Performance optimization of radiator engine parameters during hard conditions by control charts monitoring and evaluating

DOI:

https://doi.org/10.15587/1729-4061.2023.285698Keywords:

optimization, Six Sigma technique, control chart, Box-Behnken, cooling fanAbstract

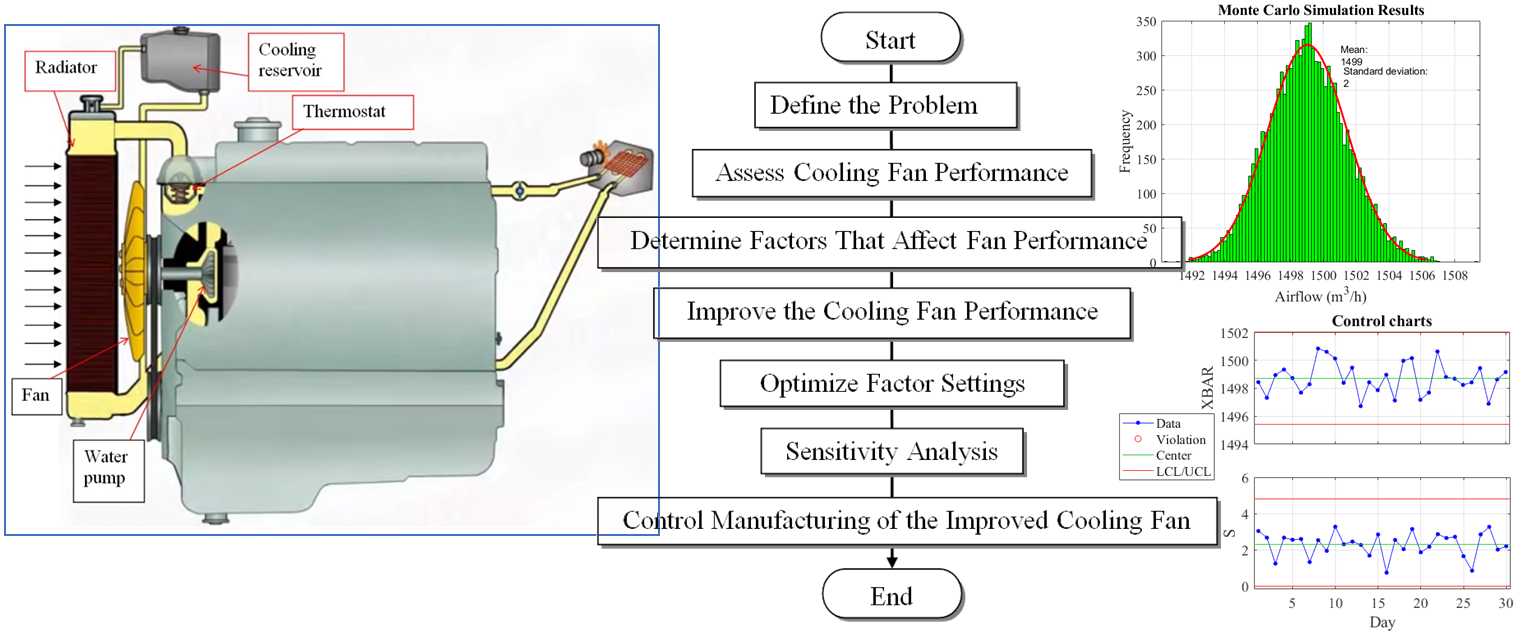

Recently, engine design and control systems have been developed using data-driven modeling techniques to specify the in-cylinder complicated combustion process. The cooling fan performance is highly influenced by several factors that are determined based on what is called (DOE) «design of experiments». These factors include blade tip clearance, pitch angle, distance from radiator. This work presents a method to improve a cooling fan performance of an engine by designing a Six Sigma technique using Control, Improve, Analyze, Measure, and Define (CIAMD). First, let’s assess the existing cooling fan performance and define its problem. Then, let’s specify the parameters that affect on fan performance to be optimized. Next, let’s conduct sensitivity analysis and evaluate manufacturing control of the developed cool Fan. The primary fan does not distribute air enough by the radiator to maintain the machine cool throughout hard circumstances. First, the work demonstrates how to develop an experiment to examine the influence of three performance elements: blade pitch angle, blade-tip clearance, and fan distance from the radiator. In order to improve the performance of the cooling fan, Box-Behnken design is adopted for testing quadratic (nonlinear) effects. It then indicates how to predict optimal quantities for every element, to produce a technique that makes airflows above the objective of 1486.6 m3/h when utilizing experimental measurements. Finally, it reveals how to operate simulations to confirm that this method creates airflow based on the specifications with more additional fans manufactured performance of 99.999 %. The results of S and X-bar control charts indicate that the manufacturing process is statistically under control

Supporting Agency

- All authors are acknowledging the Middle Technical University and University of Technology-Iraq for their assistance and support.

References

- Kaleli, A., Akolaş, H. İ. (2021). The design and development of a diesel engine electromechanical EGR cooling system based on machine learning-genetic algorithm prediction models to reduce emission and fuel consumption. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 236 (3), 1888–1902. doi: https://doi.org/10.1177/09544062211020045

- Wu, J., Liu, X., Shan, Y., He, T. (2018). Robustness optimization of engine mounting system based on Six Sigma and torque roll axis decoupling method. Proceedings of the Institution of Mechanical Engineers, Part D: Journal of Automobile Engineering, 233 (4), 1047–1060. doi: https://doi.org/10.1177/0954407018755247

- Nejlaoui, M., Alghafis, A., Sadig, H. (2022). Six sigma robust multi-objective design optimization of flat plate collector system under uncertain design parameters. Energy, 239, 121883. doi: https://doi.org/10.1016/j.energy.2021.121883

- Xiao, S., Li, Y., Rotaru, M., Sykulski, J. K. (2015). Six Sigma Quality Approach to Robust Optimization. IEEE Transactions on Magnetics, 51 (3), 1–4. doi: https://doi.org/10.1109/tmag.2014.2360435

- Ibrahim, A. M., Hendawy, H. A. M., Hassan, W. S., Shalaby, A., El-sayed, H. M. (2019). Six Sigma quality approach for HPLC-UV method optimization. Microchemical Journal, 144, 303–308. doi: https://doi.org/10.1016/j.microc.2018.09.023

- Madhani, P. M. (2020). Performance optimisation of retail Industry: Lean six sigma approach. ASBM Journal of Management, 13 (1), 74–91. Available at: https://ssrn.com/abstract=4002475

- Adeodu, A., Kanakana-Katumba, M. G., Rendani, M. (2021). Implementation of Lean Six Sigma for production process optimization in a paper production company. Journal of Industrial Engineering and Management, 14 (3), 661. doi: https://doi.org/10.3926/jiem.3479

- Abualsauod, E. H., Othman, A. M. (2019). Improving Online Quality Control in the Six Sigma Methodology Using a Multiobjective Optimization Approach. Industrial Engineering & Management Systems, 18 (2), 195–209. doi: https://doi.org/10.7232/iems.2019.18.2.195

- Shimoyama, K., Oyama, A., Fujii, K. (2008). Development of Multi-Objective Six Sigma Approach for Robust Design Optimization. Journal of Aerospace Computing, Information, and Communication, 5 (8), 215–233. doi: https://doi.org/10.2514/1.30310

- Abebe, M., Yoon, J., Kang, B.-S. (2020). Multi-Objective Six-Sigma Approach for Robust Optimization of Multi-Point Dieless Forming Process. International Journal of Precision Engineering and Manufacturing, 21 (10), 1791–1806. doi: https://doi.org/10.1007/s12541-020-00373-1

- Pariasa, I. I., Anam, M. A. S., Hardana, A. E. (2021). Sorbitol production optimization in B2B industry with six sigma approach. IOP Conference Series: Earth and Environmental Science, 733 (1), 012056. doi: https://doi.org/10.1088/1755-1315/733/1/012056

- Pereira, A. M. H., Silva, M. R., Domingues, M. A. G., Sá, J. C. (2019). Lean Six Sigma Approach to Improve the Production Process in the Mould Industry: a Case Study. Quality Innovation Prosperity, 23 (3), 103. doi: https://doi.org/10.12776/qip.v23i3.1334

- Tripathi, V., Chattopadhyaya, S., Mukhopadhyay, A. K., Sharma, S., Li, C., Singh, S., Saleem, W. et al. (2022). Recent Progression Developments on Process Optimization Approach for Inherent Issues in Production Shop Floor Management for Industry 4.0. Processes, 10 (8), 1587. doi: https://doi.org/10.3390/pr10081587

- Konikineni, P., Sundaram, V., Sathish, K., Thirukkotti, S. (2016). Optimization Solutions for Fan Shroud. SAE Technical Paper Series. doi: https://doi.org/10.4271/2016-01-1393

- A, R., Pang, L., Jiang, X., Qi, B., Shi, Y. (2021). Analysis and comparison of potential power and thermal management systems for high-speed aircraft with an optimization method. Energy and Built Environment, 2 (1), 13–20. doi: https://doi.org/10.1016/j.enbenv.2020.06.006

- Jun, S., Rhee, D.-H., Kang, Y. S., Chung, H., Kim, J.-H. (2022). Application of the Source Term Method and Fan-Shaped Hole for Cooling Performance Improvement in a High-Pressure Turbine. Energies, 15 (19), 6943. doi: https://doi.org/10.3390/en15196943

- Wang, T., Jagarwal, A., Wagner, J. R., Fadel, G. (2015). Optimization of an automotive radiator fan array operation to reduce power consumption. IEEE/ASME Transactions on Mechatronics, 20 (5), 2359–2369. doi: https://doi.org/10.1109/tmech.2014.2377655

- Akolaş, H. İ., Kaleli, A., Bakirci, K. (2020). Design and implementation of an autonomous EGR cooling system using deep neural network prediction to reduce NOx emission and fuel consumption of diesel engine. Neural Computing and Applications, 33 (5), 1655–1670. doi: https://doi.org/10.1007/s00521-020-05104-1

- Wan, L., Duan, L., Guo, Q., Duan, Y., Yu, N., Shangguan, W. (2019). Optimization of Engine Cooling Fan Tip Parameters. Huanan Ligong Daxue Xuebao/Journal of South China University of Technology (Natural Science).

- Liu, C., Zhang, R., Duan, M., Liu, K., Wang, W. (2019). A Study on the Matching of Air Inlet Grille Angle and Cooling Fan Speed in a Car. Automotive Engineering, 4, 388–394. doi: https://doi.org/10.19562/j.chinasae.qcgc.2019.04.005

- Ferreira, S. L. C., Bruns, R. E., Ferreira, H. S., Matos, G. D., David, J. M., Brandão, G. C. et al. (2007). Box-Behnken design: An alternative for the optimization of analytical methods. Analytica Chimica Acta, 597 (2), 179–186. doi: https://doi.org/10.1016/j.aca.2007.07.011

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Ali Fadhil Abduljabbar, Bashra Kadhim Oleiwi, Ahmad H. Sabry

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.