). Thermal and Textural Changes of Turkish Delight with Storage Relative Humidity. Journal of Food Science and Engineering, 7 (4). doi: https://doi.org/10.17265/2159-5828/2017.04.002

- Golge, O., Hepsag, F., Kabak, B. (2016). Determination of aflatoxins in walnut sujuk and Turkish delight by HPLC-FLD method. Food Control, 59, 731–736. doi: https://doi.org/10.1016/j.foodcont.2015.06.035

- Kasabova, K., Zagorulko, A., Zahorulko, A., Shmatchenko, N., Simakova, O., Goriainova, I. et al. (2021). Improving pastille manufacturing technology using the developed multicomponent fruit and berry paste. Eastern-European Journal of Enterprise Technologies, 3 (11 (111)), 49–56. doi: https://doi.org/10.15587/1729-4061.2021.231730

- Samokhvalova, O., Kasabova, K., Shmatchenko, N., Zagorulko, A., Zahorulko, A. (2021). Improving the marmalade technology by adding a multicomponent fruit-and-berry paste. Eastern-European Journal of Enterprise Technologies, 6 (11 (114)), 6–14. doi: https://doi.org/10.15587/1729-4061.2021.245986

- Kasabova, K., Sabadash, S., Mohutova, V., Volokh, V., Poliakov, A., Lazarieva, T. et al. (2020). Improvement of a scraper heat exchanger for pre-heating plant-based raw materials before concentration. Eastern-European Journal of Enterprise Technologies, 3 (11 (105)), 6–12. doi: https://doi.org/10.15587/1729-4061.2020.202501

- Mykhailov, V., Zahorulko, A., Zagorulko, A., Liashenko, B., Dudnyk, S. (2021). Method for producing fruit paste using innovative equipment. Acta Innovations, 39, 15–21. doi: https://doi.org/10.32933/actainnovations.39.2

- Cherevko, A. I., Kiptelaya, L. V., Mihaylov, V. M., Zagorul'ko, A. E. (2009). Progressivnye protsessy kontsentrirovaniya netraditsionnogo plodoovoschnogo syr'ya. Kharkiv: HGUPT, 241.

- Hropot, O. A., Ivanov, M. M., Krotova, I. V. (2015). Sravnitel'nyy analiz himicheskogo sostava plodov tykvy raznyh sortov. Sibirskiy federal'niy universitet. Sel'skohozyaystvennye nauki, 2 (35), 15–19.

- Horalchuk, A. B. et al. (2006). Reolohichni metody doslidzhennia syrovyny i kharchovykh produktiv ta avtomatyzatsiia rozrakhunkiv reolohichnykh kharakterystyk. Kharkiv, 63.

- Tipsina, N. N. (2018). Vostochnye sladosti i natsional'nye izdeliya. Krasnoyarsk, 150. Available at: https://www.twirpx.com/file/3079130/

- DSTU 4688:2006. Turkish Toffies (Toffees Sweet Meats). General specifications. Available at: http://online.budstandart.com/ua/catalog/doc-page?id_doc=92591

- Cherevko, A., Mayak, O., Kostenko, S., Sardarov, A. (2019). Experimental and simulation modeling of the heat exchanche process while boiling vegetable juice. Prohresyvni tekhnika ta tekhnolohiyi kharchovykh vyrobnytstv restorannoho hospodarstva i torhivli, 1 (29), 75–85. Available at: https://repo.btu.kharkov.ua/handle/123456789/298

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 Kateryna Kasabova, Olga Samokhvalova, Aleksey Zagorulko, Andrii Zahorulko, Serhii Babaiev, Olena Bereza, Nataliia Ponomarenko, Hennadii Tesliuk, Viktor Yukhno

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.