Вплив уплотнення на корозійну стійкість анодування борною сірчаною кислотою на AA2024

DOI:

https://doi.org/10.15587/1729-4061.2023.277961Ключові слова:

корозійна стійкість, оцтова кислота, AA2024, анодування борною кислотоюАнотація

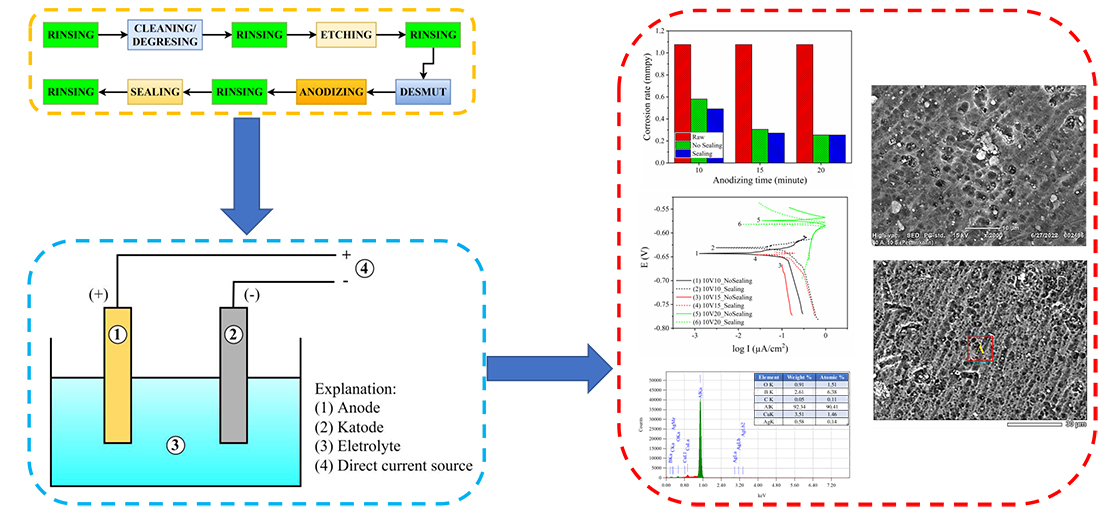

Алюміній отримав широке застосування завдяки своїм чудовим властивостям, легкій вазі та теплопровідності. Однак при використанні в літаках це може спричинити корозію та прилипання, що погіршує безпеку. Щоб вирішити цю проблему, анодування використовується для покращення стійкості алюмінію до корозії та адгезії. У цьому дослідженні матеріал AA2024 був анодований за допомогою процесу анодування бором і сірчаною кислотою, а потім процес герметизації за допомогою оцтової кислоти. Цей процес герметизації утворює оксидний шар на поверхні алюмінію, що знижує швидкість корозії. Дослідження вивчало вплив напруги та часу анодування на результати анодування бором і сірчаною кислотою за допомогою кількісних і якісних вимірювань, включаючи корозійну стійкість, потенціодинамічну поляризацію, скануючу електронну мікроскопію і енергодисперсійну рентгенівську спектроскопію. Результати показали, що зразки, анодовані з прокладкою, можуть знизити швидкість корозії до 85 % порівняно зі зразками без прокладки та підкладки. Найбільш істотне зниження швидкості корозії відбулося при напрузі анодування 10 В і часу анодування 15 хв. Результати потенціодинамічних випробувань показали, що графік Тафеля під час герметизації лежить у катодній області, де щільність струму корозії зменшується зі збільшенням напруги. Спостереження скануючої електронної мікроскопії показали, що процес анодування може створити шар оксиду на поверхні зразків, тоді як процес запечатування створює гладку поверхню. Аналіз енергодисперсійною рентгенівською спектроскопією показав, що оксидна сполука утворилася у стані оксидного зв’язку після того, як поверхня зразка була піддана герметизуючій обробці. Загалом дослідження демонструє ефективність анодування бором і сірчаною кислотою для підвищення стійкості до корозії та підкреслює важливість урахування параметрів анодування

Спонсор дослідження

- This research is supported by the Mechanical Engineering Laboratory, Hasanuddin University.

Посилання

- Prasad, N. E., Wanhill, R. J. H. (Eds.) (2017). Aerospace Materials and Material Technologies. Springer. doi: https://doi.org/10.1007/978-981-10-2134-3

- Tunes, M. A., Stemper, L., Greaves, G., Uggowitzer, P. J., Pogatscher, S. (2020). Prototypic Lightweight Alloy Design for Stellar‐Radiation Environments. Advanced Science, 7 (22), 2002397. doi: https://doi.org/10.1002/advs.202002397

- Iglesias-Rubianes, L., Garcia-Vergara, S. J., Skeldon, P., Thompson, G. E., Ferguson, J., Beneke, M. (2007). Cyclic oxidation processes during anodizing of Al–Cu alloys. Electrochimica Acta, 52 (24), 7148–7157. doi: https://doi.org/10.1016/j.electacta.2007.05.052

- Hamsir, H., Sutresman, O., Arsyad, H., Syahid, M., Widyianto, A. (2022). Suppression of corrosion on stainless steel 303 with automatic impressed current cathodic protection (a-ICCP) method in simulated seawater. Eastern-European Journal of Enterprise Technologies, 6 (12 (120)), 13–21. doi: https://doi.org/10.15587/1729-4061.2022.267264

- Subbotinа, V., Sоbоl, O., Belozerov, V., Subbotin, A., Smyrnova, Y. (2020). A study of the phase-structural engineering possibilities of coatings on D16 alloy during micro-arc oxidation in electrolytes of different types. Eastern-European Journal of Enterprise Technologies, 4 (12 (106)), 14–23. doi: https://doi.org/10.15587/1729-4061.2020.209722

- Polmear, I. J. (2004). Aluminium Alloys – A Century of Age Hardening. Materials Forum. Available at: https://www.researchgate.net/publication/279898292_Aluminium_Alloys_-_A_Century_of_Age_Hardening

- Bensalah, W., Feki, M., Wery, M., Ayedi, H. F. (2011). Chemical dissolution resistance of anodic oxide layers formed on aluminum. Transactions of Nonferrous Metals Society of China, 21 (7), 1673–1679. doi: https://doi.org/10.1016/s1003-6326(11)60913-8

- Stevenson, M. F. (2013). Anodizing.

- Fratila-Apachitei, L. E., Apachitei, I., Duszczyk, J. (2006). Thermal effects associated with hard anodizing of cast aluminum alloys. Journal of Applied Electrochemistry, 36 (4), 481–486. doi: https://doi.org/10.1007/s10800-005-9102-y

- Poinern, G. E. J., Ali, N., Fawcett, D. (2011). Progress in Nano-Engineered Anodic Aluminum Oxide Membrane Development. Materials, 4 (3), 487–526. doi: https://doi.org/10.3390/ma4030487

- Zhang, L., Thompson, G. E., Curioni, M., Skeldon, P. (2013). Anodizing of Aluminum in Sulfuric Acid/Boric Acid Mixed Electrolyte. Journal of The Electrochemical Society, 160 (4), C179–C184. doi: https://doi.org/10.1149/2.032306jes

- Sanyal, S., Kim, T., Rabelo, M., Pham, D. P., Yi, J. (2022). Application of noble cerium-based anti-corrosion sealing coating approach applied on electrical insulators installed in industrial regions. Royal Society Open Science, 9 (4). doi: https://doi.org/10.1098/rsos.211786

- Haruna, T., Ikeda, T., Miyazaki, M., Nishimoto, A., Hirohata, Y. (2015). Correlation between Bound Water and Stability of Anodic Oxide Film on Aluminum. MATERIALS TRANSACTIONS, 56 (12), 2000–2005. doi: https://doi.org/10.2320/matertrans.l-m2015831

- Shen, Y. Z., Li, H. G., Tao, H. J., Ling, J., Wang, T., Tao, J. (2015). Effect of anodic films on corrosion resistance and fatigue crack initiator of 2060-T8 Al-Li alloy. International Journal of Electrochemical Science, 10 (1), 938–946. Available at: https://www.researchgate.net/publication/281996844_Effect_of_anodic_films_on_corrosion_resistance_and_fatigue_crack_initiator_of_2060-T8_Al-Li_alloy

- Veys-Renaux, D., Chahboun, N., Rocca, E. (2016). Anodizing of multiphase aluminium alloys in sulfuric acid: in-situ electrochemical behaviour and oxide properties. Electrochimica Acta, 211, 1056–1065. doi: https://doi.org/10.1016/j.electacta.2016.06.131

- Mukhurov, N. I., Zhvavyi, S. P., Terekhov, S. N., Panarin, A. Yu., Kotova, I. F., Pershukevich, P. P. et al. (2008). Influence of electrolyte composition on photoluminescent properties of anodic aluminum oxide. Journal of Applied Spectroscopy, 75 (2), 214–218. doi: https://doi.org/10.1007/s10812-008-9026-5

- Pooladi, R., Rezaei, H., Aezami, M., Sayyar, M. R. (2009). Fabrication of anodic aluminum oxide nanotemplate and investigation of their anodization parameters. Transactions of the Indian Institute of Metals, 62 (3), 241–244. doi: https://doi.org/10.1007/s12666-009-0026-9

- Fotovvati, B., Namdari, N., Dehghanghadikolaei, A. (2019). On Coating Techniques for Surface Protection: A Review. Journal of Manufacturing and Materials Processing, 3 (1), 28. doi: https://doi.org/10.3390/jmmp3010028

- Wang, R., Wang, L., He, C., Lu, M., Sun, L. (2019). Studies on the sealing processes of corrosion resistant coatings formed on 2024 aluminium alloy with tartaric-sulfuric anodizing. Surface and Coatings Technology, 360, 369–375. doi: https://doi.org/10.1016/j.surfcoat.2018.12.092

- Gonzalez, J. A., Lopez, V., Otero, E., Bautista, A., Lizarbe, R., Barba, C., Baldonedo, J. L. (1997). Overaging of sealed and unsealed aluminium oxide films. Corrosion Science, 39 (6), 1109–1118. doi: https://doi.org/10.1016/s0010-938x(97)00019-x

- Yu, S., Wang, L., Wu, C., Feng, T., Cheng, Y., Bu, Z., Zhu, S. (2020). Studies on the corrosion performance of an effective and novel sealing anodic oxide coating. Journal of Alloys and Compounds, 817, 153257. doi: https://doi.org/10.1016/j.jallcom.2019.153257

- Zhang, L. M., Zhang, S. D., Ma, A. L., Hu, H. X., Zheng, Y. G., Yang, B. J., Wang, J. Q. (2018). Influence of sealing treatment on the corrosion behavior of HVAF sprayed Al-based amorphous/nanocrystalline coating. Surface and Coatings Technology, 353, 263–273. doi: https://doi.org/10.1016/j.surfcoat.2018.08.086

- Hu, N., Dong, X., He, X., Browning, J. F., Schaefer, D. W. (2015). Effect of sealing on the morphology of anodized aluminum oxide. Corrosion Science, 97, 17–24. doi: https://doi.org/10.1016/j.corsci.2015.03.021

- Kocabaş, M., Örnek, C., Curioni, M., Cansever, N. (2019). Nickel fluoride as a surface activation agent for electroless nickel coating of anodized AA1050 aluminum alloy. Surface and Coatings Technology, 364, 231–238. doi: https://doi.org/10.1016/j.surfcoat.2019.03.003

- Hao, X.-L., Zhao, N., Jin, H.-H., Ma, W., Zhang, D.-H. (2020). Nickel-free sealing technology for anodic oxidation film of aluminum alloy at room temperature. Rare Metals, 40 (4), 968–974. doi: https://doi.org/10.1007/s12598-020-01410-8

- Whelan, M., Cassidy, J., Duffy, B. (2013). Sol–gel sealing characteristics for corrosion resistance of anodised aluminium. Surface and Coatings Technology, 235, 86–96. doi: https://doi.org/10.1016/j.surfcoat.2013.07.018

- Capelossi, V. R., Poelman, M., Recloux, I., Hernandez, R. P. B., de Melo, H. G., Olivier, M. G. (2014). Corrosion protection of clad 2024 aluminum alloy anodized in tartaric-sulfuric acid bath and protected with hybrid sol–gel coating. Electrochimica Acta, 124, 69–79. doi: https://doi.org/10.1016/j.electacta.2013.09.004

- Huang, T.-C., Lin, C.-Y., Liao, K.-C. (2022). Sealing performance assessments of PTFE rotary lip seals based on the elasto-hydrodynamic analysis with the modified archard wear model. Tribology International, 176, 107917. doi: https://doi.org/10.1016/j.triboint.2022.107917

- Abd-Elnaiem, A. M., Abbady, G., Ali, D., Asafa, T. B. (2019). Influence of anodizing voltage and electrolyte concentration on Al-1 wt% Si thin films anodized in H2SO4. Materials Research Express, 6 (8), 086468. doi: https://doi.org/10.1088/2053-1591/ab2848

- Park, J., Son, K., Lee, J., Kim, D., Chung, W. (2021). Effects of Anodizing Conditions on Thermal Properties of Al 20XX Alloys for Aircraft. Symmetry, 13 (3), 433. doi: https://doi.org/10.3390/sym13030433

- Araoyinbo, A. O., Noor, A. F. M., Sreekantan, S., Aziz, A. (2010). Voltage Effect on Electrochemical Anodization of Aluminum at Ambient Temperature. International Journal of Mechanical and Materials Engineering, 5 (1), 53–58. Available at: https://www.researchgate.net/publication/265811751_Voltage_effect_on_electrochemical_anodization_of_aluminum_at_ambient_temperature

##submission.downloads##

Опубліковано

Як цитувати

Номер

Розділ

Ліцензія

Авторське право (c) 2023 Muhammad Zuchry, Ilyas Renreng, Hairul Arsyad, Lukmanul Hakim Arma, Agus Widyianto

Ця робота ліцензується відповідно до Creative Commons Attribution 4.0 International License.

Закріплення та умови передачі авторських прав (ідентифікація авторства) здійснюється у Ліцензійному договорі. Зокрема, автори залишають за собою право на авторство свого рукопису та передають журналу право першої публікації цієї роботи на умовах ліцензії Creative Commons CC BY. При цьому вони мають право укладати самостійно додаткові угоди, що стосуються неексклюзивного поширення роботи у тому вигляді, в якому вона була опублікована цим журналом, але за умови збереження посилання на першу публікацію статті в цьому журналі.

Ліцензійний договір – це документ, в якому автор гарантує, що володіє усіма авторськими правами на твір (рукопис, статтю, тощо).

Автори, підписуючи Ліцензійний договір з ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР», мають усі права на подальше використання свого твору за умови посилання на наше видання, в якому твір опублікований. Відповідно до умов Ліцензійного договору, Видавець ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР» не забирає ваші авторські права та отримує від авторів дозвіл на використання та розповсюдження публікації через світові наукові ресурси (власні електронні ресурси, наукометричні бази даних, репозитарії, бібліотеки тощо).

За відсутності підписаного Ліцензійного договору або за відсутністю вказаних в цьому договорі ідентифікаторів, що дають змогу ідентифікувати особу автора, редакція не має права працювати з рукописом.

Важливо пам’ятати, що існує і інший тип угоди між авторами та видавцями – коли авторські права передаються від авторів до видавця. В такому разі автори втрачають права власності на свій твір та не можуть його використовувати в будь-який спосіб.