Оцінка ефективності способів охорони підготовчих виробок на підставі порівняльного аналізу деформаційних характеристик охоронних споруд

DOI:

https://doi.org/10.15587/1729-4061.2023.272454Ключові слова:

вуглепородний масив, охоронні споруди, стиснення, деформаційні характеристики, потенціальна енергія, ущільнення, стійкістьАнотація

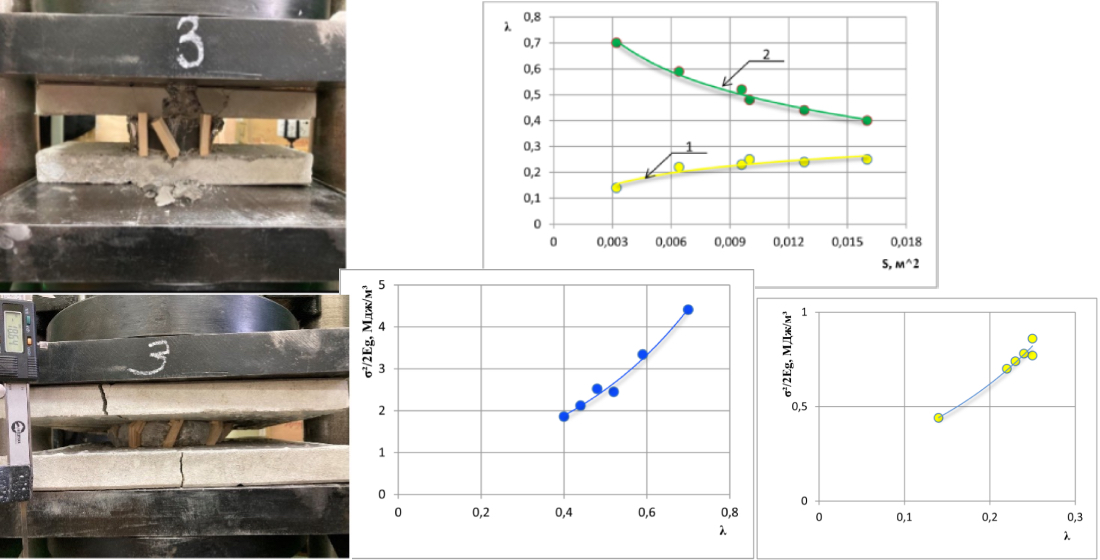

Об’єктом дослідження є процеси управління станом бічних порід у вуглепородному масиві з підготовчими виробками. Встановлено вплив деформаційних характеристик охоронних споруд підготовчих виробок на стійкість бічних порід у вуглепородному масиві. Стійкий стан надштрекових ціликів вугілля забезпечується в межах деформаційного ресурсу, якому відповідає критичний рівень питомої потенціальної енергії деформації. Межами деформаційного ресурсу є діапазон зміни відносної деформації ціликів вугілля 0,1≤λ≤0,25. При переході критичного рівня питомої потенціальної енергії деформації, коли λ˃0,25, настає відносна зміна об’єму ціликів δλ˃0,1, в результаті чого їх тримкість знижується, а стан змінюється.

В таких умовах залишкової міцності вугільних ціликів недостатньо для обмеження переміщення бічних порід, що і провокує їх обвалення.

Для охоронних споруд із подрібненої породи, в межах встановленого деформаційного ресурсу 0,4≤λ≤0,7, зі збільшенням статичного навантаження і площі поперечного перетину, питома потенціальна енергія деформації зменшується, одночасно з відносною зміною об’єму закладного матеріалу. Це пов’язано з ущільненням подрібненої породи і підвищенням величини їх тримкості..

Встановлені закономірності зміни питомої потенціальної енергії деформування охоронних споруд, які в умовах одновісного стиснення дозволяють оцінити, у межах деформаційного ресурсу, їх тримкість.

Для забезпечення стійкості бічних порід у вуглепородному масиві і збереження експлуатаційного стану підготовчих виробок, доцільно застосовувати охоронні споруди з подрібненої породи. Такий метод дозволить обмежити переміщення покрівлі і підошви у виробленому просторі та уникнути обвалень

Посилання

- Yakobi, O. (1987). Praktika upravleniya gornym davleniem. Moscow: Nedra, 566.

- Selezen', A. L., Tomasov, A. G., Andrushko, V. F. (1977). Podderzhanie podgotovitel'nyh vyrabotok pri razrabotke krutyh plastov. Moscow: Nedra, 205.

- Chepiga, D. (2019). Obgruntuvannia ta rozrobka sposobiv pidvyshchennia bezpeky pratsi hirnykiv u vyimkovykh dilnytsiakh hlybokykh vuhilnykh shakht. Pokrovsk: DonNTU, 24.

- Jie, C. (2019). Study on Reasonable Size of Coal Pillars in Large Dip Angle Coal Seam. 2019 International Conference on Environmental Protection, Coal Industry and Metallurgical Mine Safety (EPCIMMS 2019), 71–75. Available at: https://webofproceedings.org/proceedings_series/ESR/EPCIMMS%202019/EP015.pdf

- Zhaoyuan, L., Feng, C., Jianwei, L., Xingping, L., Ruiqiang, Y. (2021). Dynamic Evolution Law and Width Determination of Section Coal Pillars in Deep Mining Height Working Face. Research Square. doi: https://doi.org/10.21203/rs.3.rs-442910/v1

- Zhang, K., Wu, F., Yue, X. (2022). Study on Reasonable Chain Pillar Size in a Thick Coal Seam. Geofluids, 2022, 1–14. doi: https://doi.org/10.1155/2022/7290894

- Iordanov, I., Buleha, I., Bachurina, Y., Boichenko, H., Dovgal, V., Kayun, O. et al. (2021). Experimental research on the haulage drifts stability in steeply dipping seams. Mining of Mineral Deposits, 15 (4), 56–67. doi: https://doi.org/10.33271/mining15.04.056

- Petlovanyi, M., Malashkevych, D., Sai, K., Zubko, S. (2020). Research into balance of rocks and underground cavities formation in the coal mine flowsheet when mining thin seams. Mining of Mineral Deposits, 14 (4), 66–81. doi: https://doi.org/10.33271/mining14.04.066

- Petlovanyi, M., Malashkevych, D., Sai, K., Bulat, I., Popovych, V. (2021). Granulometric composition research of mine rocks as a material for backfilling the mined-out area in coal mines. Mining of Mineral Deposits, 15 (4), 122–129. doi: https://doi.org/10.33271/mining15.04.122

- Chen, D., Guo, F., Xie, S., Wang, E., Wu, Y., Jiang, Z. et al. (2022). Mining‐induced failure characteristics and surrounding rock control of gob‐side entry driving adjacent to filling working face in the deep coal mine. Energy Science & Engineering, 10 (8), 2593–2611. doi: https://doi.org/10.1002/ese3.1214

- Shashenko, A. N., Pustovoytenko, V. P., Sdvizhikova, E. A. (2016). Geomekhanika. Kyiv: Novyy druk, 528.

- Nasonov, I. D. (1978). Modelirovanie gornyh protsessov. Moscow: Nedra, 256.

- Podkopaev, S. V., Gavrish, N. N., Deglin, B. M., Kamenets, V. I., Zinchenko, S. A. (2012). Laboratornyĭ praktikum po kursu «Mekhanika gornyh porod». Donetsk: DonNTU.

- Bachurin, L. L., Iordanov, I. V., Simonova, Yu. I., Korol, A. V., Podkopayev, Ye. S., Kayun, O. P. (2020). Experimental studies of the deformation characteristics of filling massifs. Technical Engineering, 2 (86), 136–149. doi: https://doi.org/10.26642/ten-2020-2(86)-136-149

- Ishibashi, I., Hazarika, H. (2015). Soil Mechanics Fundamentals and Applications. CRC Press, 432. doi: https://doi.org/10.1201/b18236

- Robitaille, V., Tremblay, D. (2001). Mécanique des sols: Théorie et pratique. Modulo.

- Demenko, V. (2009). Examples and Problems in Mechanics of Materials. Stress-Strain State at a Point of Elastic Deformable Solid. National Aerospace University “Kharkiv Aviation Institute”.

- Meshkov, Yu. Ya. (2001). The Concept of a Critical Density of Energy in Models of Fracture of Solids. Uspehi Fiziki Metallov, 2 (1), 7–50. doi: https://doi.org/10.15407/ufm.02.01.007

- Dekking, F. M., Kraaikamp, C., Lopuhaä, H. P., Meester, L. E. (2005). A Modern Introduction to Probability and Statistics. Springer London, 488. doi: https://doi.org/10.1007/1-84628-168-7

- Barkovskyi, V. V., Barkovska, N. V., Lopatin, O. K. (2002). Teoriya ymovirnostei ta matematychna statystyka. Kyiv: TsUL, 448.

##submission.downloads##

Опубліковано

Як цитувати

Номер

Розділ

Ліцензія

Авторське право (c) 2023 Oleksandr Tkachuk, Daria Chepiga, Serhii Pakhomov, Serhiy Volkov, Yaroslav Liashok, Yaroslava Bachurina, Iryna Shvets, Serhii Podkopaiev

Ця робота ліцензується відповідно до Creative Commons Attribution 4.0 International License.

Закріплення та умови передачі авторських прав (ідентифікація авторства) здійснюється у Ліцензійному договорі. Зокрема, автори залишають за собою право на авторство свого рукопису та передають журналу право першої публікації цієї роботи на умовах ліцензії Creative Commons CC BY. При цьому вони мають право укладати самостійно додаткові угоди, що стосуються неексклюзивного поширення роботи у тому вигляді, в якому вона була опублікована цим журналом, але за умови збереження посилання на першу публікацію статті в цьому журналі.

Ліцензійний договір – це документ, в якому автор гарантує, що володіє усіма авторськими правами на твір (рукопис, статтю, тощо).

Автори, підписуючи Ліцензійний договір з ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР», мають усі права на подальше використання свого твору за умови посилання на наше видання, в якому твір опублікований. Відповідно до умов Ліцензійного договору, Видавець ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР» не забирає ваші авторські права та отримує від авторів дозвіл на використання та розповсюдження публікації через світові наукові ресурси (власні електронні ресурси, наукометричні бази даних, репозитарії, бібліотеки тощо).

За відсутності підписаного Ліцензійного договору або за відсутністю вказаних в цьому договорі ідентифікаторів, що дають змогу ідентифікувати особу автора, редакція не має права працювати з рукописом.

Важливо пам’ятати, що існує і інший тип угоди між авторами та видавцями – коли авторські права передаються від авторів до видавця. В такому разі автори втрачають права власності на свій твір та не можуть його використовувати в будь-який спосіб.