Оптимальна абразивна зносостійкість епоксидних композитів, армованих відходами поліетилену (ПЕТ) з використанням конструкції Тагуті і нейронної мережі

DOI:

https://doi.org/10.15587/1729-4061.2023.272534Ключові слова:

епоксидні композити, відходи ПЕТ, абразивне зношування, Тагуті, штучна нейронна мережаАнотація

У роботі представлено дослідження трибологічних властивостей композитних матеріалів, розроблених на основі поліетилентерефталату (ПЕТ), який відіграє важливу роль у конструкціях машин, представлених трибологічними парами, виготовленими з композитних полімерів. У статті вивчено вплив двох факторів, а саме часу нагрівання перероблених відходів (HT) та масової частки (мас. %), на підвищення абразивної зносостійкості епоксидних композитів, армованих мікронаповнювачем.

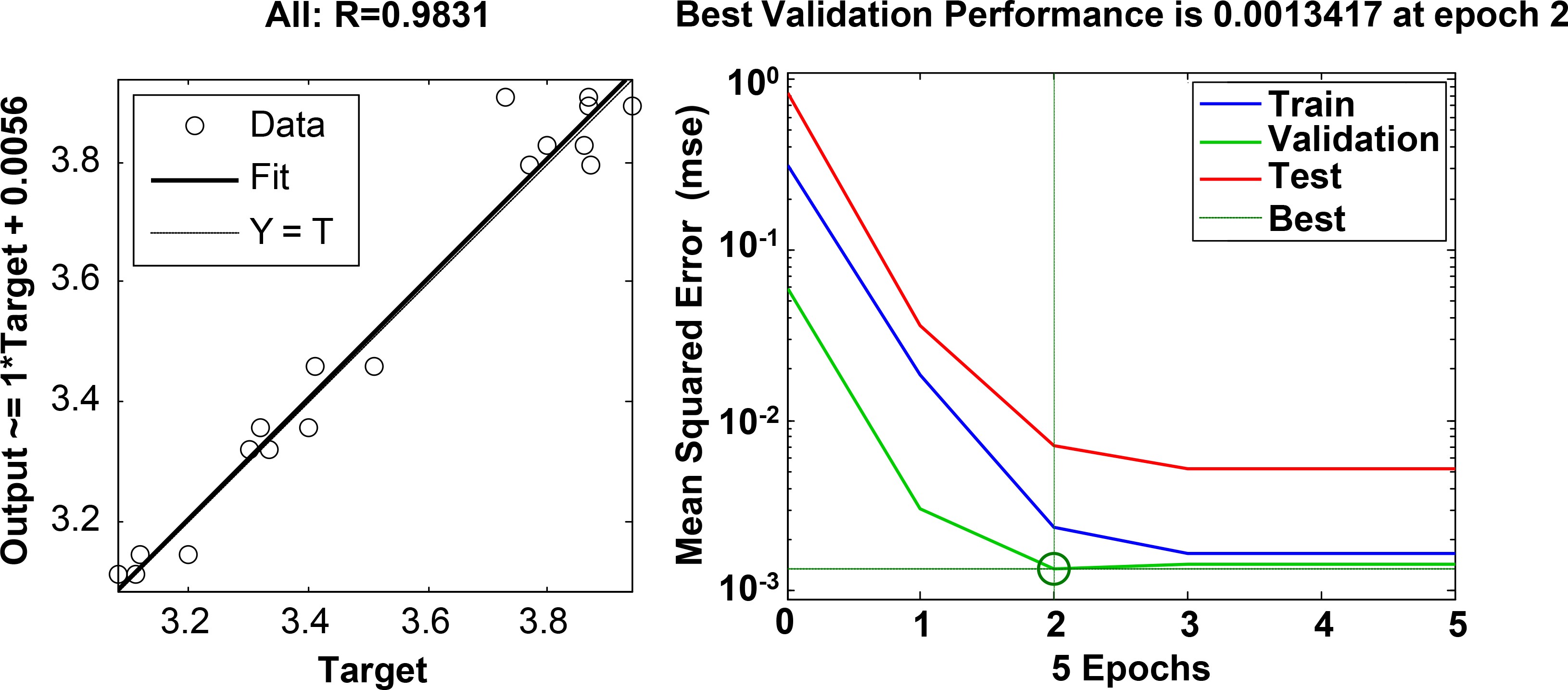

Метою даного дослідження є розробка епоксидних композитів з підвищеною абразивною зносостійкістю при забезпеченні низької вартості та ваги. Підвищення зносостійкості завдяки використанню епоксидних композитів для з'єднань, що працюють в умовах відсутності мастильного матеріалу в різних галузях промисловості, дозволить збільшити термін їхньої служби. Для визначення впливу параметрів HT та мас. % на швидкість зносу епоксидних композитів було проаналізовано відношення сигнал/шум. За допомогою програмного забезпечення MINITAB 19 були отримані рівняння регресії для кожної змінної для їхнього порівняння з результатами штучної нейронної мережі (ШНМ). Для прогнозування швидкості зносу епоксидних композитів на основі рівняння регресії та штучної нейронної мережі були розроблені прогностичні моделі. Для визначення найбільш ефективної моделі проведено порівняння їхніх результатів та виявлена найбільш підходяща модель з низькою похибкою. Результати дослідження показали поліпшення зносостійкості епоксидних композитів, армованих RCCF, на 41 % при збільшенні мас. % та HT, а також більш високу ефективність моделі ШНМ порівняно з регресійною моделлю для прогнозування швидкості зносу епоксидних композитів

Посилання

- Dudin, V., Makarenko, D., Derkach, O., Muranov, Y. (2021). Determination of the influence of a filler on the properties of composite materials based on polytetrafluorothylene for tribosystems of mechanisms and machines. Eastern-European Journal of Enterprise Technologies, 4 (12 (112)), 61–70. doi: https://doi.org/10.15587/1729-4061.2021.238452

- Ray, S. (2021). Parametric Optimization and Prediction of Abrasion Wear Behavior of Marble-Particle-Filled Glass–Epoxy Composites Using Taguchi Design Integrated with Neural Network. JOM, 73 (7), 2050–2059. doi: https://doi.org/10.1007/s11837-021-04698-8

- Singh, A. K., Bedi, R., Kaith, B. S. (2020). Mechanical properties of composite materials based on waste plastic – A review. Materials Today: Proceedings, 26, 1293–1301. doi: https://doi.org/10.1016/j.matpr.2020.02.258

- Karabork, F. (2022). Investigation of the mechanical, tribological and corrosive properties of epoxy composite coatings reinforced with recycled waste tire products. Express Polymer Letters, 16 (11), 1114–1127. doi: https://doi.org/10.3144/expresspolymlett.2022.82

- Sivaras, R., Sathishkumar, T. P., Naveenathakrishnan, P. (2019). Investigation on Tribological and Mechanical Properties of Filler Reinforeced Epoxy Composite. International Journal of Engineering Research & Technology (IJERT), 7 (2). Available at: https://www.ijert.org/research/investigation-on-tribological-and-mechanical-properties-of-filler-reinforeced-epoxy-composite-IJERTCONV7IS02019.pdf

- Wojciechowski, Ł., Sydow, Z., Bula, K., Gapiński, B. (2023). Friction and wear of polypropylene-based composites reinforced with cherry seed powder. Tribology International, 179, 108177. doi: https://doi.org/10.1016/j.triboint.2022.108177

- Tian, J., Qi, X., Li, C., Xian, G. (2023). Friction behaviors and wear mechanisms of multi-filler reinforced epoxy composites under dry and wet conditions: Effects of loads, sliding speeds, temperatures, water lubrication. Tribology International, 179, 108148. doi: https://doi.org/10.1016/j.triboint.2022.108148

- Khalaf, A. A., Abed, S. A., Alkhfaji, S. S., Al-Obaidi, M. A., Hanon, M. M. (2022). The effect of adding natural materials waste on the mechanical properties and water absorption of epoxy composite using grey relations analysis. EUREKA: Physics and Engineering, 1, 131–142. doi: https://doi.org/10.21303/2461-4262.2022.001952

- Abed, S. A., Khalaf, A. A., Shaalan, T. G. (2020). Experiential Analysis of Mechanical Properties and Strain Energy of Epoxy/Micro Filler Cu-Ni Composite. Journal of Mechanical Engineering Research and Developments, 43(1), 143–150. Available at: https://jmerd.net/Paper/Vol.43,No.1(2020)/143-150.pdf

- Abed, S. A., Khalaf, A. A., Mnati, H. M., Hanon, M. M. (2022). Optimization of mechanical properties of recycled polyurethane waste microfiller epoxy composites using grey relational analysis and taguchi method. Eastern-European Journal of Enterprise Technologies, 1 (12 (115)), 48–58. doi: https://doi.org/10.15587/1729-4061.2022.252719

- Toth, L. F., Szebenyi, G., Sukumaran, J., De Baets, P. (2021). Tribological characterization of nanoparticle filled PTFE: Wear-induced crystallinity increase and filler accumulation. Express Polymer Letters, 15 (10), 972–986. doi: https://doi.org/10.3144/expresspolymlett.2021.78

- Imani, A., Zhang, H., Owais, M., Zhao, J., Chu, P., Yang, J., Zhang, Z. (2018). Wear and friction of epoxy based nanocomposites with silica nanoparticles and wax-containing microcapsules. Composites Part A: Applied Science and Manufacturing, 107, 607–615. doi: https://doi.org/10.1016/j.compositesa.2018.01.033

##submission.downloads##

Опубліковано

Як цитувати

Номер

Розділ

Ліцензія

Авторське право (c) 2023 Salwa A. Abed, Ahmad A. Khalaf, Muzher Taha Mohamed, Muammel M. Hanon

Ця робота ліцензується відповідно до Creative Commons Attribution 4.0 International License.

Закріплення та умови передачі авторських прав (ідентифікація авторства) здійснюється у Ліцензійному договорі. Зокрема, автори залишають за собою право на авторство свого рукопису та передають журналу право першої публікації цієї роботи на умовах ліцензії Creative Commons CC BY. При цьому вони мають право укладати самостійно додаткові угоди, що стосуються неексклюзивного поширення роботи у тому вигляді, в якому вона була опублікована цим журналом, але за умови збереження посилання на першу публікацію статті в цьому журналі.

Ліцензійний договір – це документ, в якому автор гарантує, що володіє усіма авторськими правами на твір (рукопис, статтю, тощо).

Автори, підписуючи Ліцензійний договір з ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР», мають усі права на подальше використання свого твору за умови посилання на наше видання, в якому твір опублікований. Відповідно до умов Ліцензійного договору, Видавець ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР» не забирає ваші авторські права та отримує від авторів дозвіл на використання та розповсюдження публікації через світові наукові ресурси (власні електронні ресурси, наукометричні бази даних, репозитарії, бібліотеки тощо).

За відсутності підписаного Ліцензійного договору або за відсутністю вказаних в цьому договорі ідентифікаторів, що дають змогу ідентифікувати особу автора, редакція не має права працювати з рукописом.

Важливо пам’ятати, що існує і інший тип угоди між авторами та видавцями – коли авторські права передаються від авторів до видавця. В такому разі автори втрачають права власності на свій твір та не можуть його використовувати в будь-який спосіб.