Improving the fire resistance of wooden structures by a combined method

DOI:

https://doi.org/10.15587/1729-4061.2023.283154Keywords:

wooden structures, fire, components, fire-protection, coating, mass loss, flame combustion, flame retardant, synergismAbstract

The flammability of wood largely limits the use of wooden structures in modern construction. Therefore, there is a need to protect the wooden structures of buildings and structures from fire danger.

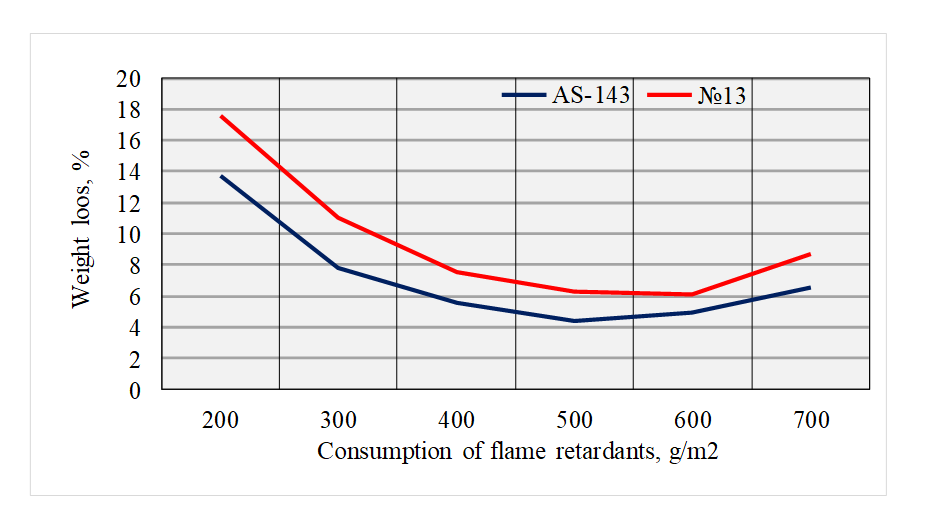

Ammophos-A, ammonium sulfate, expanded perliteб and epoxy were used to develop the fire-retardant surface coating. The experiments were carried out by changing the amount of one of these components in the composition, leaving the others constant. At the same time, fire hazard indicators were controlled parameters. In this way, the optimal ratios of the components of the flame-retardant composition were established, which were: 15:15:10:50 (wt.%), respectively, ammophos-A, ammonium sulfate, expanded perlite, epoxy resin, further designated flame retardant AS-143. The test parameters of structural samples treated with this flame retardant at a consumption of 400–500 g/m2 were: weight loss 4.0–5.0 %, flame burning time 11–18 s, flameless 19–23 s. The effectiveness of the flame retardant AS-143 was established in comparison with flame retardant No. 13, which, according to the weight loss of the samples, was 43.2 %.

The essence of the results is explained by the correct selection of chemical compounds and their component ratio in the fire-retardant composition, which exhibit a synergistic character during the combustion of wooden structures.

At the next stage, in addition to surface treatment of wooden structures, they were faced with fire-resistant plasterboard sheets. Fire tests were carried out under field conditions for 30 minutes, the results of which were: the length of flame propagation over the surface of the samples was 456–678 mm; flame propagation speed 0.015–0.023 m/min.

The data indicate that wooden structures treated in a combined way belong to group I of fire protection efficiency. These structures can be safely used in buildings and structures, especially with enclosing, attic, or attic types

References

- Rafili, Sh. F. (2021). Ncrease fire resistance of wooden constructions of constructions of special purpose. Uchenye zapiski AzTU, 1, 21–26. Available at: https://drive.google.com/file/d/1T6dP0aGpKAlrIzd943dAO496ZZxcj6Yw/view

- Frangi, A., Fontana, M. (2010). Fire safety of multistorey timber buildings. Proceedings of the Institution of Civil Engineers - Structures and Buildings, 163 (4), 213–226. doi: https://doi.org/10.1680/stbu.2010.163.4.213

- Brushlinskiy, N. N., Sokolov, S. V. (2020). How much is the fire “cost” in the modern world? Pozharovzryvobezopasnost/Fire and Explosion Safety, 29 (1), 79–88. doi: https://doi.org/10.18322/pvb.2020.29.01.79-88

- Gusev, A. I., Paznikova, S. N., Kozhevnikova, N. S. (2006). Povyshenie ognestoykosti stroitel'nykh derevyannykh konstruktsiy. Pozharovzryvobezopasnost/Fire and Explosion Safety, 15 (3), 30–35.

- Leonovich, A. A. (1984). Vozmozhnosti khimicheskoy ognezaschity drevesnykh materialov. Mater. mezhd. konf. «Teoreticheskie i prakticheskie aspekty ognezaschity drevesnykh materialov». Riga, 23–28.

- Snegirev, A. Yu., Talalov, V. A., Stepanov, V. V., Harris, J. N. (2013). A new model to predict pyrolysis, ignition and burning of flammable materials in fire tests. Fire Safety Journal, 59, 132–150. doi: https://doi.org/10.1016/j.firesaf.2013.03.012

- Mustafaev, I. I., Yakhyaev, A. B., Refili, S. F. (2020). Increasing fire resistance of bearing wood roof structures of buildings. Vestnik IAELPS, 25 (2), 37–42.

- GOST 25130-82. Intumescent fire protective wood coating. Technical requirements. Available at: https://docs.cntd.ru/document/1200000332

- Eremina, T. Yu., Gravit, M. V., Dmitrieva, Yu. N. (2012). Retseptury ognezaschitnykh vspuchivayuschikhsya pokrytiy na osnove epoksidnykh smol. Pozharovzryvobezopasnost/Fire and Explosion Safety, 7, 52–56.

- Vspenivayuschiysya ogneupornyy sostav «Fayreks-500». Available at: https://www.infrahim.ru/products/2170/

- Ognezaschitniy sostav Defender W (kraska VD-AK-222 Defender W). Available at: https://www.infrahim.ru/products/2086/

- Xie, W., Chen, H., He, D., Zhang, Y., Fu, L., Ouyang, J., Yang, H. (2019). An emerging mineral-based composite flame retardant coating: Preparation and enhanced fireproof performance. Surface and Coatings Technology, 367, 118–126. doi: https://doi.org/10.1016/j.surfcoat.2019.03.073

- Mykhalichko, B., Lavrenyuk, H. (2022). Flame Protection Technologies for Wood: Developing and Testing for Fire of Timbers with a Flame-retardant Coating Based on the Epoxy-amine Composite Modified by Copper(II) Hexafluorosilicate. Periodica Polytechnica Chemical Engineering, 66 (2), 304–312. doi: https://doi.org/10.3311/ppch.19050

- Pokrovskaya, E. N. (2018). Increase of strength of partially destroyed wood of monuments of wooden architecture. Vestnik MGSU, 11, 1305–1314. doi: https://doi.org/10.22227/1997-0935.2018.11.1305-1314

- Vakhitova, L. N. (2019). Fire retardant nanocoating for wood protection. Nanotechnology in Eco-Efficient Construction, 361–391. doi: https://doi.org/10.1016/b978-0-08-102641-0.00016-5

- Zmaha, M. I., Pozdieiev, S. V., Zmaha, Y. V., Nekora, O. V., Sidnei, S. O. (2021). Research of the behavioral of the wooden beams with fire protection lining under fire loading. IOP Conference Series: Materials Science and Engineering, 1021 (1), 012031. doi: https://doi.org/10.1088/1757-899x/1021/1/012031

- Cheng, X., Lu, D., Yue, K., Lu, W., Zhang, Z. (2022). Fire Resistance Improvement of Fast-Growing Poplar Wood Based on Combined Modification Using Resin Impregnation and Compression. Polymers, 14 (17), 3574. doi: https://doi.org/10.3390/polym14173574

- NPB 251-98. Fire retardant compositions and substances for wood. General requirementes. Test methods. URL: https://docs.cntd.ru/document/1200001870

- GOST 16363-98. Fire protective means for wood. Methods for determination of fire protective properties. Available at: https://docs.cntd.ru/document/1200003142

- GOST R 51032-97. Materialy stroitel'nye. Metod ispytaniya na rasprostranenie plameni. Available at: https://files.stroyinf.ru/Data1/4/4987/index.htm

- Maciulaitis, R., Grigonis, M., Malaiskiene, J. (2018). The impact of the aging of intumescent fire protective coatings on fire resistance. Fire Safety Journal, 98, 15–23. doi: https://doi.org/10.1016/j.firesaf.2018.03.007

- Lucherini, A., Giuliani, L., Jomaas, G. (2018). Experimental study of the performance of intumescent coatings exposed to standard and non-standard fire conditions. Fire Safety Journal, 95, 42–50. doi: https://doi.org/10.1016/j.firesaf.2017.10.004

- Eremina, T. Yu., Gravit, M. V., Dmitrieva, Yu. N. (2012). Naznachenie ognezaschitnykh vspuchivayuschiesya kompozitsiy na osnove epoksidnykh smol. Pozharovzryvobezopasnost/Fire and Explosion Safety, 8, 42–45.

- Janssens, M. L. (2004). Modeling of the thermal degradation of structural wood members exposed to fire. Fire and Materials, 28 (24), 199–207. doi: https://doi.org/10.1002/fam.848

- Aseeva, R., Serkov, B., Sivenkov, A. (2014). Fire Behavior and Fire Protection in Timber Buildings. Springer Series in Wood Science. doi: https://doi.org/10.1007/978-94-007-7460-5

- Merryweather, G., Spearpoint, M. J. (2009). Flame spread measurements on wood products using the ASTM E 1321 LIFT apparatus and a reduced scale adaptation of the cone calorimeter. Fire and Materials, 34 (3). 109–136. doi: https://doi.org/10.1002/fam.1001

- Khasanov, I. R. (2016). Features of fire safety of buildings of wooden structures. Пожаровзрывобезопасность, 25 (11), 51–60. doi: https://doi.org/10.18322/pvb.2016.25.11.51-60

- Rykov, R. I. (1983). Otsenka effektivnosti antipirenov dlya derevyannykh konstruktsiy. Lesnoy zhurnal, 5, 81–84.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Aydin Yakhyayev, Siyavush Gezelov, Ayten Gamidova, Shahmar Refili

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.