Determining patterns in loading the body of a gondola with side wall cladding made from corrugated sheets under operating modes

DOI:

https://doi.org/10.15587/1729-4061.2023.275547Keywords:

gondola load, body strength, cladding resistance momentum, body biaxiality indicatorAbstract

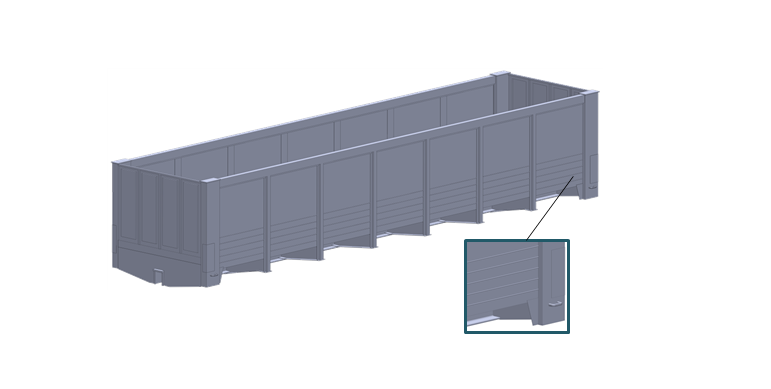

The object of research is the processes of emergence, perception, and redistribution of loads in the body of a universal railroad gondola with a cladding of corrugated sheets.

To improve the strength of the sheets of cladding, it is proposed to strengthen the most loaded area in terms of height (1/3 of the bottom tie-up) with horizontal corrugations. Determination of the geometric parameters of the corrugation is carried out by the moment of resistance of the sheet. The dynamic load of the gondola body with improved cladding was determined by mathematical modeling. The fluctuations of the jump were taken into consideration, that is, the translational movements of the body relative to the vertical axis. The results of the solution of the mathematical model have made it possible to conclude that the studied dynamics indicators are within the permissible limits while the car movement is estimated as "excellent".

The calculation was performed of the strength of the body of a gondola with improved cladding. It has been established that the strength of the gondola body under the main operating load modes is ensured. According to the results of calculations of static strength, the calculation was performed of the fatigue strength of the gondola body. It must be said that the fatigue strength of the body cladding increases by 3.7 % compared to the typical one.

A feature of the results obtained is that the proposed improvement of the cladding can be carried out not only at the design stage but also during repairs of cars.

The scope of practical use of the results includes the engineering industry, in particular railroad transportation. At the same time, the conditions for the practical application of the research results are compliance with the requirements for loading and unloading operations of gondola cars.

The results of the current research will contribute to devising recommendations for the design of modern structures of gondolas and for improving the efficiency of their operation.

References

- Šťastniak, P., Kurčík, P., Pavlík, A. (2018). Design of a new railway wagon for intermodal transport with the adaptable loading platform. MATEC Web of Conferences, 235, 00030. doi: https://doi.org/10.1051/matecconf/201823500030

- Fedosov-Nikonov, D. V., Sulym, A. O., Ilchyshyn, V. V., Safronov, O. M., Kelrikh, M. B. (2020). Study of strength characteristics of the long wheelbase flat cars. IOP Conference Series: Materials Science and Engineering, 985 (1), 012029. doi: https://doi.org/10.1088/1757-899x/985/1/012029

- Viznyak, R. I., Gudko, A. V. (2014). Design improvements filler assembly interim rack bar body in order to ensure gondola cars of strength in service. Zbirnyk naukovykh prats UkrDAZT, 147, 18–22. Available at: http://csw.kart.edu.ua/article/download/74033/69463

- Fedosov-Nikonov, D. V., Strynzha, A. A., Shamshei, D. A., Poluliakh, V. N., Fedorov, V. V., Shushmarchenko, V. A. (2019). The study of corrosion damage to car components during technical diagnostics. Visnyk Skhidnoukrainskoho natsionalnoho universytetu imeni Volodymyra Dalia, 3 (251), 181–185. Available at: http://dspace.luguniv.edu.ua/xmlui/handle/123456789/4845

- Baier, A., Majzner, M. (2012). Application of feature based method in constructing innovative sheathing of railway wagons. Journal of Achievements in Materials and Manufacturing Engineering, 52 (2), 91–98. Available at: https://delibra.bg.polsl.pl/dlibra/publication/35794/edition/32231

- Galimova, F., Khurmatov, Y., Abdulloev, M., Jumabekov, B., Sultonaliev, D., Ergeshova, D. (2021). Modern Gondola with Lightweight Body. Lecture Notes in Networks and Systems, 1043–1050. doi: https://doi.org/10.1007/978-3-030-80946-1_94

- Lee, W. G., Kim, J.-S., Sun, S.-J., Lim, J.-Y. (2016). The next generation material for lightweight railway car body structures: Magnesium alloys. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit, 232 (1), 25–42. doi: https://doi.org/10.1177/0954409716646140

- Olmos Irikovich, Z., Rustam Vyacheslavovich, R., Mahmod Lafta, W., Yadgor Ozodovich, R. (2020). Development of new polymer composite materials for the flooring of rail carriage. International Journal of Engineering & Technology, 9 (2), 378. doi: https://doi.org/10.14419/ijet.v9i2.30519

- Patrascu, A. I., Hadar, A., Pastrama, S. D. (2019). Structural Analysis of a Freight Wagon with Composite Walls. Materiale Plastice, 57 (2), 140–151. doi: https://doi.org/10.37358/mp.20.2.5360

- Buchacz, A., Baier, A., Herbuś, K., Majzner, M., Ociepka, P. (2015). Examination of a Cargo Space of a Freight Wagon Modified with Composite Panels. Applied Mechanics and Materials, 809-810, 944–949. doi: https://doi.org/10.4028/www.scientific.net/amm.809-810.944

- Płaczek, M., Wróbel, A., Olesiejuk, M. (2017). Modelling and arrangement of composite panels in modernized freight cars. MATEC Web of Conferences, 112, 06022. doi: https://doi.org/10.1051/matecconf/201711206022

- Fomin, O., Gorbunov, M., Gerlici, J., Vatulia, G., Lovska, A., Kravchenko, K. (2021). Research into the Strength of an Open Wagon with Double Sidewalls Filled with Aluminium Foam. Materials, 14 (12), 3420. doi: https://doi.org/10.3390/ma14123420

- Domin, Yu. V., Cherniak, H. Yu. (2003). Osnovy dynamiky vahoniv. Kyiv: KUETT, 269.

- Fomin, O., Lovska, A., Skurikhin, D., Nerubatskyi, V., Sushko, D. (2022). Special Features of the Vertical Loading on a Flat Car Transporting Containers with Elastic-Viscous Links in their Interaction Units. 26th International Scientific Conference Transport Means 2022. Kaunas, 629–633.

- Bohach, I. V., Krakovetskyi, O. Yu., Kylyk, L. V. (2020). Chyselni metody rozviazannia dyferentsialnykh rivnian zasobamy MathCad. Vinnytsia, 106. Available at: http://pdf.lib.vntu.edu.ua/books/IRVC/Bogach_2020_106.pdf

- Sobolenko, O. V., Petrechuk, L. M., Ivashchenko, Yu. S., Yehortseva, Ye. Ye. (2020). Metody rishennia matematychnykh zadach u seredovyshchi Mathcad. Dnipro, 60. Available at: https://nmetau.edu.ua/file/navch_posibn_mathcad_2020_petrechuk.pdf

- Pievtsov, H., Turinskyi, O., Zhyvotovskyi, R., Sova, O., Zvieriev, O., Lanetskii, B., Shyshatskyi, A. (2020). Development of an advanced method of finding solutions for neuro-fuzzy expert systems of analysis of the radioelectronic situation. EUREKA: Physics and Engineering, 4, 78–89. doi: https://doi.org/10.21303/2461-4262.2020.001353

- Nerubatskyi, V., Plakhtii, O., Hordiienko, D. (2021). Control and Accounting of Parameters of Electricity Consumption in Distribution Networks. 2021 XXXI International Scientific Symposium Metrology and Metrology Assurance (MMA). doi: https://doi.org/10.1109/mma52675.2021.9610907

- Nerubatskyi, V., Plakhtii, O., Hordiienko, D. (2022). Adaptive Modulation Frequency Selection System in Power Active Filter. 2022 IEEE 8th International Conference on Energy Smart Systems (ESS). doi: https://doi.org/10.1109/ess57819.2022.9969261

- Kondratiev, A. V., Gaidachuk, V. E. (2021). Mathematical Analysis of Technological Parameters for Producing Superfine Prepregs by Flattening Carbon Fibers. Mechanics of Composite Materials, 57 (1), 91–100. doi: https://doi.org/10.1007/s11029-021-09936-3

- Vambol, O., Kondratiev, A., Purhina, S., Shevtsova, M. (2021). Determining the parameters for a 3D-printing process using the fused deposition modeling in order to manufacture an article with the required structural parameters. Eastern-European Journal of Enterprise Technologies, 2 (1 (110)), 70–80. doi: https://doi.org/10.15587/1729-4061.2021.227075

- Harak, S. S., Sharma, S. C., Harsha, S. P. (2014). Structural Dynamic Analysis of Freight Railway Wagon Using Finite Element Method. Procedia Materials Science, 6, 1891–1898. doi: https://doi.org/10.1016/j.mspro.2014.07.221

- Fomin, O., Lovska, A., Khara, M., Nikolaienko, I., Lytvynenko, A., Sova, S. (2022). Adapting the load-bearing structure of a gondola car for transporting high-temperature cargoes. Eastern-European Journal of Enterprise Technologies, 2 (7 (116)), 6–13. doi: https://doi.org/10.15587/1729-4061.2022.253770

- Fomin, O., Lovska, A. (2021). Determination of dynamic loading of bearing structures of freight wagons with actual dimensions. Eastern-European Journal of Enterprise Technologies, 2 (7 (110)), 6–14. doi: https://doi.org/10.15587/1729-4061.2021.220534

- Lovska, A., Fomin, O., Píštěk, V., Kučera, P. (2020). Dynamic Load and Strength Determination of Carrying Structure of Wagons Transported by Ferries. Journal of Marine Science and Engineering, 8 (11), 902. doi: https://doi.org/10.3390/jmse8110902

- Lovska, A. (2014). Assessment of dynamic efforts to bodies of wagons at transportation with railway ferries. Eastern-European Journal of Enterprise Technologies, 3 (4 (69)), 36–41. doi: https://doi.org/10.15587/1729-4061.2014.24997

- Panchenko, S., Vatulia, G., Lovska, A., Ravlyuk, V., Elyazov, I., Huseynov, I. (2022). Influence of structural solutions of an improved brake cylinder of a freight car of railway transport on its load in operation. EUREKA: Physics and Engineering, 6, 45–55. doi: https://doi.org/10.21303/2461-4262.2022.002638

- Panchenko, S., Gerlici, J., Vatulia, G., Lovska, A., Pavliuchenkov, M., Kravchenko, K. (2022). The Analysis of the Loading and the Strength of the FLAT RACK Removable Module with Viscoelastic Bonds in the Fittings. Applied Sciences, 13 (1), 79. doi: https://doi.org/10.3390/app13010079

- Dižo, J., Harušinec, J., Blatnický, M. (2017). Structural Analysis of a Modified Freight Wagon Bogie Frame. MATEC Web of Conferences, 134, 00010. doi: https://doi.org/10.1051/matecconf/201713400010

- Dižo, J., Blatnický, M., Steišūnas, S., Skočilasová, B. (2018). Assessment of a rail vehicle running with the damaged wheel on a ride comfort for passengers. MATEC Web of Conferences, 157, 03004. doi: https://doi.org/10.1051/matecconf/201815703004

- Koziar, M. M., Feshchuk, Yu. V., Parfeniuk, O. V. (2018). Kompiuterna hrafika: SolidWorks. Kherson: Oldi-plius, 252. Available at: https://ep3.nuwm.edu.ua/22175/1/%D0%9A%D0%BE%D0%BC%D0%BF%27%D1%8E%D1%82%D0%B5%D1%80%D0%BD%D0%B0%20%D0%B3%D1%80%D0%B0%D1%84%D1%96%D0%BA%D0%B0.pdf

- Pustiulha, S. I., Samostian, V. R., Klak, Yu. V. (2018). Inzhenerna hrafika v SolidWorks. Lutsk: Vezha, 172. Available at: https://lib.lntu.edu.ua/sites/default/files/2021-02/%D0%86%D0%BD%D0%B6%D0%B5%D0%BD%D0%B5%D1%80%D0%BD%D0%B0%20%D0%B3%D1%80%D0%B0%D1%84%D1%96%D0%BA%D0%B0%20%D0%B2%20SolidWorks.pdf

- Chykhladze, E. D. (2011). Opir materialiv. Kharkiv: UkrDAZT, 360. Available at: http://lib.kart.edu.ua/handle/123456789/4985

- Shvabiuk, V. I. (2016). Opir materialiv. Kyiv: Znannia, 400. Available at: https://btpm.nmu.org.ua/ua/download/navch-posib/%D0%A8%D0%B2%D0%B0%D0%B1%D1%8E%D0%BA.%D0%9E%D0%9C.%D0%9F%D1%96%D0%B4%D1%80%D1%83%D1%87%D0%BD%D0%B8%D0%BA.pdf

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Glib Vatulia, Alyona Lovska, Sergiy Myamlin, Andrij Rybin, Volodymyr Nerubatskyi, Denys Hordiienko

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.