The effect of alkalization and esterification treatment on mechanical properties of water hyacinth fiber reinforced epoxy-resin composite

DOI:

https://doi.org/10.15587/1729-4061.2023.274064Keywords:

Composite, Natural Fiber, Epoxy-resin, Water Hyacinth, Alkalization, Esterification, Tensile StrengthAbstract

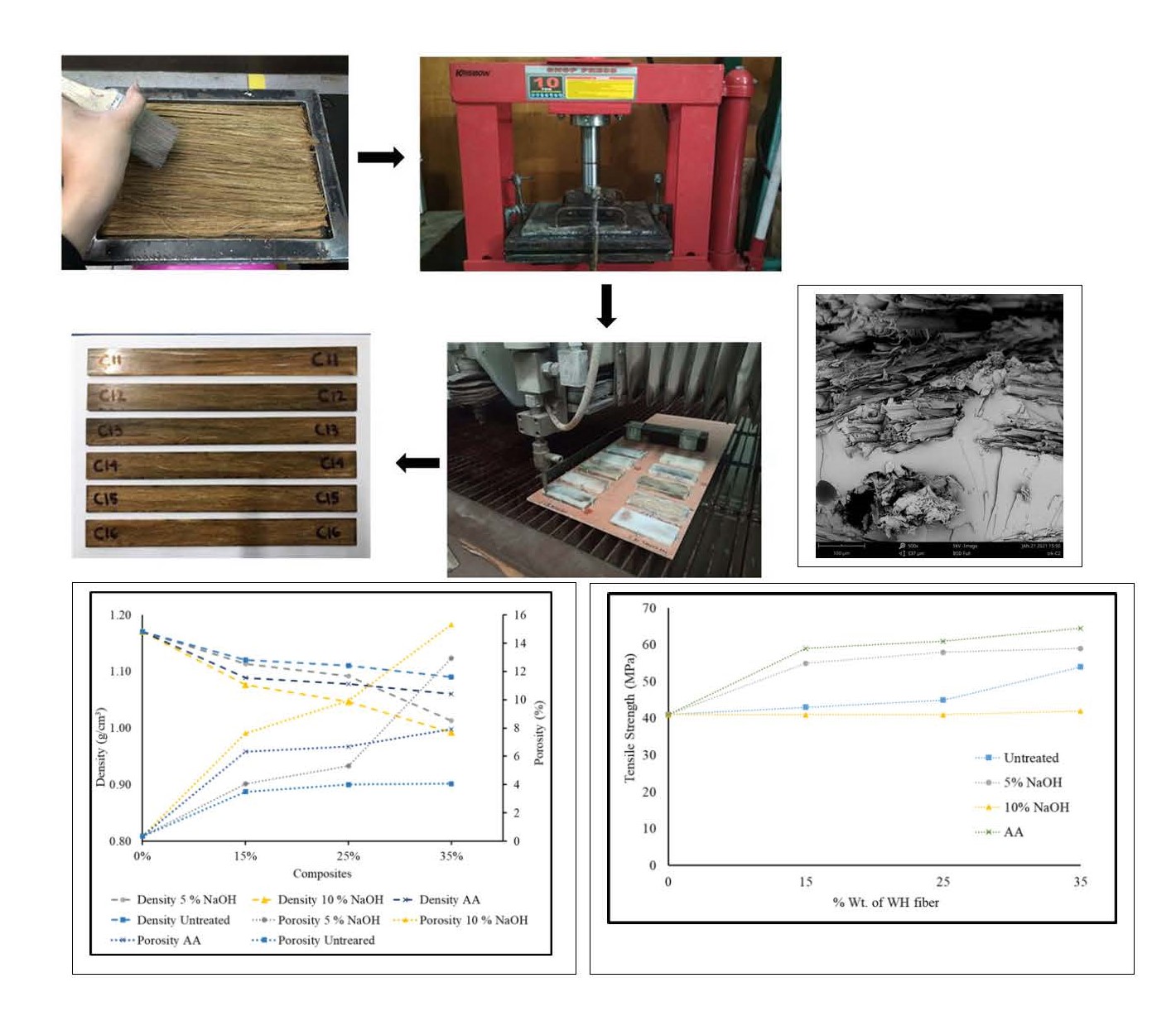

This research investigates the effect of fiber pre-treatment on the mechanical and physical properties of unidirectional water hyacinth (WH) fiber reinforced epoxy resin composites. The water hyacinth fibers have been produced by mechanical processing. The 50–70 cm length of WH stems are brushed with an iron brush to mechanically extract the strands. The dry fibers then were pre-treated by alkalization and esterification. The alkalization ha ve been conducted by immersing the WH fibers on 2 %, 5 % and 10 % NaOH solution for 24 h. The esterification of WH fibers have been done using acetate anhydride. The composite with 15 %, 25 % and 35 % of unidirectional WH fibers was made by hand lay-up. After hand lay up process the WH composites then compacting with pressure compaction 5 MPa. Tensile test and was done based on ASTM D3039. The density of composites was tested based on Archimedes rule. Surface contaminants have been eliminated by fiber treatment. The NaOH treatment eliminated the surface's wax and cuticle. The surface of fibers treated with 10 % NaOH was cleaner than those treated with 5 % NaOH. Fiber treatment has the effect of reducing fiber thickness.The tensile test results of the composite reinforced with WH fiber with NaOH treated and acetate anhydride show that the tensile strength of untreated WH fiber reinforced epoxy resin composites increased with the increase of % WH fiber. The tensile strength results that acetate anhydride treatment of WH fiber reinforced epoxy resin composites showed increased WH fiber increase the tensile strength of composite. The highest tensile strength of epoxy resin reinforced with WH fiber with acetate anhydride treatment

References

- Sindhu, R., Binod, P., Pandey, A., Madhavan, A., Alphonsa, J. A., Vivek, N. et al. (2017). Water hyacinth a potential source for value addition: An overview. Bioresource Technology, 230, 152–162. doi: https://doi.org/10.1016/j.biortech.2017.01.035

- Hidayati, N., Soeprobowati, T. R., Helmi, M. (2018). The evaluation of water hyacinth (Eichhornia crassiper) control program in Rawapening Lake, Central Java Indonesia. IOP Conference Series: Earth and Environmental Science, 142, 012016. doi: https://doi.org/10.1088/1755-1315/142/1/012016

- Teygeler, R. (2000). Water hyacinth paper. Contribution to a sustainable future. Paper and Water, 168–188. Available at: https://www.researchgate.net/profile/Rene-Teijgeler/publication/323226395_Waterhyacintpapier_Bijdrage_aan_een_duurzame_toekomst_Water_hyacinth_paper_Contribution_to_a_sustainable_future_bi-lingual/links/5a870a64aca272017e5aad54/Waterhyacintpapier-Bijdrage-aan-een-duurzame-toekomst-Water-hyacinth-paper-Contribution-to-a-sustainable-future-bi-lingual.pdf

- Choudhary, A. K., Chelladurai, H., Kannan, C. (2015). Optimization of Combustion Performance of Bioethanol (Water Hyacinth) Diesel Blends on Diesel Engine Using Response Surface Methodology. Arabian Journal for Science and Engineering, 40 (12), 3675–3695. doi: https://doi.org/10.1007/s13369-015-1810-y

- Gao, J., Chen, L., Yan, Z., Wang, L. (2013). Effect of ionic liquid pretreatment on the composition, structure and biogas production of water hyacinth (Eichhornia crassipes). Bioresource Technology, 132, 361–364. doi: https://doi.org/10.1016/j.biortech.2012.10.136

- Gupta, A., Balomajumder, C. (2015). Removal of Cr(VI) and phenol using water hyacinth from single and binary solution in the artificial photosynthesis chamber. Journal of Water Process Engineering, 7, 74–82. doi: https://doi.org/10.1016/j.jwpe.2015.05.008

- Rani, S., Sumanjit, Mahajan, R. K. (2015). Comparative study of surface modified carbonizedEichhornia crassipesfor adsorption of dye safranin. Separation Science and Technology, 150629133342008. doi: https://doi.org/10.1080/01496395.2015.1061003

- Romanova, T. E., Shuvaeva, O. V., Belchenko, L. A. (2015). Phytoextraction of trace elements by water hyacinth in contaminated area of gold mine tailing. International Journal of Phytoremediation, 18 (2), 190–194. doi: https://doi.org/10.1080/15226514.2015.1073674

- Pickering, K. L., Efendy, M. G. A., Le, T. M. (2016). A review of recent developments in natural fibre composites and their mechanical performance. Composites Part A: Applied Science and Manufacturing, 83, 98–112. doi: https://doi.org/10.1016/j.compositesa.2015.08.038

- Bordoloi, S., Kashyap, V., Garg, A., Sreedeep, S., Wei, L., Andriyas, S. (2018). Measurement of mechanical characteristics of fiber from a novel invasive weed: A comprehensive comparison with fibers from agricultural crops. Measurement, 113, 62–70. doi: https://doi.org/10.1016/j.measurement.2017.08.044

- Tumolva, T., Ortenero, J., Kubouchi, M. (2013). Characterization and treatment of water hyacinth fibers for NFRP composites. The 19th International Conference on Composite Materials. Montreal.

- Bhuvaneshwari, M., Sangeetha, K. (2017). Development of Water Hyacinth nonwoven fabrics for thermal insulation. Journal on Future Engineering & Technology, 13 (1), 22. doi: https://doi.org/10.26634/jfet.13.1.13759

- Jha, K., Kataria, R., Verma, J., Pradhan, S. (2019). Potential biodegradable matrices and fiber treatment for green composites: A review. AIMS Materials Science, 6 (1), 119–138. doi: https://doi.org/10.3934/matersci.2019.1.119

- Rangappa, S. M., Siengchin, S. (2018). Natural Fibers as Perspective Materials. KMUTNB International Journal of Applied Science and Technology, 11 (4). doi: https://doi.org/10.14416/j.ijast.2018.09.001

- Jawaid, M., Abdul Khalil, H. P. S. (2011). Cellulosic/synthetic fibre reinforced polymer hybrid composites: A review. Carbohydrate Polymers, 86 (1), 1–18. doi: https://doi.org/10.1016/j.carbpol.2011.04.043

- Faruk, O., Bledzki, A. K., Fink, H.-P., Sain, M. (2012). Biocomposites reinforced with natural fibers: 2000–2010. Progress in Polymer Science, 37 (11), 1552–1596. doi: https://doi.org/10.1016/j.progpolymsci.2012.04.003

- Sanjay, M. R., Siengchin, S., Parameswaranpillai, J., Jawaid, M., Pruncu, C. I., Khan, A. (2019). A comprehensive review of techniques for natural fibers as reinforcement in composites: Preparation, processing and characterization. Carbohydrate Polymers, 207, 108–121. doi: https://doi.org/10.1016/j.carbpol.2018.11.083

- Valadez-Gonzalez, A., Cervantes-Uc, J. M., Olayo, R., Herrera-Franco, P. J. (1999). Effect of fiber surface treatment on the fiber–matrix bond strength of natural fiber reinforced composites. Composites Part B: Engineering, 30 (3), 309–320. doi: https://doi.org/10.1016/s1359-8368(98)00054-7

- Chonsakorn, S., Srivorradatpaisan, S., Mongkholrattanasit, R. (2018). Effects of different extraction methods on some properties of water hyacinth fiber. Journal of Natural Fibers, 16 (7), 1015–1025. doi: https://doi.org/10.1080/15440478.2018.1448316

- Kabir, M. M., Wang, H., Lau, K. T., Cardona, F. (2012). Chemical treatments on plant-based natural fibre reinforced polymer composites: An overview. Composites Part B: Engineering, 43 (7), 2883–2892. doi: https://doi.org/10.1016/j.compositesb.2012.04.053

- Sapci, Z. (2013). The effect of microwave pretreatment on biogas production from agricultural straws. Bioresource Technology, 128, 487–494. doi: https://doi.org/10.1016/j.biortech.2012.09.094

- Sood, M., Dwivedi, G. (2018). Effect of fiber treatment on flexural properties of natural fiber reinforced composites: A review. Egyptian Journal of Petroleum, 27 (4), 775–783. doi: https://doi.org/10.1016/j.ejpe.2017.11.005

- Suarsana, I., Suryawan, I., Suardana, N., Winaya, S., Soenoko, R., Suyasa, B. et al. (2021). Flexural strength of hybrid composite resin epoxy reinforced stinging nettle fiber with silane chemical treatment. AIMS Materials Science, 8 (2), 185–199. doi: https://doi.org/10.3934/matersci.2021013

- Supri, A. G., Ismail, H. (2011). The Effect of Isophorone Diisocyanate-Polyhydroxyl Groups Modified Water Hyacinth Fibers (Eichhornia Crassiper) on Properties of Low Density Polyethylene/Acrylonitrile Butadiene Styrene (LDPE/ABS) Composites. Polymer-Plastics Technology and Engineering, 50 (2), 113–120. doi: https://doi.org/10.1080/03602559.2010.531428

- Thiripura Sundari, M., Ramesh, A. (2012). Isolation and characterization of cellulose nanofibers from the aquatic weed water hyacinth – Eichhornia crassipes. Carbohydrate Polymers, 87 (2), 1701–1705. doi: https://doi.org/10.1016/j.carbpol.2011.09.076

- Saputra, A. H., Difandra, A., Pitaloka, A. B. (2013). The Effect of Surface Treatment on Composites of Water Hyacinth Natural Fiber Reinforced Epoxy Resin. Advanced Materials Research, 651, 480–485. doi: https://doi.org/10.4028/www.scientific.net/amr.651.480

- Aleño, J. B., Ramos, H. J., Jose, W. I. (2014). Determination of Properties of yarns made from Water Hyacinth and pinneapple indigenous fibers treated using plasma enhaced chemical vapour deposition. 5th International Conference on Chemical, Ecology and Environmental Sciences (ICCEES'2014). Penang.

- Thi, B. T. N., Thanh, L. H. V., Lan, T. N. P., Thuy, N. T. D., Ju, Y.-H. (2017). Comparison of Some Pretreatment Methods on Cellulose Recovery from Water Hyacinth (Eichhornia Crassipe). Journal of Clean Energy Technologies, 5 (4), 274–279. doi: https://doi.org/10.18178/jocet.2017.5.4.382

- Asrofi, M., Abral, H., Kasim, A., Pratoto, A., Mahardika, M., Hafizulhaq, F. (2018). Mechanical Properties of a Water Hyacinth Nanofiber Cellulose Reinforced Thermoplastic Starch Bionanocomposite: Effect of Ultrasonic Vibration during Processing. Fibers, 6 (2), 40. doi: https://doi.org/10.3390/fib6020040

- Abdel-Fattah, A. F., Abdel-Naby, M. A. (2012). Pretreatment and enzymic saccharification of water hyacinth cellulose. Carbohydrate Polymers, 87 (3), 2109–2113. doi: https://doi.org/10.1016/j.carbpol.2011.10.033

- Sivasankari, B., David Ravindran, A. (2016). A Study on Chemical Analysis of Water Hyacinth (Eichornia crassipes), Water Lettuce (Pistia stratiotes). International Journal of Innovative Research in Science, Engineering and Technology, 5 (10), 17566–17570. doi: https://doi.org/10.15680/ijirset.2016.0510010

- Manimaran, P., Senthamaraikannan, P., Murugananthan, K., Sanjay, M. R. (2017). Physicochemical Properties of New Cellulosic Fibers from Azadirachta indica Plant. Journal of Natural Fibers, 15 (1), 29–38. doi: https://doi.org/10.1080/15440478.2017.1302388

- Ribeiro, A., Pochart, P., Day, A., Mennuni, S., Bono, P., Baret, J.-L. et al. (2015). Microbial diversity observed during hemp retting. Applied Microbiology and Biotechnology, 99 (10), 4471–4484. doi: https://doi.org/10.1007/s00253-014-6356-5

- Khankham, P., Nhuapeng, W., Thamjaree, W. (2017). Fabrication and Mechanical Properties of the Biocomposites between Water Hyacinth Fiber and Paper Mulberry. Key Engineering Materials, 757, 73–77. doi: https://doi.org/10.4028/www.scientific.net/kem.757.73

- Salas-Ruiz, A., Barbero-Barrera, M. del M. (2019). Performance assessment of water hyacinth–cement composite. Construction and Building Materials, 211, 395–407. doi: https://doi.org/10.1016/j.conbuildmat.2019.03.217

- Abral, H., Kadriadi, D., Rodianus, A., Mastariyanto, P., Ilhamdi, Arief, S. et al. (2014). Mechanical properties of water hyacinth fibers – polyester composites before and after immersion in water. Materials & Design, 58, 125–129. doi: https://doi.org/10.1016/j.matdes.2014.01.043

- Huda, N. N., Nath, P., Al Amin, M., Rafiquzzaman, M. (2017). Charpy Impact Behavior of Water Hyacinth Fiber Based Polymer Composite. Journal of Material Science & Manufacturing Technology, 2 (2). Available at: https://www.kuet.ac.bd/webportal/ppmv2/uploads/1509249811Paper-Water%20Hyacinth.pdf

- Supri, A. G., Lim, B. Y. (2009). Effect of Treated and Untreated Filler Loading on the Mechanical, Morphological, and Water Absorption Properties of Water Hyacinth Fibers-Low Density Polyethylene Composites. Journal of Physical Science, 20 (2), 85–96. Available at: http://web.usm.my/jps/20-2-09/JPS%2020_2_%20ART%207%20_85-96_.pdf

- Dantas, L. G., Motta, L. A. de C., Pasquini, D., Vieira, J. G. (2019). Surface Esterification of Sisal Fibres for use as Reinforcement in Cementitious Matrix. Materials Research, 22 (4). doi: https://doi.org/10.1590/1980-5373-mr-2018-0585

- Sulardjaka, S., Iskandar, N., Nugroho, S., Alamsyah, A., Prasetya, M. Y. (2022). The characterization of unidirectional and woven water hyacinth fiber reinforced with epoxy resin composites. Heliyon, 8 (9), e10484. doi: https://doi.org/10.1016/j.heliyon.2022.e10484

- Ajithram, A., Winowlin Jappes, J. T., Siva, I., Brintha, N. C. (2022). Utilizing the aquatic waste and investigation on water hyacinth (Eichhornia crassipes) natural plant in to the fibre composite: Waste recycling. Materials Today: Proceedings, 58, 953–958. doi: https://doi.org/10.1016/j.matpr.2022.02.301

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Sulardjaka Sulardjaka, Norman Iskandar, Parlindungan Manik, Dwi Satrio Nurseto

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.