Development of ways to saving energy when operating winding machines

DOI:

https://doi.org/10.15587/1729-4061.2023.275915Keywords:

textile industry, energy saving, winding machine, productivity machine, bobbin changer apparatusAbstract

Energy efficiency or energy saving is the practical implementation of scientific, technical, economic and industrial measures aimed at the efficient use of energy resources. Therefore, one of the challenges facing the textile industry is energy saving in technological processes in the production of products. To solve this problem, it is proposed to introduce into production advanced technological processes with low energy costs, the use of technological equipment equipped with electric motors with high rates of consumed electrical energy. This problem is also inherent in winders and similar machines equipped with a bobbin changer.

Since most of the time of operation of these devices is wasted and, accordingly, electricity is also wasted. However, to date, these issues have not been given due attention, and studies on this subject have not been conducted. In this work, the operation of the apparatus for changing bobbins in winding and similar machines has been studied in order to reduce power consumption.

As a result of the study, a mathematical model of the relationship between the operating mode and technological parameters of machines and apparatuses was obtained, which makes it possible to identify ways to eliminate shortcomings in their work.

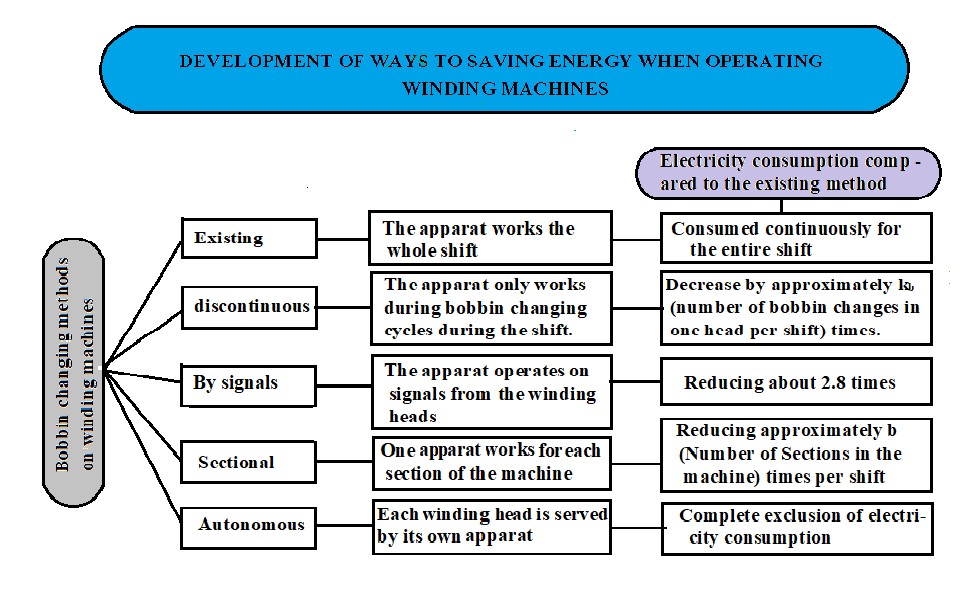

Discontinuous, on signal and sectional methods of operation of the apparatus for changing bobbins have been developed, which make it possible to reduce power consumption on winding machines by 2.8–4.2 times compared to the existing method of operation. And the autonomous method of operation of the device, proposed in the work, completely eliminates the consumption of electricity consumed by the device for changing bobbins. The results of the study can be used in spinning and weaving mills.

References

- Sposoby ekonomii elektroenergii na proizvodstve. Available at: https://club.cnews.ru/blogs/entry/sposoby_ekonomii_elektroenergii_na_proizvodstve?ysclid=la2ae77zcc113360571,%20доступ%204.11.2022

- Dhayaneswaran, Y., Ashokkumar, L. (2013). A Study on Energy Conservation in Textile Industry. Journal of The Institution of Engineers (India): Series B, 94 (1), 53–60. doi: https://doi.org/10.1007/s40031-013-0040-5

- Khude, P. (2017). A Review on Energy Management in Textile Industry. Innovative Energy & Research, 06 (02). doi:https://doi.org/10.4172/2576-1463.1000169

- Kobeyeva, Z., Khussanov, A., Atamanyuk, V., Hnativ, Z., Kaldybayeva, B., Janabayev, D., Gnylianska, L. (2022). Analyzing the kinetics in the filtration drying of crushed cotton stalks. Eastern-European Journal of Enterprise Technologies, 1 (8 (115)), 55–66. doi:https://doi.org/10.15587/1729-4061.2022.252352

- Bezbah, I., Zykov, A., Mordynskyi, V., Osadchuk, P., Phylipova, L., Bandura, V. et al. (2022). Designing the structure and determining the mode characteristics of the grain dryer based on thermosiphons. Eastern-European Journal of Enterprise Technologies, 2 (8 (116)), 54–61. doi:https://doi.org/10.15587/1729-4061.2022.253977

- Hasanbeigi, A., Price, L. (2012). A review of energy use and energy efficiency technologies for the textile industry. Renewable and Sustainable Energy Reviews, 16 (6), 3648–3665. doi:https://doi.org/10.1016/j.rser.2012.03.029

- Fjodorov, A. S., Karavajkov, V. M. The basıc dırectıons of economy of energy ın the textıle ındustry. Available at: http://science-bsea.bgita.ru/2013/ekonom_2013_19/fedorov_osnov.htm

- Karavaykov, V. M. (2004) Organizatsiya upravleniya energoeffektivnost'yu tekstil'nogo proizvodstva. Kostroma.

- Koç, E., Kaplan, E. (2007). Tekstil Terbiye İşletmelerinde Enerji Kullanımı-Genel Değerlendirme. Tekstil ve Mühendis, 13 (65), 39–47. Available at: https://www.tekstilvemuhendis.org.tr/showpublish.php?pubid=92&type=full

- Demessınova, A. A., Aıdarova, A. B., Maulenkulova, G. E., Mamutova, K. K. (2020). Energy securıty of the textıle ındustry. Tekhnologiya tekstil'noy promyshlennosti, 4, 142–147. Available at: https://ttp.ivgpu.com/wp-content/uploads/2021/01/388_24.pdf

- Kutumova, E. O., Kutumova, E. V., Matvievskaya, N. Yu. (2012). Innovatsionnaya ekonomika tekstil'nykh predpriyatiy kak instrument snizheniya energoemkosti valovogo regional'nogo produkta. Sovremennye naukoemkie tekhnologii. Regional'noe prilozhenie, 3 (31), 33–39.

- Fettahov, R. (2006). Pat. No. 200601193 TR. İplik Boyama ve Terbiye Amaçlı Patron.

- Fettahov, R., Palamutçu, S. (2010). Pat. No. 200707013 TR. İplik Boyama ve Terbiye İçin Plastik Patron.

- Makhmudova, N. R. (2020). Vliyanie konstruktsii patrona na krashenie pryazhi na bobinakh. Tekhnologiya tekstil'noy promyshlennosti, 5 (389), 69–73.

- Şimşek Gündüz, G. (2015). İpliklerin Farklı Patron Tipleri İle Bobin Halinde Boyanmasında Ağartma İşleminin Etkilerinin İncelenmesi. Yüksek Lisans Tezi, 410782, 149.

- Altıntaş, M. (2010). Patron Yapısının Bobin Boyamaya Etkisinin Araştırılması. Yüksek lisans tezi, 70–71.

- Tok elektrodvigatelya, kakuyu silu toka potreblyaet dvigatel' pri puske i rabote. kak uznat' puskovoy i nominal'nyy tok elektromotora, dvizhka. Available at: https://oooevna.ru/kakoj-tok-potreblaet-dvigatel-iz-seti-pri-puske-i-rabote

- Ivanova, T. P. (2008). Tekhnologiya i oborudovanie dlya podgotovki nitey k tkachestvu. Vitebsk, 315.

- Bobinleme Makinesi Kataloğu, Revised Dec (2008). Murata Machinery Ltd.

- Schlafhorst Autoconer 338 DW (2006). Bobinleme Makinesi Kataloğu.

- Solnyshkina, I. V. (2015). Teoriya massovogo obsluzhivaniya. Komsomol'sko na Amure.

- Bronshteyn, I. N., Semendyaev, K. A. (1986). Spravochnik po matematike dlya inzhenerov i uchaschikhsya vuzov. Moscow, 138.

- Fettahov, R., İkiz, Y. (2002). Pamuklu Dokuma Hazırlık Manikalarında Randıman ve Üretim Normu Tespiti. Tekstil Maraton, 50–55.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Nigar Makhmudova

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.