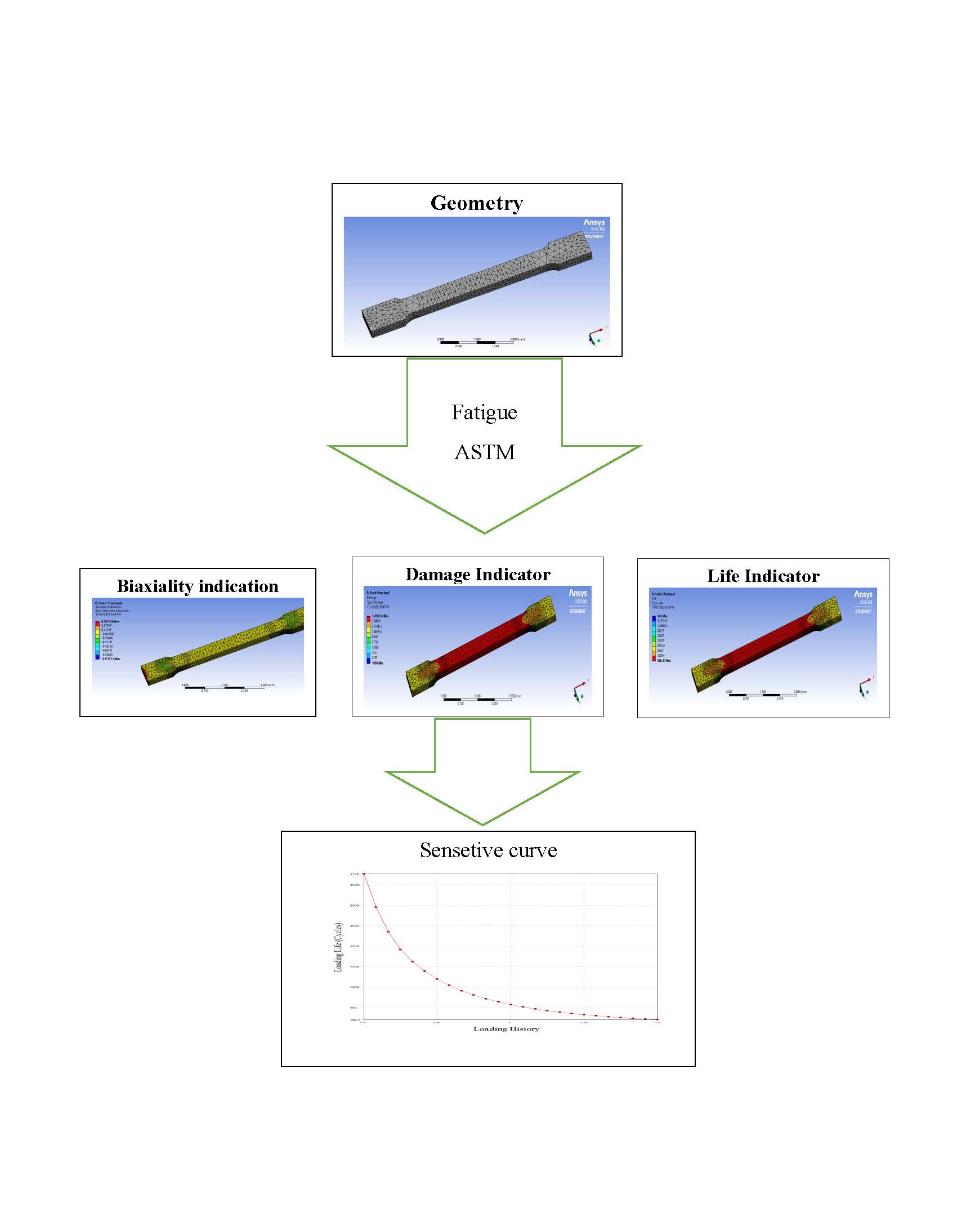

Визначення втоми композитної структури kenaf/PLA за допомогою втомного зразка (ASTM D7791): обчислювальний аналіз

DOI:

https://doi.org/10.15587/1729-4061.2023.273974Ключові слова:

Статичні конструкції, FEM, аналіз втоми, kenaf/PLA композит, ASTM D7791Анотація

У цьому дослідженні зразок композиту kenaf/PLA піддавався втомному навантаженню, а результати аналізувалися чисельно. Деякі з найбільш важливих аспектів інструменту для вимірювання втоми, які розглядалися, були очікувана тривалість життя, пошкодження, альтернативне навантаження та індикація двовісності. Статичний структурний інструмент використовувався для прогнозування числового аналізу, а розрахунки проводилися за теорією втоми Гудмана. Навантаження повністю змінили так, щоб воно дорівнювало 30 кН, коли було виявлено, що система може продовжувати функціонувати навіть після завершення циклів 1e6. Після застосування альтернативного навантаження 30 кН показник двовісності був встановлений як 0,425, з мінімальним значенням 0,9. Встановлено розмір завданих збитків. Мінімальна кількість циклів, необхідних для досягнення максимального потенціалу шкоди, становить 1000, а максимальна кількість циклів, необхідних для досягнення максимального потенціалу шкоди, становить 1,7662·106. Встановлено, що існує інший стрес, який можна порівняти з цим. На підставі результатів дослідження було встановлено, що галтельні ділянки зразка піддавалися максимальній альтернативній напрузі 716,4 МПа. Альтернативне напруження не може опускатися нижче 31,276 МПа ні за яких обставин. Підрахунком встановлено, що загалом на життя було витрачено 106 циклів. Було виявлено, що не буде жодних пошкоджень незалежно від кількості циклів, які проходять через те, що це число дорівнює 1. Було встановлено, що альтернативне напруження може досягати максимального значення 716,4 МПа, таке що було значенням, яке використовувалося для альтернативного порівняння.

Посилання

- Shahar, F. S., Hameed Sultan, M. T., Safri, S. N. A., Jawaid, M., Abu Talib, Abd. R., Basri, A. A., Md Shah, A. U. (2022). Fatigue and impact properties of 3D printed PLA reinforced with kenaf particles. Journal of Materials Research and Technology, 16, 461–470. doi: https://doi.org/10.1016/j.jmrt.2021.12.023

- Travieso-Rodriguez, J. A., Zandi, M. D., Jerez-Mesa, R., Lluma-Fuentes, J. (2020). Fatigue behavior of PLA-wood composite manufactured by fused filament fabrication. Journal of Materials Research and Technology, 9 (4), 8507–8516. doi: https://doi.org/10.1016/j.jmrt.2020.06.003

- Shahar, F. S., Hameed Sultan, M. T., Safri, S. N. A., Jawaid, M., Abu Talib, Abd. R., Basri, A. A., Md Shah, A. U. (2022). Physical, thermal and tensile behaviour of 3D printed kenaf/PLA to suggest its usability for ankle–foot orthosis – a preliminary study. Rapid Prototyping Journal, 28 (8), 1573–1588. doi: https://doi.org/10.1108/rpj-08-2021-0207

- Beigpour, R., Shokrollahi, H., Khalili, S. M. R. (2021). Experimental and numerical analysis of a biodegradable hybrid composite under tensile and three-point bending tests. Composite Structures, 273, 114255. doi: https://doi.org/10.1016/j.compstruct.2021.114255

- Azlin, M. N. M., Sapuan, S. M., Zuhri, M. Y. M., Zainudin, E. S. (2022). Effect of stacking sequence and fiber content on mechanical and morphological properties of woven kenaf/polyester fiber reinforced polylactic acid (PLA) hybrid laminated composites. Journal of Materials Research and Technology, 16, 1190–1201. doi: https://doi.org/10.1016/j.jmrt.2021.12.046

- Nurazzi, N. M., Shazleen, S. S., Aisyah, H. A., Asyraf, M. R. M., Sabaruddin, F. A., Mohidem, N. A. et al. (2021). Effect of silane treatments on mechanical performance of kenaf fibre reinforced polymer composites: a review. Functional Composites and Structures, 3 (4), 045003. doi: https://doi.org/10.1088/2631-6331/ac351b

- Samat, N., Sulaiman, M. A., Ahmad, Z., Anuar, H. (2021). A comparative study on the desiccant effect of polypropylene and polylactic acid composites reinforced with different lignocellulosic fibres. Journal of Applied Science and Engineering, 24 (2), 223–231. doi: https://doi.org/10.6180/jase.202104_24(2).0011

- Lee, C. H., Padzil, F. N. B. M., Lee, S. H., Ainun, Z. M. A., Abdullah, L. C. (2021). Potential for Natural Fiber Reinforcement in PLA Polymer Filaments for Fused Deposition Modeling (FDM) Additive Manufacturing: A Review. Polymers, 13 (9), 1407. doi: https://doi.org/10.3390/polym13091407

- Radzuan, N. A. M., Tholibon, D., Sulong, A. B., Muhamad, N., Haron, C. H. C. (2020). New processing technique for biodegradable kenaf composites: A simple alternative to commercial automotive parts. Composites Part B: Engineering, 184, 107644. doi: https://doi.org/10.1016/j.compositesb.2019.107644

- Nor Arman, N. S., Chen, R. S., Ahmad, S. (2021). Review of state-of-the-art studies on the water absorption capacity of agricultural fiber-reinforced polymer composites for sustainable construction. Construction and Building Materials, 302, 124174. doi: https://doi.org/10.1016/j.conbuildmat.2021.124174

- Asim, M., Paridah, M. T., Chandrasekar, M., Shahroze, R. M., Jawaid, M., Nasir, M., Siakeng, R. (2020). Thermal stability of natural fibers and their polymer composites. Iranian Polymer Journal, 29 (7), 625–648. doi: https://doi.org/10.1007/s13726-020-00824-6

- Chandgude, S., Salunkhe, S. (2021). In state of art: Mechanical behavior of natural fiber‐based hybrid polymeric composites for application of automobile components. Polymer Composites, 42 (6), 2678–2703. doi: https://doi.org/10.1002/pc.26045

- Ilyas, R. A., Zuhri, M. Y. M., Aisyah, H. A., Asyraf, M. R. M., Hassan, S. A., Zainudin, E. S. et al. (2022). Natural Fiber-Reinforced Polylactic Acid, Polylactic Acid Blends and Their Composites for Advanced Applications. Polymers, 14 (1), 202. doi: https://doi.org/10.3390/polym14010202

- Senthil Muthu Kumar, T., Senthilkumar, K., Chandrasekar, M., Subramaniam, S., Mavinkere Rangappa, S., Siengchin, S., Rajini, N. (2020). Influence of Fillers on the Thermal and Mechanical Properties of Biocomposites: An Overview. Biofibers and Biopolymers for Biocomposites, 111–133. doi: https://doi.org/10.1007/978-3-030-40301-0_5

- Whitworth, A. H., Tsavdaridis, K. D. (2020). Genetic Algorithm for Embodied Energy Optimisation of Steel-Concrete Composite Beams. Sustainability, 12 (8), 3102. doi: https://doi.org/10.3390/su12083102

- Xiang, S., Wang, D., Yang, L., Tan, B. (2021). Study on the life cycle simulation method of the temperature field and temperature effect of a steel–concrete composite bridge deck system. Measurement and Control, 54 (5-6), 1068–1081. doi: https://doi.org/10.1177/00202940211020343

- Cheng, Z., Zhang, Q., Bao, Y., Deng, P., Wei, C., Li, M. (2021). Flexural behavior of corrugated steel-UHPC composite bridge decks. Engineering Structures, 246, 113066. doi: https://doi.org/10.1016/j.engstruct.2021.113066

- Ovuoba, B., Prinz, G. S. (2018). Investigation of residual fatigue life in shear studs of existing composite bridge girders following decades of traffic loading. Engineering Structures, 161, 134–145. doi: https://doi.org/10.1016/j.engstruct.2018.02.018

- Ferreira, F. P. V., Tsavdaridis, K. D., Martins, C. H., De Nardin, S. (2021). Steel-Concrete Composite Beams with Precast Hollow-Core Slabs: A Sustainable Solution. Sustainability, 13 (8), 4230. doi: https://doi.org/10.3390/su13084230

- Li, C., Lei, Z., Feng, Z., He, W., Tan, L. (2021). Research on static performance of lightweight STC-steel composite deck. J. Transp. Sci. Eng., 37, 26–33. doi: https://doi.org/10.16544/j.cnki.cn43-1494/u.2021.01.005

- Lee, P.-G., Shim, C.-S., Chang, S.-P. (2005). Static and fatigue behavior of large stud shear connectors for steel–concrete composite bridges. Journal of Constructional Steel Research, 61 (9), 1270–1285. doi: https://doi.org/10.1016/j.jcsr.2005.01.007

- Xu, X., Zhou, X., Liu, Y. (2020). Behavior of rubber-sleeved stud shear connectors under fatigue loading. Construction and Building Materials, 244, 118386. doi: https://doi.org/10.1016/j.conbuildmat.2020.118386

- Cao, J., Shao, X., Deng, L., Gan, Y. (2017). Static and Fatigue Behavior of Short-Headed Studs Embedded in a Thin Ultrahigh-Performance Concrete Layer. Journal of Bridge Engineering, 22 (5). doi: https://doi.org/10.1061/(asce)be.1943-5592.0001031

- Yang, D. (2021). Analysis of Fracture Mechanics Theory of the First Fracture Mechanism of Main Roof and Support Resistance with Large Mining Height in a Shallow Coal Seam. Sustainability, 13 (4), 1678. doi: https://doi.org/10.3390/su13041678

- Wang, Y., Nie, J. (2009). Fatigue behavior of studs in a composite beam based on fracture mechanics. Qinghua Daxue Xuebao/Journal of Tsinghua University, 49 (9), 1467–1470.

- Wu, X., Yu, H., Guo, L., Zhang, L., Sun, X., Chai, Z. (2019). Experimental and numerical investigation of static and fatigue behaviors of composites honeycomb sandwich structure. Composite Structures, 213, 165–172. doi: https://doi.org/10.1016/j.compstruct.2019.01.081

##submission.downloads##

Опубліковано

Як цитувати

Номер

Розділ

Ліцензія

Авторське право (c) 2023 Muthana Adil Najim Abbu, Doaa Talib Hashim, Hasan Mohammed Ahmed Albegmprli, Mustafa Ridha Mezaal

Ця робота ліцензується відповідно до Creative Commons Attribution 4.0 International License.

Закріплення та умови передачі авторських прав (ідентифікація авторства) здійснюється у Ліцензійному договорі. Зокрема, автори залишають за собою право на авторство свого рукопису та передають журналу право першої публікації цієї роботи на умовах ліцензії Creative Commons CC BY. При цьому вони мають право укладати самостійно додаткові угоди, що стосуються неексклюзивного поширення роботи у тому вигляді, в якому вона була опублікована цим журналом, але за умови збереження посилання на першу публікацію статті в цьому журналі.

Ліцензійний договір – це документ, в якому автор гарантує, що володіє усіма авторськими правами на твір (рукопис, статтю, тощо).

Автори, підписуючи Ліцензійний договір з ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР», мають усі права на подальше використання свого твору за умови посилання на наше видання, в якому твір опублікований. Відповідно до умов Ліцензійного договору, Видавець ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР» не забирає ваші авторські права та отримує від авторів дозвіл на використання та розповсюдження публікації через світові наукові ресурси (власні електронні ресурси, наукометричні бази даних, репозитарії, бібліотеки тощо).

За відсутності підписаного Ліцензійного договору або за відсутністю вказаних в цьому договорі ідентифікаторів, що дають змогу ідентифікувати особу автора, редакція не має права працювати з рукописом.

Важливо пам’ятати, що існує і інший тип угоди між авторами та видавцями – коли авторські права передаються від авторів до видавця. В такому разі автори втрачають права власності на свій твір та не можуть його використовувати в будь-який спосіб.