The development of composite reinforced hybrid fiber musa acuminata stem-hibiscus tiliaceust bark with filler liquid rubber as vehicle bumper

DOI:

https://doi.org/10.15587/1729-4061.2023.276642Keywords:

musa acuminata, stem, hibiscus tiliaceust, bark, fiber, polyester composite, tensile strength, impact thoughnes, heat shrinkage, vehicle bumperAbstract

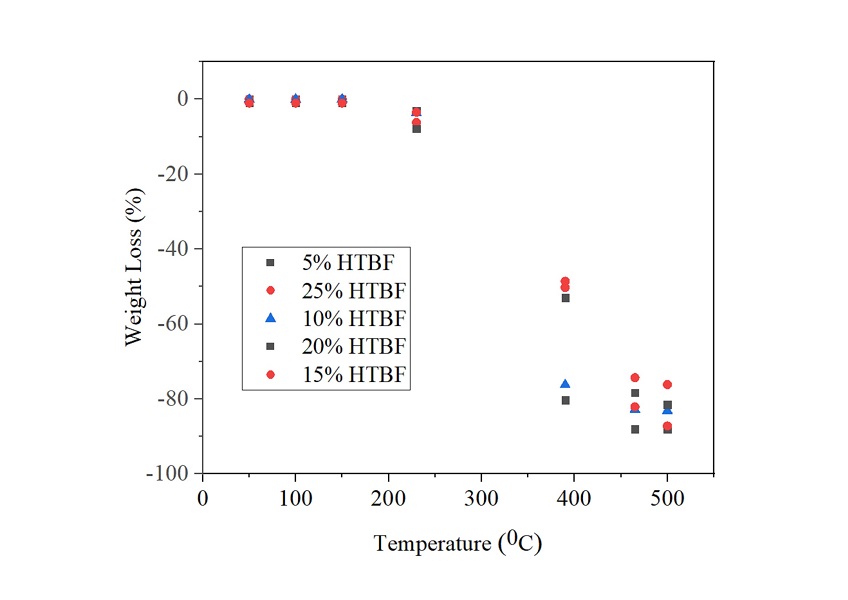

The characterized of the polyester composites reinforced of the hybrid fiber musa acuminata stem fiber (MASF)-hibiscus tiliaceust bark fiber (HTBF) with liquid rubber filler was studied. The object of research is the polyester composite material, hybrid natural fiber reinforcement and filler Carboxyl Terminated Butadiene Acrylonitryle (CTBN). The polyester composite material which is used as a vehicle bumper, is easily broken and has low heat resistance so that its shape easily changes/shrinks due to heat. This research aims to develop the tensile strength, impact toughness and heat resistance of polyester composites. The reason for using the MASF-HTBF hybrid fiber as a reinforcement for polyester composite materials is because MASF and HTBF are natural fibers that have great potential to be developed to improve the mechanical properties of polyester composites, as substitutes for synthetic fibers. In this study, the conditions of MASF and HTBF were given alkaline treatment by immersing them in 5 % NaOH solution for 24 hours then drying. The combined/hybrid ratio between the MASF and CTBF volume fractions is: 5 %:25 %, 10 %:20 % and 15 %:15 %. To increase impact toughness, CTBN filler is added with variations of 5 %, 10 %. The mechanical characteristics of the specimens were carried out by means of a tensile test and an impact test. The change in mass or shrinkage as a result is tested by TGA. The results showed that the MASF-HTBF hybrid fiber-reinforced polyester composite material with CTBN filler has better mechanical properties than single natural fibers, so it is important to develop it further as a material for making vehicle bumper

Supporting Agency

- The authors thank Prof. Rudy Soenoko, Prof. Wahyono Suprapto are acknowledged for invaluable endless collaborations. Prof. I.G.N Wardhana Director Postgraduated Doctor Mechanical Engineering Program Brawijaya University permission to use of laboratory and other resource materials

References

- Braga, R., Magalhaes, Jr, P. (2014). Rear Bumper Laminated In Jute Fiber With Polyester Resin. International Journal of Engineering Research and Applications, 4 (9), 174–184.

- Mir, A., Zitoune, R., Collombet, F., Bezzazi, B. (2009). Study of Mechanical and Thermomechanical Properties of Jute/Epoxy Composite Laminate. Journal of Reinforced Plastics and Composites, 29 (11), 1669–1680. doi: https://doi.org/10.1177/0731684409341672

- Sanjay, M. R., Arpitha, G. R., Yogesha, B. (2015). Study on Mechanical Properties of Natural - Glass Fibre Reinforced Polymer Hybrid Composites: A Review. Materials Today: Proceedings, 2 (4-5), 2959–2967. doi: https://doi.org/10.1016/j.matpr.2015.07.264

- Davoodi, M. M., Sapuan, S. M., Ali, A., Ahmad, D., Khalina, A. (2010). Thermoplastic impact property improvement in hybrid natural fibre epoxy composite bumper beam. IOP Conference Series: Materials Science and Engineering, 11, 012013. doi: https://doi.org/10.1088/1757-899x/11/1/012013

- Hassan, C. S., Pei, Q., Sapuan, S. M., Abdul Aziz, N., Mohamed Yusoff, M. Z. (2018). Crash Performance of Oil Palm Empty Fruit Bunch (OPEFB) Fibre Reinforced Epoxy Composite Bumper Beam using Finite Element Analysis. International Journal of Automotive and Mechanical Engineering, 15 (4), 5826–5836. doi: https://doi.org/10.15282/ijame.15.4.2018.9.0446

- Ragupathi, P., Sivaram, N. M., Vignesh, G., Milon D., S. (2018). Enhancement of impact strength of a car bumper using natural fiber composite made of jute. I-Manager’s Journal on Mechanical Engineering, 8 (3), 39. doi: https://doi.org/10.26634/jme.8.3.14737

- Davoodi, M. M., Sapuan, S. M., Ahmad, D., Aidy, A., Khalina, A., Jonoobi, M. (2011). Concept selection of car bumper beam with developed hybrid bio-composite material. Materials & Design, 32 (10), 4857–4865. doi: https://doi.org/10.1016/j.matdes.2011.06.011

- Irawan, A. P., Anggarina, P. T., Utama, D. W., Najid, N., Abdullah, M. Z., Siregar, J. P. et al. (2022). An Experimental Investigation into Mechanical and Thermal Properties of Hybrid Woven Rattan/Glass-Fiber-Reinforced Epoxy Composites. Polymers, 14 (24), 5562. doi: https://doi.org/10.3390/polym14245562

- Cao, Y., Wang, W., Wang, Q., Wang, H. (2013). Application of Mechanical Models to Flax Fiber /Wood Fiber/ Plastic Composites. BioResources, 8 (3). doi: https://doi.org/10.15376/biores.8.3.3276-3288

- Daud, M. A. M., Ab. Ghani, A. F., Zakaria, K. A., Selamat, M. Z., Dharmalingam, S., Thirukumaran, M. (2021). The Effect of Pineapple Leaf Fiber as a Filler in Polymer Matrix Composite for Interior Part in Automotive. International Journal of Nanoelectronics and Materials, 14, 363–372. Available at: https://www.researchgate.net/publication/354311026_The_Effect_of_Pineapple_Leaf_Fiber_as_a_Filler_in_Polymer_Matrix_Composite_for_Interior_Part_in_Automotive

- Sujita, S., Sutanto, R. (2022). Characteristics of polyester composite reinforced hybrid Hibiscus tiliaceust bark and palm fibers as harrow comb (leveler) material. World Journal of Advanced Engineering Technology and Sciences, 7 (1), 113–119. doi: https://doi.org/10.30574/wjaets.2022.7.1.0100

- Sujita, S., Sari, N. H. (2022). The greatness of the characteristics fiber pseudo stem outer layer of Musa acuminata origin lombok Indonesia as reinforcing polyester composite. Eastern-European Journal of Enterprise Technologies, 4 (12 (118)), 38–43. doi: https://doi.org/10.15587/1729-4061.2022.261921

- Gabr, M. H., Elrahman, M. A., Okubo, K., Fujii, T. (2010). A study on mechanical properties of bacterial cellulose/epoxy reinforced by plain woven carbon fiber modified with liquid rubber. Composites Part A: Applied Science and Manufacturing, 41 (9), 1263–1271. doi: https://doi.org/10.1016/j.compositesa.2010.05.010

- Kim, J., Kim, J. (2017). Epoxy Resins Toughened with Surface Modified Epoxidized Natural Rubber Fibers by One-Step Electrospinning. Materials, 10 (5), 464. doi: https://doi.org/10.3390/ma10050464

- Dudin, V., Makarenko, D., Derkach, O., Muranov, Y. (2022). Determining the influence of a filler on the properties of composite materials based on Phenylone C2 for tribojunctions in machines and assemblies. Eastern-European Journal of Enterprise Technologies, 5 (12 (119)), 38–46. doi: https://doi.org/10.15587/1729-4061.2022.266160

- Manik, P., Suprihanto, A., Nugroho, S., Sulardjaka, S. (2021). The effect of lamina configuration and compaction pressure on mechanical properties of laminated gigantochloa apus composites. Eastern-European Journal of Enterprise Technologies, 6 (12 (114)), 62–73. doi: https://doi.org/10.15587/1729-4061.2021.243993

- Mujiyono, M., Nurhadiyanto, D., Mukhammad, A. F. H., Riyadi, T. W. B., Wahyudi, K., Kholis, N. et al. (2023). Damage formations of ramie fiber composites multilayer armour system under high-velocity impacts. Eastern-European Journal of Enterprise Technologies, 1 (12 (121)), 16–25. doi: https://doi.org/10.15587/1729-4061.2023.273788

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Sujita Darmo, Rudy Sutanto

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.