Analysis of the thermal characteristics of the paraffin wax/high-density polyethylene (HDPE) composite as a form-stable phase change material (FSPCM) for thermal energy storage

DOI:

https://doi.org/10.15587/1729-4061.2023.273437Keywords:

charging, discharging, latent heat, paraffin, PCM, polymer, supercooling, thermal storageAbstract

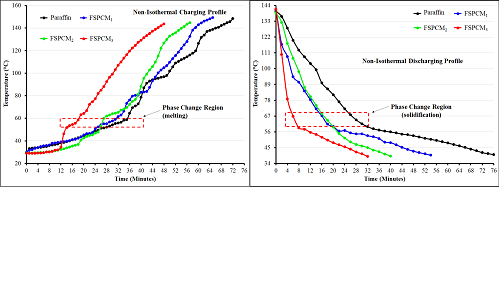

The present work is specifically focused on the form stability of paraffin as a phase change material (PCM) through the addition of high-density polyethylene (HDPE). The aim of adding HDPE is to obtain a stable form of paraffin during the phase transition. Moreover, improving the performance of PCM leads to an advanced operation of the latent heat storage unit with an excellent charging duration and response time. The study uses HDPE at a ratio of 5 wt %, 10 wt % and 15 wt %. The results indicate significant differences between the form-stable PCM (FSPCM) and pure paraffin. For instance, the supercooling degree is decreased with the addition of HDPE, where paraffin has a supercooling degree of 8.01 °C while FSPCM with 15 wt % HDPE has a supercooling degree of 3.73 °C. The latent heat of fusion by adding 10 wt % and 15 wt % HDPE is slightly decreased by 1.85 %, which is much lower compared to adding 5 wt % HDPE, which reduces the latent heat of fusion by about 6.02 %. Adding HDPE leads to a faster charging process and a better response time during the discharging process. The charging rate is increased significantly by adding 15 wt % HDPE with a substantial increment of around 40 % with an average charging rate of 2.39 °C/min. The heat release during the discharging process is increased for FSPCM with 5 wt % HDPE where the temperature drops by more than 70 °C within 20 minutes. The findings indicate that adding HDPE contributed positively to reducing the supercooling degree and providing a steady phase transition. Thus, the heat exchange process of paraffin is more favorable, which improves the performance of the latent heat storage unit. Furthermore, the operation can be improved significantly by providing a faster charging and discharging process

Supporting Agency

- The authors were grateful to The Ministry of Education, Culture, Research, and Technology the Republic of Indonesia as being the funder of research under scheme Penelitian Dasar Unggulan Perguruan Tinggi 2022 and Reza Abdu Rahman from Universitas Pancasila for supporting the study

References

- Ismail, I., Mulyanto, A. T., Rahman, R. A. (2022). Development of free water knock-out tank by using internal heat exchanger for heavy crude oil. EUREKA: Physics and Engineering, 4, 77–85. doi: https://doi.org/10.21303/2461-4262.2022.002502

- Ismail, I., John, J., Pane, E. A., Maulana, R., Rahman, R. A., Suwandi, A. (2021). Experimental Evaluation for The Feasibility of Test Chamber in The Open-Loop Wind Tunnel. WSEAS transactions on fluid mechanics, 16, 120–126. doi: https://doi.org/10.37394/232013.2021.16.12

- Ismail, I., Pane, E. A., Haryanto, G., Okviyanto, T., Rahman, R. A. (2021). A Better Approach for Modified Bach-Type Savonius Turbine Optimization. International Review of Aerospace Engineering (IREASE), 14 (3), 159. doi: https://doi.org/10.15866/irease.v14i3.20612

- Hu, M., Yan, Z., Peng, L., Guo, N., Liu, Z. (2019). Optimization of preparation and analysis of Paraffin/SiO2 composite PCMs via sol-gel method. IOP Conference Series: Earth and Environmental Science, 242, 032005. doi: https://doi.org/10.1088/1755-1315/242/3/032005

- Innovation Outlook: Thermal Energy Storage. IRENA. Available at: https://www.irena.org/publications/2020/Nov/Innovation-outlook-Thermal-energy-storage

- Rahmalina, D., Adhitya, D. C., Rahman, R. A., Ismail, I. (2021). Improvement the performance of composite PCM paraffin-based incorporate with volcanic ash as heat storage for low-temperature application. EUREKA: Physics and Engineering, 1, 53–61. doi: https://doi.org/10.21303/2461-4262.2022.002055

- Tunggul Ismail, A., Ismail, I., Abdu Rahman, R. (2022). Increasing the reliability of biomass solid fuel combustion using a combined regenerative heat exchanger as an indirect burner. Eastern-European Journal of Enterprise Technologies, 5 (8 (119)), 53–61. doi: https://doi.org/10.15587/1729-4061.2022.265803

- Khademi, A., Shank, K., Mehrjardi, S. A. A., Tiari, S., Sorrentino, G., Said, Z. et al. (2022). A brief review on different hybrid methods of enhancement within latent heat storage systems. Journal of Energy Storage, 54, 105362. doi: https://doi.org/10.1016/j.est.2022.105362

- Zhang, P., Meng, Z. N., Zhu, H., Wang, Y. L., Peng, S. P. (2017). Melting heat transfer characteristics of a composite phase change material fabricated by paraffin and metal foam. Applied Energy, 185, 1971–1983. doi: https://doi.org/10.1016/j.apenergy.2015.10.075

- Agarwal, A., Sarviya, R. M. (2017). Characterization of Commercial Grade Paraffin wax as Latent Heat Storage material for Solar dryers. Materials Today: Proceedings, 4 (2), 779–789. doi: https://doi.org/10.1016/j.matpr.2017.01.086

- Suyitno, B. M., Rahmalina, D., Rahman, R. A. (2023). Increasing the charge/discharge rate for phase-change materials by forming hybrid composite paraffin/ash for an effective thermal energy storage system. AIMS Materials Science, 10 (1), 70–85. doi: https://doi.org/10.3934/matersci.2023005

- Tang, Y., Su, D., Huang, X., Alva, G., Liu, L., Fang, G. (2016). Synthesis and thermal properties of the MA/HDPE composites with nano-additives as form-stable PCM with improved thermal conductivity. Applied Energy, 180, 116–129. doi: https://doi.org/10.1016/j.apenergy.2016.07.106

- Zhang, L., Dong, J. (2017). Experimental study on the thermal stability of a paraffin mixture with up to 10,000 thermal cycles. Thermal Science and Engineering Progress, 1, 78–87. doi: https://doi.org/10.1016/j.tsep.2017.02.005

- Rahman, R. A., Lahuri, A. H., Ismail (2023). Thermal stress influence on the long-term performance of fast-charging paraffin-based thermal storage. Thermal Science and Engineering Progress, 37, 101546. doi: https://doi.org/10.1016/j.tsep.2022.101546

- Gandhi, M., Kumar, A., Elangovan, R., Meena, C. S., Kulkarni, K. S., Kumar, A. et al. (2020). A Review on Shape-Stabilized Phase Change Materials for Latent Energy Storage in Buildings. Sustainability, 12 (22), 9481. doi: https://doi.org/10.3390/su12229481

- Chen, P., Gao, X., Wang, Y., Xu, T., Fang, Y., Zhang, Z. (2016). Metal foam embedded in SEBS/paraffin/HDPE form-stable PCMs for thermal energy storage. Solar Energy Materials and Solar Cells, 149, 60–65. doi: https://doi.org/10.1016/j.solmat.2015.12.041

- Sciacovelli, A., Navarro, M. E., Jin, Y., Qiao, G., Zheng, L., Leng, G. et al. (2018). High density polyethylene (HDPE) – Graphite composite manufactured by extrusion: A novel way to fabricate phase change materials for thermal energy storage. Particuology, 40, 131–140. doi: https://doi.org/10.1016/j.partic.2017.11.011

- Wu, M. Q., Wu, S., Cai, Y. F., Wang, R. Z., Li, T. X. (2021). Form-stable phase change composites: Preparation, performance, and applications for thermal energy conversion, storage and management. Energy Storage Materials, 42, 380–417. doi: https://doi.org/10.1016/j.ensm.2021.07.019

- Rahmalina, D., Rahman, R. A., Ismail (2022). Increasing the rating performance of paraffin up to 5000 cycles for active latent heat storage by adding high-density polyethylene to form shape-stabilized phase change material. Journal of Energy Storage, 46, 103762. doi: https://doi.org/10.1016/j.est.2021.103762

- Gibb, D., Seitz, A., Johnson, M., Romani, J., Gasia, J., Cabeza, L. F. et al. (2018). Applications of Thermal Energy Storage in the Energy Transition. IEA-ECES. Available at: https://iea-es.org/wp-content/uploads/public/Applications-of-Thermal-Energy-Storage-in-the-Energy-Trenasition-Annex-30_Public-Report.pdf

- Majewski, K., Mantell, S. C., Bhattacharya, M. (2020). Relationship between morphological changes and mechanical properties in HDPE films exposed to a chlorinated environment. Polymer Degradation and Stability, 171, 109027. doi: https://doi.org/10.1016/j.polymdegradstab.2019.109027

- Safari, A., Saidur, R., Sulaiman, F. A., Xu, Y., Dong, J. (2017). A review on supercooling of Phase Change Materials in thermal energy storage systems. Renewable and Sustainable Energy Reviews, 70, 905–919. doi: https://doi.org/10.1016/j.rser.2016.11.272

- Antar, E., Elkhoury, M. (2019). Parametric sizing optimization process of a casing for a Savonius Vertical Axis Wind Turbine. Renewable Energy, 136, 127–138. doi: https://doi.org/10.1016/j.renene.2018.12.092

- Sivapalan, B., Neelesh Chandran, M., Manikandan, S., Saranprabhu, M. K., Pavithra, S., Rajan, K. S. (2018). Paraffin wax–water nanoemulsion: A superior thermal energy storage medium providing higher rate of thermal energy storage per unit heat exchanger volume than water and paraffin wax. Energy Conversion and Management, 162, 109–117. doi: https://doi.org/10.1016/j.enconman.2018.01.073

- Deng, Z., Li, J., Zhang, X., Yao, F., Shen, C. (2020). Melting intensification in a horizontal latent heat storage (LHS) system using a paraffin / fractal metal matrices composite. Journal of Energy Storage, 32, 101857. doi: https://doi.org/10.1016/j.est.2020.101857

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Dwi Rahmalina, Almira Rahma Zada, Herni Soefihandini, Ismail, Budhi Muliawan Suyitno

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.