Порівняння хімічного складу та зносу покриттів з алюмінідів заліза та нікелю, отриманих плазмовим напиленням

DOI:

https://doi.org/10.15587/1729-4061.2023.286198Ключові слова:

алюмінід заліза, алюмінід нікелю, плазмове напилення покриттів, сухе тертяАнотація

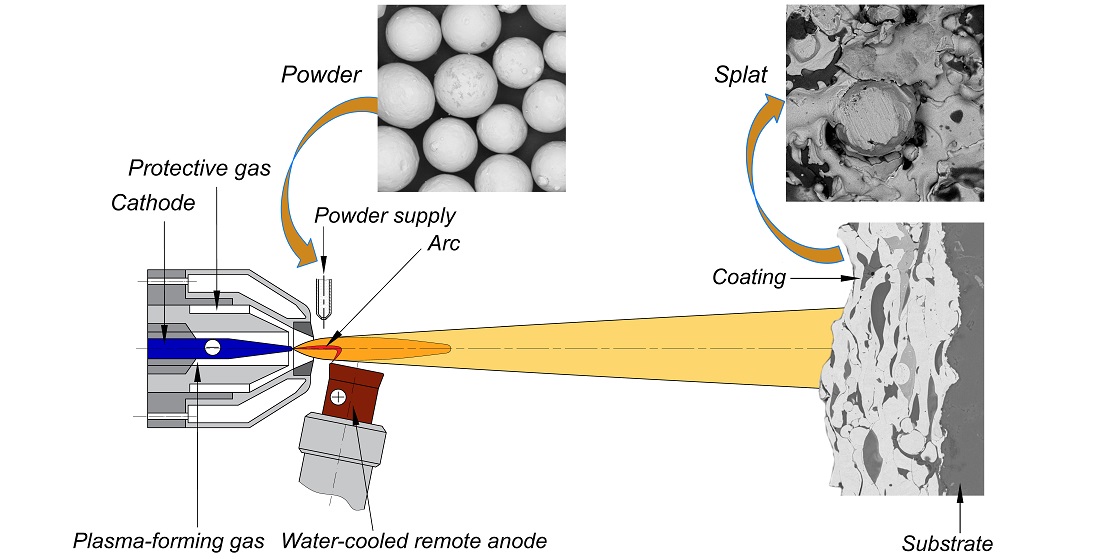

Алюмініди заліза та нікелю завдяки таким властивостям як зносостійкість, корозійна стійкість, жароміцність, контактна та циклічна міцність можуть бути використані як покриття у парах тертя різноманітного призначення. Об'єктом дослідження є процес отримання плазмово-напилених покриттів із порошків на основі алюмінідів заліза та нікелю Проблемою досліджень є визначення та порівняння структури, хімічного складу та зносостійкості покриттів із порошків інтерметалідів алюмініду заліза та алюмініду нікелю, отриманих методом атмосферного плазмового напилення. Для зменшення окиснення порошків під час напилення були створені умови генерації ламінарного плазмового струменя. Такі умови забезпечували спеціально розроблена конструкція електродугового плазмотрона і режимні параметри напилення покриттів. Внаслідок правильного вибору режимів напилення утворювались повністю розплавлені сплети під час зіткнення частинок порошку з поверхню. Отримані покриття мали шарувату мікроструктуру з мікротріщинами та відшаруваннями. Пористість та особливості відшарування покриттів залежать як від режимів, так і технології напилення. Проведені трібологічні випробування покриттів в умовах сухого тертя ковзання метал по металу в парі зі швидкорізальною сталлю Р6М5. Показано, що зношення покриттів з алюмініду нікелю в даних умовах нижче, ніж у покриттів з алюмініду заліза в 2–2,5 рази. Коефіцієнт тертя покриттів з алюмініду заліза незначно нижче ніж у покриттів з алюмініду нікелю. Зношення зразків зі сталі 30ХГСА перевищує зразки з покриттями в 3–4 рази. Відмінність у зношенні покриттів пояснюється більш інтенсивним окисненням алюмініду заліза в процесі тертя. Зроблено висновки стосовно можливості використання досліджених покриттів в різноманітних парах тертя елементів конструкцій, зокрема в автомобільній промисловості

Посилання

- Chen, H., Fan, M., Zhu, W., Norton, A. D. (2020). High temperature oxidation behaviour of combustion flame sprayed CoNiCrAlY coatings. Surface and Coatings Technology, 385, 125431. doi: https://doi.org/10.1016/j.surfcoat.2020.125431

- Rachidi, R., El Kihel, B., Delaunois, F. (2019). Microstructure and mechanical characterization of NiCrBSi alloy and NiCrBSi-WC composite coatings produced by flame spraying. Materials Science and Engineering: B, 241, 13–21. doi: https://doi.org/10.1016/j.mseb.2019.02.002

- Grigoriev, O. N., Shvets, V. A., Podchernyaeva, I. A., Yurechko, D. V., Vedel, D. V., Zubarev, A. A. et al. (2020). Electrochemical Corrosion of Composite Ceramics and Thermal Spray Coatings in the ZrB2–SiC–AlN System. Powder Metallurgy and Metal Ceramics, 59 (7-8), 394–400. doi: https://doi.org/10.1007/s11106-020-00173-2

- Lyashenko, B. A., Veremchuk, V. S., Dolgov, N. A., Ivanov, V. M. (1996). Strength and deformation properties of compositions with plasma-sprayed coatings. Strength of Materials, 28 (6), 452–454. doi: https://doi.org/10.1007/bf02209316

- Zhang, H., Chen, X., Gong, Y., Tian, Y., McDonald, A., Li, H. (2020). In-situ SEM observations of ultrasonic cavitation erosion behavior of HVOF-sprayed coatings. Ultrasonics Sonochemistry, 60, 104760. doi: https://doi.org/10.1016/j.ultsonch.2019.104760

- Raza, A., Ahmad, F., Badri, T. M., Raza, M. R., Malik, K. (2022). An Influence of Oxygen Flow Rate and Spray Distance on the Porosity of HVOF Coating and Its Effects on Corrosion—A Review. Materials, 15 (18), 6329. doi: https://doi.org/10.3390/ma15186329

- Pawlowski, L. (2008). The Science and Engineering of Thermal Spray Coatings. John Wiley & Sons. doi: https://doi.org/10.1002/9780470754085

- Smyrnov, I. V., Chornyi, A. V., Kopylov, V. I. (2020). Effect of Nanodispersed Ingredients on the Properties of Plasma Coatings. Metallofizika I Noveishie Tekhnologii, 42 (6), 797–814. doi: https://doi.org/10.15407/mfint.42.06.0797

- Gérard, B. (2006). Application of thermal spraying in the automobile industry. Surface and Coatings Technology, 201 (5), 2028–2031. doi: https://doi.org/10.1016/j.surfcoat.2006.04.050

- Gudz, G., Zakhara, I., Voitsikhovska, T., Vytvytskyi, V., Ropyak, L. (2022). Temperature Distribution in Parts of the Vehicle Disk Brake. Lecture Notes in Mechanical Engineering, 517–529. doi: https://doi.org/10.1007/978-3-031-16651-8_49

- Aranke, O., Algenaid, W., Awe, S., Joshi, S. (2019). Coatings for Automotive Gray Cast Iron Brake Discs: A Review. Coatings, 9 (9), 552. doi: https://doi.org/10.3390/coatings9090552

- Cinca, N., Lima, C. R. C., Guilemany, J. M. (2013). An overview of intermetallics research and application: Status of thermal spray coatings. Journal of Materials Research and Technology, 2 (1), 75–86. doi: https://doi.org/10.1016/j.jmrt.2013.03.013

- Wang, H., An, F., Bai, X., Yao, H., Zhang, M., Chen, Q. et al. (2023). Improvement of Microstructure and Sliding Wear Property of Cold-Sprayed FeAl Intermetallic Compound Coating by Annealing Treatment. Coatings, 13 (7), 1260. doi: https://doi.org/10.3390/coatings13071260

- Chrostek, T. (2021). Tribological wear of Fe-Al coatings applied by gas detonation spraying. Technical Sciences, 24 (1), 245–256. doi: https://doi.org/10.31648/ts.7129

- Senderowski, C., Bojar, Z., Wołczyński, W Pawłowski, A. (2010). Microstructure characterization of D-gun sprayed Fe–Al intermetallic coatings. Intermetallics, 18 (7), 1405–1409. doi: https://doi.org/10.1016/j.intermet.2010.01.015

- Vijaya Lakshmi, D., Suresh Babu, P., Rama Krishna, L., Vijay, R., Srinivasa Rao, D., Padmanabham, G. (2021). Corrosion and erosion behavior of iron aluminide (FeAl(Cr)) coating deposited by detonation spray technique. Advanced Powder Technology, 32 (7), 2192–2201. doi: https://doi.org/10.1016/j.apt.2021.04.032

- Senapati, P., Sutar, H., Murmu, R., Gupta, S. (2022). Slurry Erosion Behaviour of HVOF-Sprayed NiAl Composite Coating. Lecture Notes in Mechanical Engineering, 623–629. doi: https://doi.org/10.1007/978-981-16-9057-0_68

- Starosta, R. (2009). Properties of Thermal Spraying Ni-Al Alloy Coatings. Advances in Materials Sciences, 9 (1). doi: https://doi.org/10.2478/v10077-009-0004-2

- Hawk, J. A., Alman, D. E. (1997). Abrasive wear of intermetallic-based alloys and composites. Materials Science and Engineering: A, 239-240, 899–906. doi: https://doi.org/10.1016/s0921-5093(97)00681-3

- Меlnik, О. В., Smirnov, I. V., Labunets, V. F., Сhorniy, A. V. (2020). Research of wear resistance of plasma coatings in the conditions of abrasive wear. Problems of Friction and Wear, 3 (88), 126–131. doi: https://doi.org/10.18372/0370-2197.3(88).14928

- Ghosh, G., Korniyenko, K., Velikanova, T., Sidorko, V. (2008). Aluminium – Chromium – Iron. Landolt-Börnstein - Group IV Physical Chemistry, 44–87. doi: https://doi.org/10.1007/978-3-540-69761-9_5

- Thiem, P. G., Chornyi, A., Smirnov, I. V., Krüger, M. (2017). Comparison of microstructure and adhesion strength of plasma, flame and high velocity oxy-fuel sprayed coatings from an iron aluminide powder. Surface and Coatings Technology, 324, 498–508. doi: https://doi.org/10.1016/j.surfcoat.2017.06.016

- Neiser, R. A., Smith, M. F., Dykhuizen, R. C. (1998). Oxidation in Wire HVOF-Sprayed Steel. Journal of Thermal Spray Technology, 7 (4), 537–545. doi: https://doi.org/10.1361/105996398770350765

##submission.downloads##

Опубліковано

Як цитувати

Номер

Розділ

Ліцензія

Авторське право (c) 2023 Igor Smirnov, Andrii Chornyi, Volodymyr Lysak, Nikolay Dolgov, Ihor Sіеliverstov, Kostiantyn Parshenko

Ця робота ліцензується відповідно до Creative Commons Attribution 4.0 International License.

Закріплення та умови передачі авторських прав (ідентифікація авторства) здійснюється у Ліцензійному договорі. Зокрема, автори залишають за собою право на авторство свого рукопису та передають журналу право першої публікації цієї роботи на умовах ліцензії Creative Commons CC BY. При цьому вони мають право укладати самостійно додаткові угоди, що стосуються неексклюзивного поширення роботи у тому вигляді, в якому вона була опублікована цим журналом, але за умови збереження посилання на першу публікацію статті в цьому журналі.

Ліцензійний договір – це документ, в якому автор гарантує, що володіє усіма авторськими правами на твір (рукопис, статтю, тощо).

Автори, підписуючи Ліцензійний договір з ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР», мають усі права на подальше використання свого твору за умови посилання на наше видання, в якому твір опублікований. Відповідно до умов Ліцензійного договору, Видавець ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР» не забирає ваші авторські права та отримує від авторів дозвіл на використання та розповсюдження публікації через світові наукові ресурси (власні електронні ресурси, наукометричні бази даних, репозитарії, бібліотеки тощо).

За відсутності підписаного Ліцензійного договору або за відсутністю вказаних в цьому договорі ідентифікаторів, що дають змогу ідентифікувати особу автора, редакція не має права працювати з рукописом.

Важливо пам’ятати, що існує і інший тип угоди між авторами та видавцями – коли авторські права передаються від авторів до видавця. В такому разі автори втрачають права власності на свій твір та не можуть його використовувати в будь-який спосіб.