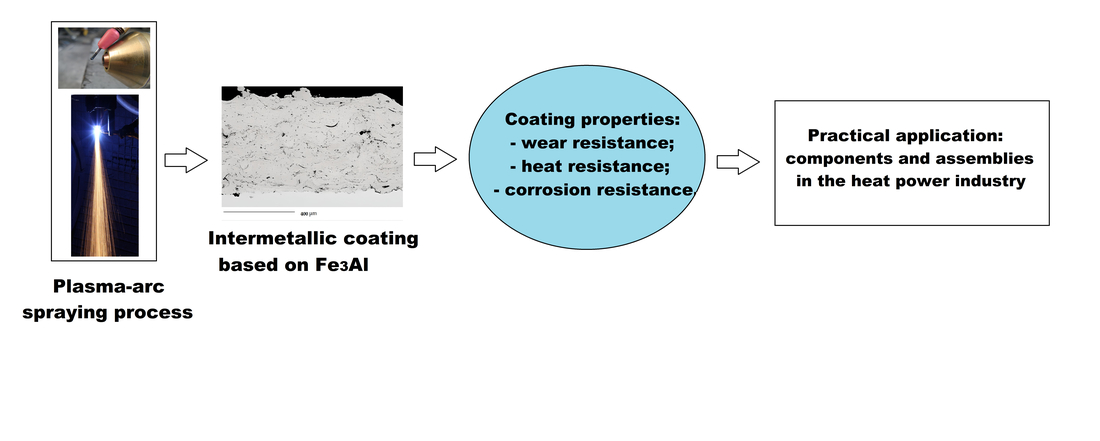

Вплив технологічних параметрів процесу плазмово-дугового напилення порошкового дроту на cтруктуру і властивості інтерметалідних покриттів на основі Fe3Al

DOI:

https://doi.org/10.15587/1729-4061.2023.274062Ключові слова:

плазмово-дугове напилення, порошкові дроти, покриття інтерметалідного типу, корозійна стійкістьАнотація

Існуючі способи нанесення інтерметалідних шарів характеризуються низькою продуктивністю, складнощами пов’язаними з обслуговуванням і експлуатацією технологічного обладнання та значними витратами на закупівлю матеріалів для напилення. Тому, сучасна наука виявляє значний інтерес до питань розробки нових, високоефективних технологій формування на поверхні виробів інтерметалідних покриттів. До таких перспективних способів слід віднести технологію плазмово-дугового напилення (ПДН) порошкових дротів. Цей спосіб має ряд значних переваг, а саме високу продуктивність, відносну просту та доступність обладнання та матеріалів для нанесення покриттів. Було досліджено структуру і властивості покриттів, отриманих ПДН порошкового дроту, в якому сталева оболонка та наповнювач із порошку алюмінію взаємодіє при нагріванні з екзотермічним ефектом синтезу Fe3Al. Шляхом математичного планування експерименту досліджено вплив технологічних параметрів процесу ПДН на структуру та властивості Fe-Al покриттів. З’ясовано, що у всіх зразках основною фазою є інтерметалід типу Fe3Al. Випробування на газоабразивну зносостійкість при кімнатній температурі показали, що зносостійкість покриттів перевищує стійкість сталі S235 в середньому у 2 рази. В результаті досліджень електрохімічних властивостей в 3 % водному розчину NaCl та у 0,5 % розчині H2SO4, визначено бал корозійної стійкості для даних середовищ, cтановить відповідно, 4 і 5 (покриття належать до групи «стійких»). У зв’язку з цим рекомендовано практичне застосування покриттів на основі інтерметаліду Fe3Al для захисту від окиснення, корозії та газоабразивного зносу вузлів і агрегатів в теплоенергетиці (труби теплообмінників, каталітичні нейтралізатори, лопатки парових турбін, запорна арматура, та ін.)

Посилання

- Aliofkhazraei, M. (Ed.) (2018). Intermetallic Compounds - Formation and Applications. IntechOpen. doi: https://doi.org/10.5772/intechopen.68256

- Zamanzade, M., Barnoush, A., Motz, C. (2016). A Review on the Properties of Iron Aluminide Intermetallics. Crystals, 6 (1), 10. doi: https://doi.org/10.3390/cryst6010010

- Borisov, Yu. S., Borisova, A. L., Vigilianska, N. V., Grіshchenko, О. P., Kolomytsev, M. V. (2020). Coatings based on Fe–Al intermetallics produced by the methods of plasma and supersonic air-gas plasma spraying. Automatic Welding, 7, 32–40. doi: https://doi.org/10.37434/as2020.07.04

- Palm, M., Stein, F., Dehm, G. (2019). Iron Aluminides. Annual Review of Materials Research, 49 (1), 297–326. doi: https://doi.org/10.1146/annurev-matsci-070218-125911

- Deevi, S. C. (2021). Advanced intermetallic iron aluminide coatings for high temperature applications. Progress in Materials Science, 118, 100769. doi: https://doi.org/10.1016/j.pmatsci.2020.100769

- Pougoum, F., Qian, J., Martinu, L., Klemberg-Sapieha, J., Zhou, Z., Li, K. Y. et al. (2019). Study of corrosion and tribocorrosion of Fe3Al-based duplex PVD/HVOF coatings against alumina in NaCl solution. Surface and Coatings Technology, 357, 774–783. doi: https://doi.org/10.1016/j.surfcoat.2018.10.060

- Enayati, M. H., Karimzadeh, F., Jafari, M., Markazi, A., Tahvilian, A. (2014). Microstructural and wear characteristics of HVOF-sprayed nanocrystalline NiAl coating. Wear, 309 (1-2), 192–199. doi: https://doi.org/10.1016/j.wear.2013.10.015

- Chmielewski, T., Siwek, P., Chmielewski, M., Piątkowska, A., Grabias, A., Golański, D. (2018). Structure and Selected Properties of Arc Sprayed Coatings Containing In-Situ Fabricated Fe-Al Intermetallic Phases. Metals, 8 (12), 1059. doi: https://doi.org/10.3390/met8121059

- Borisov, Yu. S., Borisova, A. L., Vihilianska, N. V., Demianov, I. A., Burlachenko, O. M. (2021). Electric arc spraying of intermetalic Fe–Al coatings using different solid and powder wires. Automatic Welding, 3, 17–22. doi: https://doi.org/10.37434/as2021.03.03

- Ndumia, J. N., Kang, M., Gbenontin, B. V., Lin, J., Nyambura, S. M. (2021). A Review on the Wear, Corrosion and High-Temperature Resistant Properties of Wire Arc-Sprayed Fe-Based Coatings. Nanomaterials, 11 (10), 2527. doi: https://doi.org/10.3390/nano11102527

- Korzhik, V. N., Korob, M. F. (2012). Mekhanizirovannaya liniya Plazer 30PL-W dlya plazmenno-dugovogo provolochnogo napyleniya pokrytiy na krupnogabaritnye detali tipa «val». Svarschik, 4, 13–15.

- Gulyaev, I. P., Dolmatov, A. V., Kharlamov, M. Yu., Gulyaev, P. Yu., Jordan, V. I., Krivtsun, I. V. et al. (2015). Arc-Plasma Wire Spraying: An Optical Study of Process Phenomenology. Journal of Thermal Spray Technology, 24 (8), 1566–1573. doi: https://doi.org/10.1007/s11666-015-0356-6

- Kharlamov, M. Yu., Krivtsun, I. V., Korzhyk, V. N. (2013). Dynamic Model of the Wire Dispersion Process in Plasma-Arc Spraying. Journal of Thermal Spray Technology, 23 (3), 420–430. doi: https://doi.org/10.1007/s11666-013-0027-4

- Kharlamov, M. Yu., Krivtsun, I. V., Korzhyk, V. N., Ryabovolyk, Y. V., Demyanov, O. I. (2015). Simulation of Motion, Heating, and Breakup of Molten Metal Droplets in the Plasma Jet at Plasma-Arc Spraying. Journal of Thermal Spray Technology, 24 (4), 659–670. doi: https://doi.org/10.1007/s11666-015-0216-4

##submission.downloads##

Опубліковано

Як цитувати

Номер

Розділ

Ліцензія

Авторське право (c) 2023 Volodymyr Korzhyk, Oleksii Burlachenko, Dmytro Strohonov, Nataliia Fialko, Maksym Kharlamov, Oleksandr Grishchenko, Sviatoslav Peleshenko

Ця робота ліцензується відповідно до Creative Commons Attribution 4.0 International License.

Закріплення та умови передачі авторських прав (ідентифікація авторства) здійснюється у Ліцензійному договорі. Зокрема, автори залишають за собою право на авторство свого рукопису та передають журналу право першої публікації цієї роботи на умовах ліцензії Creative Commons CC BY. При цьому вони мають право укладати самостійно додаткові угоди, що стосуються неексклюзивного поширення роботи у тому вигляді, в якому вона була опублікована цим журналом, але за умови збереження посилання на першу публікацію статті в цьому журналі.

Ліцензійний договір – це документ, в якому автор гарантує, що володіє усіма авторськими правами на твір (рукопис, статтю, тощо).

Автори, підписуючи Ліцензійний договір з ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР», мають усі права на подальше використання свого твору за умови посилання на наше видання, в якому твір опублікований. Відповідно до умов Ліцензійного договору, Видавець ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР» не забирає ваші авторські права та отримує від авторів дозвіл на використання та розповсюдження публікації через світові наукові ресурси (власні електронні ресурси, наукометричні бази даних, репозитарії, бібліотеки тощо).

За відсутності підписаного Ліцензійного договору або за відсутністю вказаних в цьому договорі ідентифікаторів, що дають змогу ідентифікувати особу автора, редакція не має права працювати з рукописом.

Важливо пам’ятати, що існує і інший тип угоди між авторами та видавцями – коли авторські права передаються від авторів до видавця. В такому разі автори втрачають права власності на свій твір та не можуть його використовувати в будь-який спосіб.