Analysis of the thermal shock and fouling resistance of the Kalimantan zircon based hybrid composite ceramic coating in boiler environment

DOI:

https://doi.org/10.15587/1729-4061.2023.281807Keywords:

zircon sand ceramic coating, purified zircon ceramic coating, lubricant, slurry spray, thermal shock, fouling resistanceAbstract

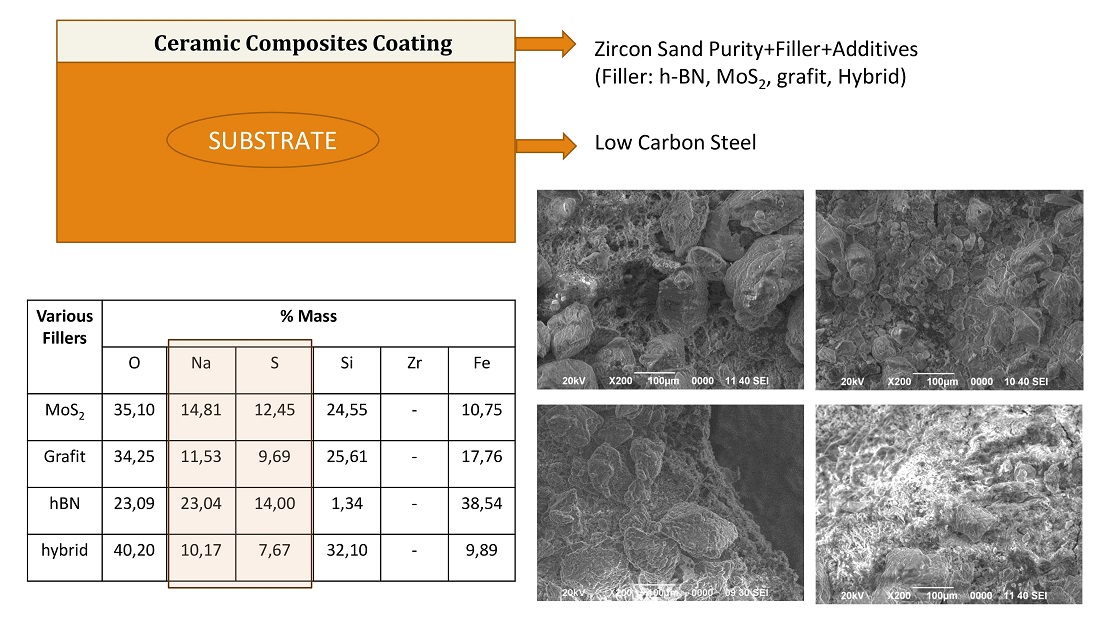

Power plant boilers operate at relatively high temperatures and pressures. As they are prone to material degradation, fouling and scaling, the materials used must have good thermal and chemical resistance. Coating material is one of the solutions to problems that exist in boilers. In this study, the basic coating material used came from local mineral resources, namely Kalimantan zircon sand and zirconia that had been purified from zircon sand. And there is the addition of filler as a coating reinforcement so that the coating properties become better. The variables of this study are variations of filler materials that have lubricating properties such as hBN, MoS2, graphite and a mixture of the three fillers (hybrid). The coating method used is slurry spray coating and then sintering at 600 °C. The main coating parameter tests carried out were thermal shock and anti-fouling resistance. From the research results, it was found that the purification of Zircon Sand resulted in an increase in Zirconia content from 59 % to 68 %. From the results of the thermal shock resistance and anti-fouling tests, it was found that the coating with purified zircon has better thermal shock resistance while the fouling resistance is not significantly different from unrefined zircon sand, so it is necessary to develop a zircon purification process to obtain a higher ZrO2 content. For filler variations, the hybrid filler produces a coating with better thermal shock and anti-fouling resistance so that it can be used for optimizing ceramic composite coatings

Supporting Agency

- The Authors would like to thank to PDD Funding of Kemenristekdikti who have funded this research.

References

- Ahmed, G. M. S., Mohiuddin, Mohd. V., Sultana, S., Dora, H. K., Singh, V. D. (2015). Microstructure Analysis and Evaluation of Mechanical Properties of Nickel Based Super Alloy CCA617. Materials Today: Proceedings, 2 (4-5), 1260–1269. doi: https://doi.org/10.1016/j.matpr.2015.07.041

- Mabruri, E., Syahlan, Z. A., Sahlan, Prifiharni, S., Anwar, M. S., Chandra, S. A. et al. (2017). Influence of Austenitizing Heat Treatment on the Properties of the Tempered Type 410-1Mo Stainless Steel. IOP Conference Series: Materials Science and Engineering, 202, 012085. doi: https://doi.org/10.1088/1757-899x/202/1/012085

- Müller-Steinhagen, H., Malayeri, M. R., Watkinson, A. P. (2011). Heat Exchanger Fouling: Mitigation and Cleaning Strategies. Heat Transfer Engineering, 32 (3-4), 189–196. doi: https://doi.org/10.1080/01457632.2010.503108

- Gomes da Cruz, L., Ishiyama, E. M., Boxler, C., Augustin, W., Scholl, S., Wilson, D. I. (2015). Value pricing of surface coatings for mitigating heat exchanger fouling. Food and Bioproducts Processing, 93, 343–363. doi: https://doi.org/10.1016/j.fbp.2014.05.003

- Santos, O., Anehamre, J., Wictor, C., Tornqvist, A., Nilsson, M. (2013). Minimizing crude oil fouling by modifying the surface of heat exchangers with a flexible ceramic coating. In Proc. Heat Exchanger Fouling & Cleaning X, 79–84.

- Wang, J., Yuan, Y., Chi, Z., Zhang, G. (2018). Development and application of anti-fouling ceramic coating for high-sodium coal-fired boilers. Journal of the Energy Institute, 91 (6), 962–969. doi: https://doi.org/10.1016/j.joei.2017.08.003

- Zhang, Z., Chen, H., Wang, Y., Wang, G., Li, L., Zhong, M., Bai, H. (2022). Effect of sodium silicate binder on the performance of ceramic coatings on copper prepared by the slurry method. Surface and Coatings Technology, 448, 128868. doi: https://doi.org/10.1016/j.surfcoat.2022.128868

- Hirvonen, A., Nowak, R., Yamamoto, Y., Sekino, T., Niihara, K. (2006). Fabrication, structure, mechanical and thermal properties of zirconia-based ceramic nanocomposites. Journal of the European Ceramic Society, 26 (8), 1497–1505. doi: https://doi.org/10.1016/j.jeurceramsoc.2005.03.232

- Fazel, M., Jazi, M. R. G., Bahramzadeh, S., Bakhshi, S. R., Ramazani, M. (2014). Effect of solid lubricant particles on room and elevated temperature tribological properties of Ni–SiC composite coating. Surface and Coatings Technology, 254, 252–259. doi: https://doi.org/10.1016/j.surfcoat.2014.06.027

- Kumar, R., Antonov, M. (2021). Self-lubricating materials for extreme temperature tribo-applications. Materials Today: Proceedings, 44, 4583–4589. doi: https://doi.org/10.1016/j.matpr.2020.10.824

- Sun, X., Zhang, J., Pan, W., Wang, W., Tang, C. (2023). A review on the preparation and application of BN composite coatings. Ceramics International, 49 (1), 24–39. doi: https://doi.org/10.1016/j.ceramint.2022.10.259

- Mischke, P. (2014). Film Formation: in Modern Paint Systems. Hannover, Germany: Vincentz Network. doi: https://doi.org/10.1515/9783748602262

- Wu, Z., Li, S., Zhang, P., Wang, C., Deng, C., Mao, J., Li, W., Tu, X. (2022). Controllable in-situ synthesis of MoS2/C in plasma-sprayed YSZ coatings: Microstructure, mechanical and tribological properties. Surface and Coatings Technology, 448, 128895. doi: https://doi.org/10.1016/j.surfcoat.2022.128895

- Tuo, Y., Yang, Z., Guo, Z., Chen, Y., Hao, J., Zhao, Q. et al. (2023). Pore structure optimization of MoS2/Al2O3 self-lubricating ceramic coating for improving corrosion resistance. Vacuum, 207, 111687. doi: https://doi.org/10.1016/j.vacuum.2022.111687

- Marcinauskas, L., Mathew, J. S., Milieška, M., Aikas, M., Kalin, M. (2023). Influence of graphite content on the tribological properties of plasma sprayed alumina-graphite coatings. Surfaces and Interfaces, 38, 102763. doi: https://doi.org/10.1016/j.surfin.2023.102763

- Eichler, J., Lesniak, C. (2008). Boron nitride (BN) and BN composites for high-temperature applications. Journal of the European Ceramic Society, 28 (5), 1105–1109. doi: https://doi.org/10.1016/j.jeurceramsoc.2007.09.005

- Zhao, W., Pan, J., Fang, Y., Che, X., Wang, D., Bu, K., Huang, F. (2018). Metastable MoS2 : Crystal Structure, Electronic Band Structure, Synthetic Approach and Intriguing Physical Properties. Chemistry - A European Journal, 24 (60), 15942–15954. doi: https://doi.org/10.1002/chem.201801018

- Jara, A. D., Betemariam, A., Woldetinsae, G., Kim, J. Y. (2019). Purification, application and current market trend of natural graphite: A review. International Journal of Mining Science and Technology, 29 (5), 671–689. doi: https://doi.org/10.1016/j.ijmst.2019.04.003

- Lee, K. N., Waters, D. L., Puleo, B. J., Garg, A., Jennings, W. D., Costa, G., Sacksteder, D. E. (2020). Development of oxide-based High temperature environmental barrier coatings for ceramic matrix composites via the slurry process. Journal of the European Ceramic Society, 41 (2), 1639–1653. doi: https://doi.org/10.1016/j.jeurceramsoc.2020.10.012

- Wang, J., Yuan, Y., Chi, Z., Zhang, G. (2018). High-temperature sulfur corrosion behavior of h-BN-based ceramic coating prepared by slurry method. Materials Chemistry and Physics, 206, 186–192. doi: https://doi.org/10.1016/j.matchemphys.2017.12.025

- Jiapei, J., Yongnan, C., Chaoping, J., Yong, Z., Qinyang, Z., Zhen, Z. et al. (2022). Composite ceramic coating with enhanced thermal shock resistance formed by the in-situ synthesis of nano-ZrO2. Ceramics International, 48 (8), 10629–10637. doi: https://doi.org/10.1016/j.ceramint.2021.12.277

- Liu, Q., Hu, X. P., Zhu, W., Liu, G. L., Guo, J. W., Bin, J. (2022). Thermal shock performance and failure behavior of Zr6Ta2O17-8YSZ double-ceramic-layer thermal barrier coatings prepared by atmospheric plasma spraying. Ceramics International, 48 (17), 24402–24410. doi: https://doi.org/10.1016/j.ceramint.2022.05.046

- Sigaroodi, M. R. J., Poursaeidi, E., Rahimi, J., Jamalabad, Y. Y. (2023). Heat treatment effect on coating shock resistance of thermal barrier coating system with different types of bond coat. Journal of the European Ceramic Society, 43 (8), 3658–3675. doi: https://doi.org/10.1016/j.jeurceramsoc.2023.01.035

- Cañas, E., Rosado, E., Alcázar, C., Orts, M. J., Moreno, R., Sánchez, E. (2022). Challenging zircon coatings by suspension plasma spraying. Journal of the European Ceramic Society, 42 (10), 4369–4376. doi: https://doi.org/10.1016/j.jeurceramsoc.2022.03.049

- Barish, J. A., Goddard, J. M. (2013). Anti-fouling surface modified stainless steel for food processing. Food and Bioproducts Processing, 91 (4), 352–361. doi: https://doi.org/10.1016/j.fbp.2013.01.003

- Ishiyama, E. M., Paterson, W. R., Wilson, D. I. (2008). Thermo-hydraulic channelling in parallel heat exchangers subject to fouling. Chemical Engineering Science, 63 (13), 3400–3410. doi: https://doi.org/10.1016/j.ces.2008.04.008

- Ayala, L. (2015). Technical handbook on zirconium and zirconium compounds. Zircon Industry Association.

- Musyarofah, Lestari, N. D., Nurlaila, R., Muwwaqor, N. F., Triwikantoro, Pratapa, S. (2019). Synthesis of high-purity zircon, zirconia, and silica nanopowders from local zircon sand. Ceramics International, 45 (6), 6639–6647. doi: https://doi.org/10.1016/j.ceramint.2018.12.152

- Yuhelda, Y., Amalia, D., Nugraha, E. P. (2017). Processing zirconia through zircon sand smelting with NaOH as a flux. Indonesian Mining Journal, 19 (1), 39–49. doi: https://doi.org/10.30556/imj.vol19.no1.2016.364

- Yamagata, C., Andrade, J. B., Ussui, V., de Lima, N. B., Paschoal, J. O. A. (2008). High Purity Zirconia and Silica Powders via Wet Process: Alkali Fusion of Zircon Sand. Materials Science Forum, 591-593, 771–776. doi: https://doi.org/10.4028/www.scientific.net/msf.591-593.771

- Ray, H. S., Ghosh, A. (2010). Principles of Extractive Metallurgy. New Delhi: New Age International (P) Limites Publisher.

- Mutimmah, Yuswono, S., Akbar, D. W., Nugroho, T. P., Rahman, Nofrizal, R., Ikono, Siswanto, Rochman, N. T. (2013). Optimization of Zirconia Extraction Made from Silicate Zircon Sand Through Base Reduction. Proceedings of Semirata FMIPA, University of Lampung, 401–404.

- Sarkar, M., Mandal, N. (2022). Solid lubricant materials for high temperature application: A review. Materials Today: Proceedings, 66, 3762–3768. doi: https://doi.org/10.1016/j.matpr.2022.06.030

- Bittmann, B., Haupert, F., Schlarb, A. K. (2009). Ultrasonic dispersion of inorganic nanoparticles in epoxy resin. Ultrasonics Sonochemistry, 16 (5), 622–628. doi: https://doi.org/10.1016/j.ultsonch.2009.01.006

- Billotte, C., Fotsing, E. R., Ruiz, E. (2017). Optimization of Alumina Slurry for Oxide-Oxide Ceramic Composites Manufactured by Injection Molding. Advances in Materials Science and Engineering, 2017, 1–9. doi: https://doi.org/10.1155/2017/2748070

- Tajima, R., Kato, Y. (2011). Comparison of threshold algorithms for automatic image processing of rice roots using freeware ImageJ. Field Crops Research, 121 (3), 460–463. doi: https://doi.org/10.1016/j.fcr.2011.01.015

- Nguyen, M., Bang, J., Kim, Y., Bin, A., Hwang, K., Pham, V.-H., Kwon, W.-T. (2018). Anti-Fouling Ceramic Coating for Improving the Energy Efficiency of Steel Boiler Systems. Coatings, 8 (10), 353. https://doi.org/10.3390/coatings8100353

- Poernomo, H. (2012). Zirconium General Information. Yogyakarta: National Nuclear Energy Agency, Center for Material Process and Accelerator Technology.

- Donachie, M. (2000). Titanium: A Technical Guide. ASM International. doi: https://doi.org/10.31399/asm.tb.ttg2.9781627082693

- Xiao, K., Xue, W., Li, Z., Wang, J., Li, X., Dong, C. et al. (2018). Effect of sintering temperature on the microstructure and performance of a ceramic coating obtained by the slurry method. Ceramics International, 44 (10), 11180–11186. doi: https://doi.org/10.1016/j.ceramint.2018.03.147

- Lee, S.-H., Themelis, N. J., Castaldi, M. J. (2007). High-Temperature Corrosion in Waste-to-Energy Boilers. Journal of Thermal Spray Technology, 16 (1), 104–110. doi: https://doi.org/10.1007/s11666-006-9005-4

- Cheng, Y., Miu, L., Hou, B. (1990). Fatigue Strength[M]. Beijing: China Railway Press, 11.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Yulinda Lestari, Anne Zulfia, Muhammad Ardin, Septian Adi Chandra, Fauzi Widyawati, Efendi Mabruri

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.