Визначення втомної поведінки композитної однострунної конструкції на основі квазістатичного методу

DOI:

https://doi.org/10.15587/1729-4061.2023.277911Ключові слова:

спрямована деформація, аналіз зсуву, загальна деформація, еквівалентні напруження, композиційна структураАнотація

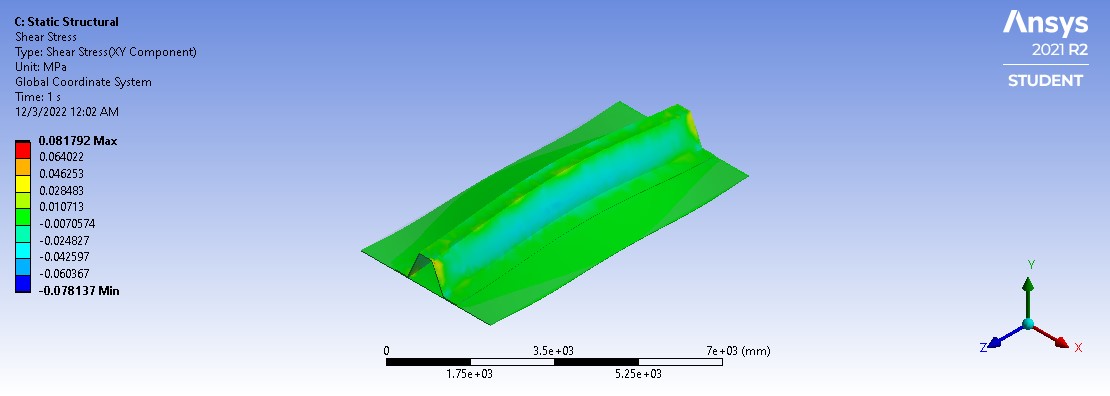

У цьому дослідженні механічна поведінка композитної однострунної конструкції була піддана числовому аналізу, щоб краще зрозуміти її властивості. Як основний матеріал для процесу моделювання використовувався вуглецевий епоксид IM7/8552 з квазіізотропними Layups. Результати числового аналізу, проведеного на конструкції, коли вона перебувала в статичному стані, були введені в структурний інструмент, розроблений програмою ANSYS. Фундаментальні граничні умови були визначені на основі інформації, отриманої від випробувань. Статичні сили із сумарною величиною 13,7 кН застосовуються до композитної однострунної конструкції. Доведено, що напруження зсуву, напрямна деформація, напруги фон Мізеса та повна деформація впливають на механічну поведінку матеріалу, і цей ефект було продемонстровано. Розрахунки показують, що існує максимальна величина вигину, яка може мати місце як прямий результат прикладеного навантаження, і ця величина дорівнює 0,0147. Внаслідок застосування тиску 13,7 кН напруга фон-Мізеса, яку також часто називають порівнянними напругами, досягла 51,9 МПа. Напруги зсуву були оцінені за трьома різними планами, і було виявлено, що напруга зсуву, прикладена до площини XY, досягла максимуму 15 МПа, але напруга зсуву, прикладена до площини XZ, досягла максимуму 9,8 МПа. У цей час напруга зсуву на площині YZ досягла рівня 1,5 МПа.

Посилання

- Raimondo, A., Doesburg, S. A., Bisagni, C. (2020). Numerical study of quasi-static and fatigue delamination growth in a post-buckled composite stiffened panel. Composites Part B: Engineering, 182, 107589. doi: https://doi.org/10.1016/j.compositesb.2019.107589

- Zalameda, J., Winfree, W. (2018). Detection and Characterization of Damage in Quasi-Static Loaded Composite Structures using Passive Thermography. Sensors, 18 (10), 3562. doi: https://doi.org/10.3390/s18103562

- Zalameda, J. N., Winfree, W. P., Horne, M. R. (2018). Detection of Damage During Quasi-Static Loading of a Single Stringer Panel Using Passive Thermography and Acoustic Emission. Conference Proceedings of the Society for Experimental Mechanics Series, 77–86. doi: https://doi.org/10.1007/978-3-319-95074-7_15

- Raimondo, A., Mendez, J. P., Bisagni, C. (2021). Experimental study on post-buckled composite single-stringer specimens with initial delamination under fatigue loads. American Society for Composites 2021. doi: https://doi.org/10.12783/asc36/35772

- Winfree, W. P., Zalameda, J. N., Horne, M. R. (2019). Simulations of thermal signatures of damage measured during quasi-static loading of a single stringer panel. AIP Conference Proceedings. doi: https://doi.org/10.1063/1.5099849

- Milanoski, D., Galanopoulos, G., Broer, A., Zarouchas, D., Loutas, T. (2021). A Strain-Based Health Indicator for the SHM of Skin-to-Stringer Disbond Growth of Composite Stiffened Panels in Fatigue. European Workshop on Structural Health Monitoring, 626–635. doi: https://doi.org/10.1007/978-3-030-64594-6_61

- Horne, M. R., Zalameda, J. N. (2018). Real time detection of damage during quasi-static loading of a single stringer panel using passive thermography. Thermosense: Thermal Infrared Applications XL. doi: https://doi.org/10.1117/12.2305613

- Zalameda, J. N., Winfree, W. P., Horne, M. R. (2019). Characterization of damage formation in a composite single stringer hat stiffened panel using passive thermography. AIP Conference Proceedings. doi: https://doi.org/10.1063/1.5099753

- Seneviratne, W., Saseendran, V., Shafie, M., Tomblin, J. (2021). Skin/stringer interface damage characterization of stiffened composite structures. American Society for Composites 2021. doi: https://doi.org/10.12783/asc36/35929

- Milanoski, D., Galanopoulos, G., Zarouchas, D., Loutas, T. (2022). Damage Diagnostics on Post-buckled Stiffened Panels Utilizing the Digital-Twin Concept. European Workshop on Structural Health Monitoring, 213–222. doi: https://doi.org/10.1007/978-3-031-07254-3_21

- van Dooren, K. S., Tijs, B. H. A. H., Waleson, J. E. A., Bisagni, C. (2023). Skin-stringer separation in post-buckling of butt-joint stiffened thermoplastic composite panels. Composite Structures, 304, 116294. doi: https://doi.org/10.1016/j.compstruct.2022.116294

- Xiong, J., Zhu, Y., Luo, C., Li, Y. (2021). Fatigue-driven failure criterion for progressive damage modelling and fatigue life prediction of composite structures. International Journal of Fatigue, 145, 106110. doi: https://doi.org/10.1016/j.ijfatigue.2020.106110

- Dogan, A. (2022). Quasi-static and dynamic response of functionally graded viscoelastic plates. Composite Structures, 280, 114883. doi: https://doi.org/10.1016/j.compstruct.2021.114883

- Chen, J., Fang, H., Liu, W., Zhu, L., Zhuang, Y., Wang, J., Han, J. (2018). Energy absorption of foam-filled multi-cell composite panels under quasi-static compression. Composites Part B: Engineering, 153, 295–305. doi: https://doi.org/10.1016/j.compositesb.2018.08.122

- Zha, Y., Ma, Q., Gan, X., Cai, M., Zhou, T. (2020). Deformation and energy absorption characters of Al‐CFRP hybrid tubes under quasi‐static radial compression. Polymer Composites, 41 (11), 4602–4618. doi: https://doi.org/10.1002/pc.25737

- Shruti, M., Sri Hemanth, N., Badgayan, N. D., Sahu, S. K. (2021). Compressive behavior of auxetic structural metamaterial for lightweight construction using ANSYS static structural analysis. Materials Today: Proceedings, 38, 12–17. doi: https://doi.org/10.1016/j.matpr.2020.05.410

- Mirrudula, P., Priya, P. K., Malavika, M., Kumar, G. R., Vijayanandh, R., Kumar, M. S. (2020). Comparative structural analysis of the sandwich composite using advanced numerical simulation. AIP Conference Proceedings. doi: https://doi.org/10.1063/5.0019370

- Saravanakumar, S., Kumar Chandramohan, N., Tamil Prabakaran, S., Muniyappan, M., Shanmugam, M., Shaisundaram, V. S. (2021). The static structural analysis of torque converter material for better performance by changing the stator angle. Materials Today: Proceedings, 37, 1963–1972. doi: https://doi.org/10.1016/j.matpr.2020.07.487

- Vijayanandh, R., Venkatesan, K., Ramesh, M., Raj Kumar, G., Senthil Kumar, M. (2019). Optimization of orientation of carbon fiber reinforced polymer based on structural analysis. International Journal of Scientific & Technology Research, 8 (11), 3020–3029. Available at: http://www.ijstr.org/final-print/nov2019/Optimization-Of-Orientation-Of-Carbon-Fiber-Reinforced-Polymer-Based-On-Structural-Analysis-.pdf

- Htet, T. L. (2020). Structural analysis and topology design optimization of load bearing elements of aircraft fuselage structure. IOP Conference Series: Materials Science and Engineering, 709 (4), 044113. doi: https://doi.org/10.1088/1757-899x/709/4/044113

- Carneiro, P. M. C., Gamboa, P. (2019). Structural analysis of wing ribs obtained by additive manufacturing. Rapid Prototyping Journal, 25 (4), 708–720. doi: https://doi.org/10.1108/rpj-02-2018-0044

- Pennington, A., Goyal, V. (2023). Integration of Fatigue R-Curve Effects into VCCT for Durability Predictions, Part 1: Buckled Composite Single-Stringer Stiffened Panels. AIAA SCITECH 2023 Forum. doi: https://doi.org/10.2514/6.2023-0952

- Martulli, L. M., Bernasconi, A. (2023). An efficient and versatile use of the VCCT for composites delamination growth under fatigue loadings in 3D numerical analysis: the Sequential Static Fatigue algorithm. International Journal of Fatigue, 170, 107493. doi: https://doi.org/10.1016/j.ijfatigue.2022.107493

- Chiang, C.-H., Hidayat, M., Kumar, D. (2022). Simulated thermal image based on finite element models for a layered composite structures. Materials Today: Proceedings, 57, 871–877. doi: https://doi.org/10.1016/j.matpr.2022.02.539

- Tan, R., Xu, J., Guan, Z., Sun, W., Ouyang, T., Wang, S. (2020). Experimental study on effect of impact locations on damage formation and compression behavior of stiffened composite panels with L-shaped stiffener. Thin-Walled Structures, 150, 106707. doi: https://doi.org/10.1016/j.tws.2020.106707

- Saeedifar, M., Saleh, M. N., Nijhuis, P., de Freitas, S. T., Zarouchas, D. (2021). Damage assessment of a titanium skin adhesively bonded to carbon fiber–reinforced plastic omega stringers using acoustic emission. Structural Health Monitoring, 21 (2), 407–423. doi: https://doi.org/10.1177/14759217211001752

- Ciminello, M., Boffa, N. D., Concilio, A., Galasso, B., Romano, F., Monaco, E. (2020). Damage Detection of CFRP Stiffened Panels by Using Cross-Correlated Spatially Shifted Distributed Strain Sensors. Applied Sciences, 10 (8), 2662. doi: https://doi.org/10.3390/app10082662

##submission.downloads##

Опубліковано

Як цитувати

Номер

Розділ

Ліцензія

Авторське право (c) 2023 Ali Talib Shomran, Batool Mardan Faisal, Emad Kamil Hussein, Thiago Santos, Kies Fatima

Ця робота ліцензується відповідно до Creative Commons Attribution 4.0 International License.

Закріплення та умови передачі авторських прав (ідентифікація авторства) здійснюється у Ліцензійному договорі. Зокрема, автори залишають за собою право на авторство свого рукопису та передають журналу право першої публікації цієї роботи на умовах ліцензії Creative Commons CC BY. При цьому вони мають право укладати самостійно додаткові угоди, що стосуються неексклюзивного поширення роботи у тому вигляді, в якому вона була опублікована цим журналом, але за умови збереження посилання на першу публікацію статті в цьому журналі.

Ліцензійний договір – це документ, в якому автор гарантує, що володіє усіма авторськими правами на твір (рукопис, статтю, тощо).

Автори, підписуючи Ліцензійний договір з ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР», мають усі права на подальше використання свого твору за умови посилання на наше видання, в якому твір опублікований. Відповідно до умов Ліцензійного договору, Видавець ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР» не забирає ваші авторські права та отримує від авторів дозвіл на використання та розповсюдження публікації через світові наукові ресурси (власні електронні ресурси, наукометричні бази даних, репозитарії, бібліотеки тощо).

За відсутності підписаного Ліцензійного договору або за відсутністю вказаних в цьому договорі ідентифікаторів, що дають змогу ідентифікувати особу автора, редакція не має права працювати з рукописом.

Важливо пам’ятати, що існує і інший тип угоди між авторами та видавцями – коли авторські права передаються від авторів до видавця. В такому разі автори втрачають права власності на свій твір та не можуть його використовувати в будь-який спосіб.