Determining forces arising during the passage of cotton fiber between the fixed knife and working drum of the roller gin

DOI:

https://doi.org/10.15587/1729-4061.2023.273490Keywords:

roller gin, working roller, fixed knife of roller gin, breaking organ, drum designAbstract

The object of this study is a roller gin. Roller gins are installed in the gin shops of cotton factories and their purpose is to mechanically separate cotton fiber from seeds in fine-fiber varieties of cotton. The criteria for the technological evaluation of roller gin are the sum of defects and fiber contamination after ginning, the cleansing effect of gin on weeds, damage to seeds, and fiber tow effects.

Existing methods do not fully reveal all the reserves of increasing the productivity of the machine, improving the design of the main working bodies of the roller gin, ensuring the effective operation of the machine, and preserving the natural qualities of fiber and seeds.

The determination of the force on the surface of the drum during the ginning process is of great practical interest for designing main working bodies of roller gins.

The efficiency and quality of the processed product depend on the interaction of the working drum and knife with the breaking organ in the process of fiber separation. The design of the drum and knife, their kinematic parameters, the stability of technological wiring largely determine both the performance of the gin and the quality of the fiber and seeds.

Theoretical studies have been conducted to determine the factors that affect the performance of roller gin. Based on the results obtained, it is recommended to change the most important structural parameters of the machine.

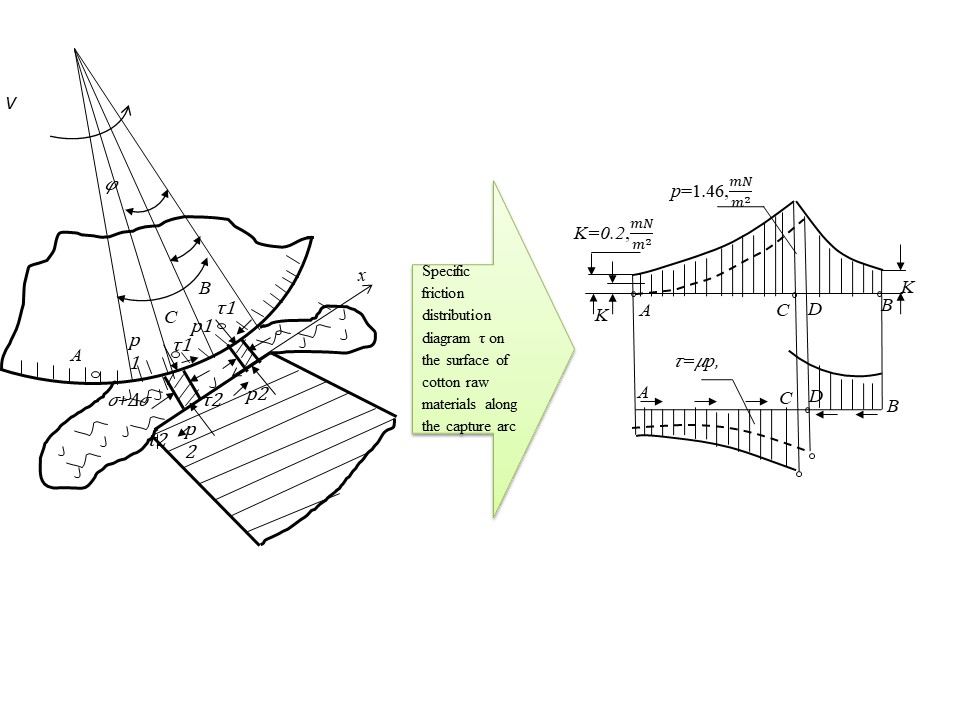

The obtained analytical expressions for the specific pressure and specific friction forces applied from the side of the drum surface to the processed mass of raw materials make it possible to conclude that when the load from the breaking body increases during the lower rebound, the process of grasping, dragging, and holding the fibers between the working drum and the fixed knife worsens

References

- Zul'fanov, S. Z., Safarov, F. M., Rudovskiy, P. N. (2014). Vliyaniya fiziko – mekhanicheskikh svoystv khlopka i tekhnologiya ego pererabotki na proizvoditel'nost' valichnogo dzhina. Vestnik Tadzhikskogo tekhnicheskogo universiteta im. akad. M. S. Osimi, 2 (26), 16–19. Available at: https://e.lanbook.com/journal/issue/294066

- Khafizov, I. K. (2007). Noviy material rabochego valika. Khlopkovaya promyshlennost', 4, 15–16.

- Tursunov, Kh. K. (1990). Issledovanie vliyaniya proizvoditel'nosti valichnykh dzhinov na produkty pererabotki semennogo tonkovoloknistogo khlopka selektsii T-14. Khlopkovaya promyshlennost', 6, 16–19.

- Armijo, C. B., Whitelock, D. P., Thomas, J. W., Hughs, S. E., Gillum, M. N. (2017). COTTON GINNERS HANDBOOK: Roller Ginning. Journal of Cotton Science, 21 (3), 199–209. doi: https://doi.org/10.56454/vmim5000

- Hosseinali, F., Thomasson, J. (2018). Multiscale Frictional Properties of Cotton Fibers: A Review. Fibers, 6 (3), 49. doi: https://doi.org/10.3390/fib6030049

- Alkhateeb, W. J. (2020). Response surface optimization of cotton tufts opening degree using Box–Behnken designs. International Journal of Clothing Science and Technology, 33 (2), 254–269. https://doi.org/10.1108/ijcst-11-2019-0165

- Usmanov, D., Umarova, M. (2022). The process of cotton raw fine-fiber ginning. Universum: Technical Sciences, 4 (97). Available at: https://7universum.com/pdf/tech/4(97)%20[15.04.2022]/Usmanov.pdf

- Miroshnichenko, G. I., Korabel'nikov, R. V., Yakubov, D. Ya. (1992). Issledovanie plotnosti rabochego valika valichnogo dzhina i ee vliyaniya na usilie zatyagivaniya za nozh. Khlopkovaya promyshlennost', 2, 7–8.

- Iyer, E. V. G. (2021). Evaluating Gin Roller Covering Materials for Cotton Double Roller Gins for the Sustainable Communication, Media, Society and Culture. Journal of Emerging Trends in Engineering and Applied Sciences, 12, 142. Available at: https://www.worldcat.org/title/9664818815

- Korabel'nikov, R. V., Ibrogimov, Kh. I. (2009). Osnovy protsessa zazhguchivaniya voloknistykh svyazey chastits khlopka-syrtsa pri netsentral'nom udare kolkov. Izvestiya VUZov. Tekhnologiya tekstil'noy promyshlennosti, 4 (318), 23–28. Available at: https://ttp.ivgpu.com/wp-content/uploads/2015/11/318_6.pdf

- Turakhonov, Kh. Kh. (1991). Issledovanie vliyaniya konstruktivnykh parametrov otboynogo organa na tekhnologicheskie pokazateli raboty valichnogo dzhina. Khlopkovaya promyshlennost', 3, 14–15.

- Hosseinali, Thomasson. (2019). Probing of Nanoscale Friction and Mechanical Characteristics of Cotton Fiber’s Surface. Fibers, 7 (7), 64. doi: https://doi.org/10.3390/fib7070064

- Akramov, A. (1982). Vliyanie ulyuchnoy kanavki na kachestvo volokna i semyan pri valichnom dzhinirovanii. Khlopkovaya promyshlennost', 3, 4–5.

- Khakimov, S., Makxammadiyev, Z., Khadjayeva, M. (2022). Study of durability of the clear grooves of the working drum of the roller jin. Universum: Technical Sciences, 3 (96). doi: https://doi.org/10.32743/unitech.2022.96.3.13300

- Safarov, F. M., Korabel'nikov, R. V. (2006). Optimizatsiya rezhimov dzhinirovaniya novogo selektsionnogo sorta dlinnovoloknistogo khlopka 9326-V. Izvestiya Vuzov. Tekhnologiya tekstil'noy promyshlennosti, 5 (293), 49–51. Available at: https://ttp.ivgpu.com/wp-content/uploads/2015/12/293_13.pdf

- Kudratov, O. O. (1992). Issledovaniya zhestkosti sistemy rabochego valika nepodvizhnogo nozha valichnogo dzhina i ee vliyanie na nadezhnost' protsessa. Khlopkovaya promyshlennost', 3, 14–15.

- Miroshnichenko, G. I. (1972). Osnovy proektirovaniya mashin pervichnoy obrabotki khlopka. Moscow: Mashinostroenie, 486.

- Ibrogimov, Kh. I., Korabel'nikov, R. V. (2009). Parametry dvizheniya chastits khlopka-syrtsa po poverkhnosti kolkov v ochistitelyakh melkogo sora. Izvestiya Vuzov. Tekhnologiya tekstil'noy promyshlennosti, 1 (313), 34–36. Available at: https://ttp.ivgpu.com/wp-content/uploads/2015/11/313_10.pdf

- Il'yushin, A. A. (1963). Plastichnost'. Osnovy obschey matematicheskoy teorii. Moscow: Izd-vo AN SSSR, 271.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Fazil Veliev

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.