Application of the method of measuring deformation parameters under mechanical action on concrete beams using a fiber Bragg grating

DOI:

https://doi.org/10.15587/1729-4061.2023.285800Keywords:

fiber Bragg lattice, simulation, communication technologies optical fiber, Young's modulusAbstract

In order to study the patterns of deformation and change of concrete structures, studies of the fiber Bragg lattice in the form of a measuring sensor were carried out. Fiber optic sensors have several advantages: small size, resistance to electromagnetic interference, high sensitivity, wide range, simple structure, high reaction rate, corrosion resistance, geometrically versatile and resistant to external influences.

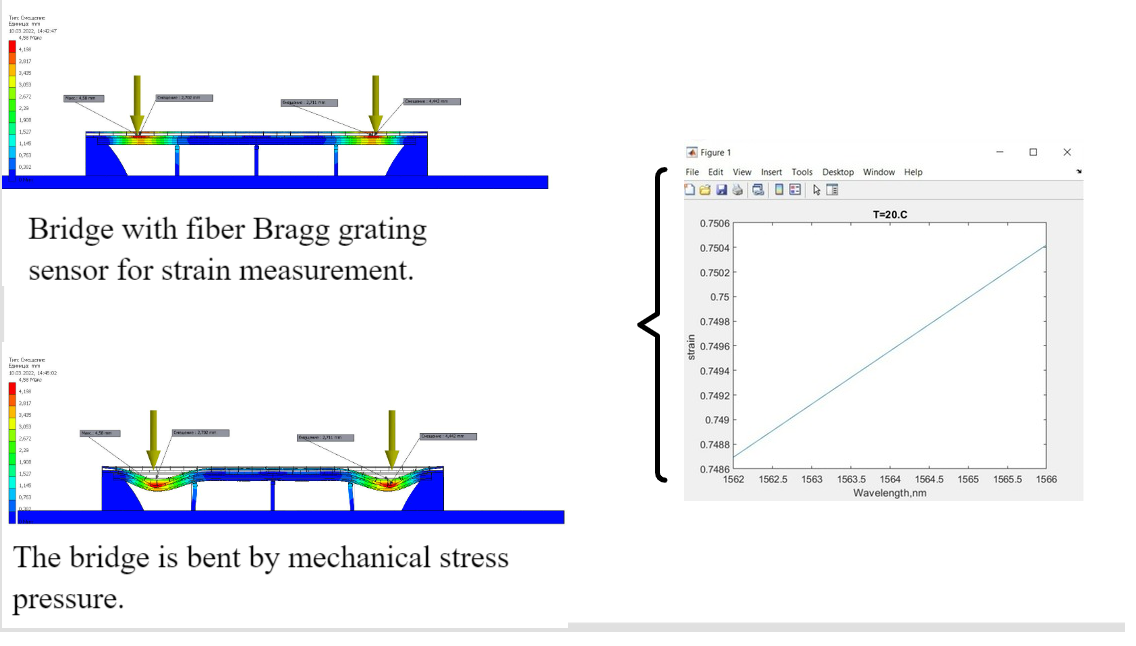

This work is related to the development of the characteristics and behavior of strain sensors acting on a fiber Bragg lattice using computer modeling. The work focuses on the analysis of the operational characteristics and behavior of strain sensors acting on the fiber Bragg lattice. The sensor is used to measure the deformation of an object whose resistance varies depending on the applied force. This is shown by an example of how a fiber Bragg lattice can demonstrate strain sensors. In the work, a simulation was carried out using a computer program to simulate the operation of a fiber Bragg lattice deformation sensor.

When measuring the deformation, calculations with the Young's modulus formulas were used for a more accurate calculation of the data. When measured, the wavelength left from 1662 nm to 1666 nm, as well as a constant temperature from 20 °C to 40 °C. The results show the following, the values of the Young's modulus are 23.25 Pa, the Poisson's ratio is 0.167 br, the modulus of elasticity at shear is 9.96444 Pa. And in this regard, the results of this work show: the first is that changes in the magnitude, position and shape of the deformation can reflect the dynamic evolutionary process of deformation during bending on the structure. The following is the deformation curve has a good corresponding relationship with the change in the applied pressure, which shows software modeling in different types of deformation.

The conclusion shows that the technology of monitoring fiber-Bragg lattice sensors has a good effect on internal deformation and control of mechanical stresses during model tests; it provides new methods and monitoring tools for model tests

References

- Jalil, M. A. B. (2021). Simulation of Fiber Bragg Grating Characteristics and Behaviors as Strain and Temperature Sensor. International Journal for Research in Applied Science and Engineering Technology, 9 (11), 1154–1161. doi: https://doi.org/10.22214/ijraset.2021.38883

- Lee, B. (2003). Review of the present status of optical fiber sensors. Optical Fiber Technology, 9 (2), 57–79. doi: https://doi.org/10.1016/s1068-5200(02)00527-8

- Mendez, A., Morse, T. F., Mendez, F. (1990). Applications Of Embedded Optical Fiber Sensors In Reinforced Concrete Buildings And Structures. SPIE Proceedings. doi: https://doi.org/10.1117/12.963084

- Yanbiao, L., Libo, Y., Qian, T. (2018). The 40 Years of Optical Fiber Sensors in China. Acta Optica Sinica, 38 (3), 0328001. doi: https://doi.org/10.3788/aos201838.0328001

- Kinet, D., Mégret, P., Goossen, K., Qiu, L., Heider, D., Caucheteur, C. (2014). Fiber Bragg Grating Sensors toward Structural Health Monitoring in Composite Materials: Challenges and Solutions. Sensors, 14 (4), 7394–7419. doi: https://doi.org/10.3390/s140407394

- Di Sante, R. (2015). Fibre Optic Sensors for Structural Health Monitoring of Aircraft Composite Structures: Recent Advances and Applications. Sensors, 15 (8), 18666–18713. doi: https://doi.org/10.3390/s150818666

- Wójcik, W., Kisała, P. (2009). The application of inverse analysis in strain distribution recovery using the fibre bragg grating sensors. Metrology and Measurement Systems. XVI (4), 649–660. Available at: http://www.metrology.pg.gda.pl/full/2009/M&MS_2009_649.pdf

- Orazaliyeva, S., Kadirbayeva, G., Chezhimbayeva, K. (2022). Evaluation of the effectiveness of the effect of photosensitization on the spectral characteristics of the fiber Bragg grating. Eastern-European Journal of Enterprise Technologies, 3 (5 (117)), 6–14. doi: https://doi.org/10.15587/1729-4061.2022.259033

- Feng, X., Zhou, J., Sun, C., Zhang, X., Ansari, F. (2013). Theoretical and Experimental Investigations into Crack Detection with BOTDR-Distributed Fiber Optic Sensors. Journal of Engineering Mechanics, 139 (12), 1797–1807. doi: https://doi.org/10.1061/(asce)em.1943-7889.0000622

- Wang, H., Zhou, Z., Huang, Y., Xiang, P., Ou, J. (2015). Strain transfer mechanism of quadrate-packaged FBG sensors embedded in rectangular structures. Journal of Civil Structural Health Monitoring, 5 (4), 469–480. doi: https://doi.org/10.1007/s13349-015-0131-x

- Nurzhaubayeva, G., Chezhimbayeva, K., Haris, N. (2022). Characterization of high impedance of multilayer coplanar waveguide transmission line design for integration with nanodevices. Eastern-European Journal of Enterprise Technologies, 4 (5 (118)), 6–14. doi: https://doi.org/10.15587/1729-4061.2022.263671

- Inaudi, D., Casanova, N., Kronenberg, P., Marazzi, S., Vurpillot, S. (1997). Embedded and surface-mounted fiber optic sensors for civil structural monitoring. SPIE Proceedings. doi: https://doi.org/10.1117/12.274668

- Haoyang, P., Qiong, L., Qing, Y., Guofeng, X., Haiwen, C., Ronghui, Q., Zujie, F. (2012). Analysis and Experimental Study of Inner Stress for Metallized Fiber Bragg Gratings. Chinese Journal of Lasers, 39 (3), 0305008. doi: https://doi.org/10.3788/cjl201239.0305008

- Dandan, P., Qingmei, S., Mingshun, J. et al. (2012). Fiber Bragg grating high-temperature sensing system based on improved support degree matrix model. Journal of Optoelectronics Laser, 23 (11), 2045–2051.

- Chunxiao, L., Youlong, Y., Jun, H., Hang, X. (2013). Measurement of the Natural Frequency of Bench Drill Based on Fiber Bragg Grating. Laser & Optoelectronics Progress, 50 (2), 020601. doi: https://doi.org/10.3788/lop50.020601

- Yiping, W., Ming, W., Xiaoqin, H. (2011). Transverse Pressure Sensor Based on the Polarization Properties of Fiber Grating. Chinese Journal of Lasers, 38 (4), 0405004. doi: https://doi.org/10.3788/cjl201138.0405004

- Qibiao, O., Qingke, Z., Zixiong, Q. et al. (2013). Application of coated long period fiber grating to measure the change of microrefractive index. Journal of Optoelectronics Laser, 24 (2), 323–328.

- Yongxing, G., Dongsheng, Z., Zhude, Z., Li, X., Fangdong, Z. (2013). Research Progress in Fiber-Bragg-Grating Accelerometer. Laser & Optoelectronics Progress, 50 (6), 060001. doi: https://doi.org/10.3788/lop50.060001

- Varzhel’, S. V. (2015). Volokonnye Breggovskie reshetki [Fiber Bragg Gratings]. Sankt-Peterburg: Universitet ITMO.

- Vasil’ev, S. A., Medvedkov, O. I., Korolev, I. G., Bozhkov, A. S., Kurkov, A. S., Dianov, E. M. (2005). Fibre gratings and their applications. Quantum Electronics, 35 (12), 1085–1103. doi: https://doi.org/10.1070/qe2005v035n12abeh013041

- Nureev, I. I. (2016). Radiophotonics amplitude-phase interrogation methods of complexed sensors based on fiber Bragg gratings. Engineering Journal of Don, 2. Available at: http://ivdon.ru/en/magazine/archive/n2y2016/3581

- Wenwen, Q., Juan, K., Li, Y., Junhui, H. (2016). Young′s Modulus Measurement of Metal Beams Based on Fiber Bragg Grating. Laser & Optoelectronics Progress, 53 (4), 040604. doi: https://doi.org/10.3788/lop53.040604

- Bakanov, V. V., Nureyev, I. I., Kuznetsov, A. A., Lipatnikov, K. A. (2021). Fiber-optic current sensor based on the Bragg grid. Engineering Journal of Don, 6. Available at: http://ivdon.ru/en/magazine/archive/N6y21/7052

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Gulim Kadirbayeva, Katipa Chezhimbayeva, Mukhabbat Khizirova, Waldemar Wójcik

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.