Development of Bi-hexagonal hybrid crash box subjected to axial loading for enhancement of crashworthiness

DOI:

https://doi.org/10.15587/1729-4061.2023.273847Keywords:

Bi-hexagonal hybrid crash box, energy absorption, deformation pattern, axial loadingAbstract

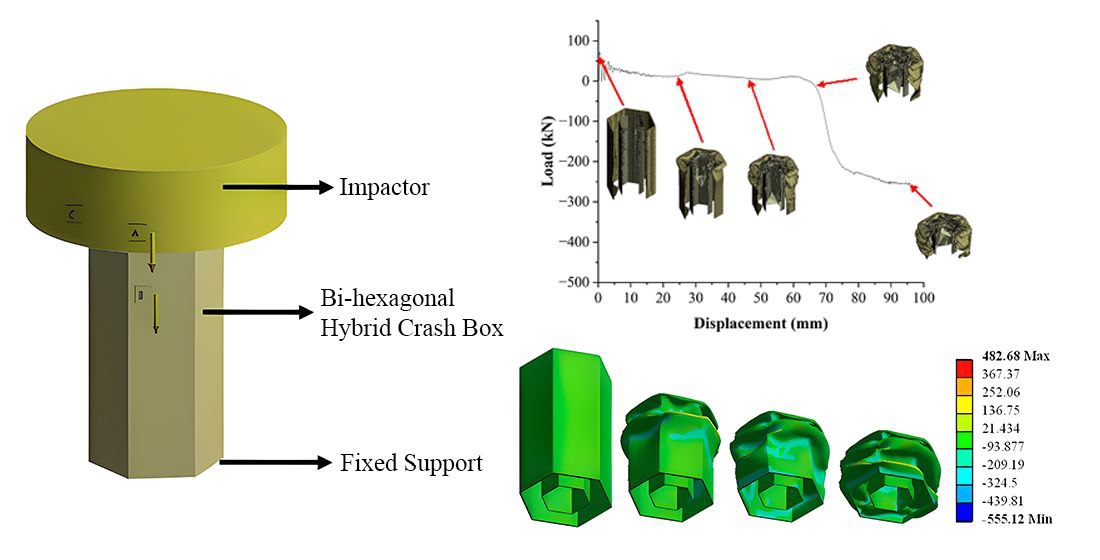

Crash box design had been developed to increase crashwortiness performance. The crash box cross section is one important parameter to increase the energy absorption as crashwortiness performance. In the previous study, hexagonal cross section provide the higher energy absorption than other cross section. One of strategy to increase cross section is using two cross section put together in one component of crash box design. Bi-tubular crash box shows higher energy absorption with easy manufacture opportunity. In other study, hybrid crash box is investigated to reduce crash box mass. In this study, development of bi-hexagonal hybrid crash box subjected to axial loading to enhance crashworthiness were investigated. Analysis of crash box design is developed by using computer simulation with ANSYS Workbench 19.2. The crash box materials used are Aluminum Alloy and carbon-epoxy woven. The material modeling in the crash box is assumed as deformable body while the impactor is a rigid body. The axial loading is modelled by setting impactor impact the crash box with a speed of 7.67 m/s. Fixed support is set on the bottom of crash box. Nine of frontal test models were simulated for the bi-hexagonal hybrid crash box with different layups orientation angle and composite hexagonal tube diameter. Energy absorption and deformation patterns were observed. The results indicated that the highest energy absorption and specific energy absorption is occured on the A60 model with layups orientation angle of [0/60/0/60] and composite hexagonal tube diameter of 41 mm are 3693.8 J and 19.121 kJ/kg. The deformation pattern in the aluminum part is diamond mode, while in the composite part, the deformation pattern produce transverse shearing, lamina bending, brittle fracturing and local buckling mode

Supporting Agency

- This study was supported by Professor Accelerated Grant from Engineering Faculty, Brawijaya University, Malang, Indonesia. We also thank Design and System Engineering laboratory, Mechanical Engineering Department, Brawijaya University for providing ANSYS Research license.

References

- Kokkula, S., Langseth, M., Hopperstad, O. S., Lademo, O. G. (2006). Behaviour of an automotive bumper beam-longitudinal system at 40% offset impact: An experimental and numerical study. Latin American Journal of Solids and Structures, 3, 59–73. Available at: https://www.lajss.org/index.php/LAJSS/article/view/90/84

- Ma, J. (2011). Thin-walled Tubes with Pre-folded Origami Patterns as Energy Absorption Devices. University of Oxford, 212. Available at: https://eng.ox.ac.uk/media/8615/ma.pdf

- Jandaghi Shahi, V., Marzbanrad, J. (2012). Analytical and experimental studies on quasi-static axial crush behavior of thin-walled tailor-made aluminum tubes. Thin-Walled Structures, 60, 24–37. doi: https://doi.org/10.1016/j.tws.2012.05.015

- Tarlochan, F., Samer, F., Hamouda, A. M. S., Ramesh, S., Khalid, K. (2013). Design of thin wall structures for energy absorption applications: Enhancement of crashworthiness due to axial and oblique impact forces. Thin-Walled Structures, 71, 7–17. doi: https://doi.org/10.1016/j.tws.2013.04.003

- Choiron, M. A. (2020). Analysis of multi-cell hexagonal crash box design with foam filled under frontal load model. Journal of Physics: Conference Series, 1446 (1), 012022. doi: https://doi.org/10.1088/1742-6596/1446/1/012022

- Qiu, N., Gao, Y., Fang, J., Feng, Z., Sun, G., Li, Q. (2016). Theoretical prediction and optimization of multi-cell hexagonal tubes under axial crashing. Thin-Walled Structures, 102, 111–121. doi: https://doi.org/10.1016/j.tws.2016.01.023

- Choiron, M. A. (2020). Characteristics of deformation pattern and energy absorption in honeycomb filler crash box due to frontal load and oblique load test. Eastern-European Journal of Enterprise Technologies, 2 (7 (104)), 6–11. doi: https://doi.org/10.15587/1729-4061.2020.200020

- Zhu, G., Sun, G., Yu, H., Li, S., Li, Q. (2018). Energy absorption of metal, composite and metal/composite hybrid structures under oblique crushing loading. International Journal of Mechanical Sciences, 135, 458–483. doi: https://doi.org/10.1016/j.ijmecsci.2017.11.017

- Alavi Nia, A., Parsapour, M. (2014). Comparative analysis of energy absorption capacity of simple and multi-cell thin-walled tubes with triangular, square, hexagonal and octagonal sections. Thin-Walled Structures, 74, 155–165. doi: https://doi.org/10.1016/j.tws.2013.10.005

- Bai, Z., Guo, H., Jiang, B., Zhu, F., Cao, L. (2014). A study on the mean crushing strength of hexagonal multi-cell thin-walled structures. Thin-Walled Structures, 80, 38–45. doi: https://doi.org/10.1016/j.tws.2014.02.024

- Vimal Kannan, I., Rajkumar, R. (2019). Deformation and energy absorption analysis of simple and multi-cell thin-walled tubes under quasi-static axial crushing. International Journal of Crashworthiness, 25 (2), 121–130. doi: https://doi.org/10.1080/13588265.2018.1542956

- Velmurugan, R., Muralikannan, R. (2009). Energy Absorption Characteristics of Annealed Steel Tubes of Various Cross Sections in Static and Dynamic Loading. Latin American Journal of Solid and Structures, 6 (4), 385–412. Available at: https://www.lajss.org/index.php/LAJSS/article/view/232/202

- Zhao, X., Zhu, G., Zhou, C., Yu, Q. (2019). Crashworthiness analysis and design of composite tapered tubes under multiple load cases. Composite Structures, 222, 110920. doi: https://doi.org/10.1016/j.compstruct.2019.110920

- Choirotin, I., Choiron, M. A., Purnowidodo, A., Darmadi, D. B. (2021). Deformation Mode and Energy Absorption Analysis of Bi-Tubular Corrugated Crash Box Structure. International Journal of Integrated Engineering, 13 (7), 274–280. Available at: https://publisher.uthm.edu.my/ojs/index.php/ijie/article/view/7928

- Praveen Kumar, A., Nageswara Rao, D. (2021). Crushing characteristics of double circular composite tube structures subjected to axial impact loading. Materials Today: Proceedings, 47, 5923–5927. doi: https://doi.org/10.1016/j.matpr.2021.04.465

- Boria, S., Scattina, A., Belingardi, G. (2018). Axial Crushing of Metal-Composite Hybrid Tubes: Experimental Analysis. Procedia Structural Integrity, 8, 102–117. doi: https://doi.org/10.1016/j.prostr.2017.12.012

- Obradovic, J., Boria, S., Belingardi, G. (2012). Lightweight design and crash analysis of composite frontal impact energy absorbing structures. Composite Structures, 94 (2), 423–430. doi: https://doi.org/10.1016/j.compstruct.2011.08.005

- Sharifi, S., Shakeri, M., Fakhari, H. E., Bodaghi, M. (2015). Experimental investigation of bitubal circular energy absorbers under quasi-static axial load. Thin-Walled Structures, 89, 42–53. doi: https://doi.org/10.1016/j.tws.2014.12.008

- Esnaola, A., Elguezabal, B., Aurrekoetxea, J., Gallego, I., Ulacia, I. (2016). Optimization of the semi-hexagonal geometry of a composite crush structure by finite element analysis. Composites Part B: Engineering, 93, 56–66. doi: https://doi.org/10.1016/j.compositesb.2016.03.002

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Moch Agus Choiron, Delia Hani Wakhidah, Nurchajat

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.