Identification of regularities in the behavior of a glass fiber-reinforced polyester composite of the impact test based on ASTM D256 standard

DOI:

https://doi.org/10.15587/1729-4061.2023.286541Keywords:

impact test, shear stresses, total deformation, static structure, IZOD testAbstract

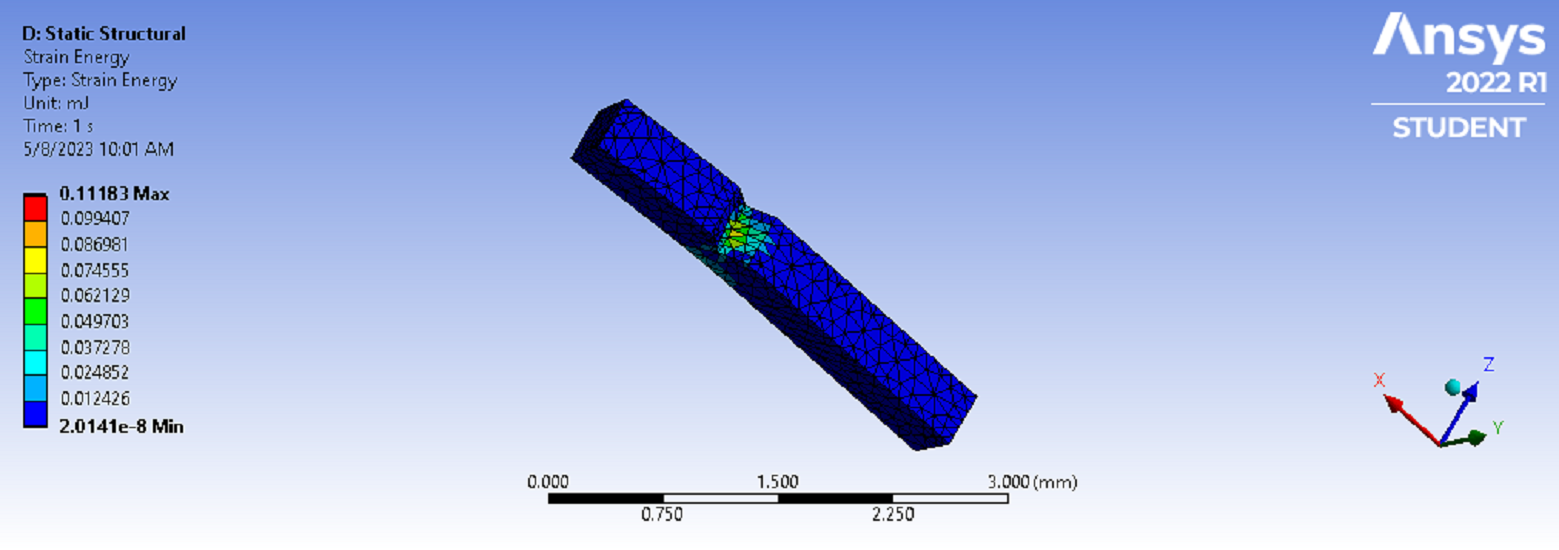

In this research, commotional analysis based on the finite element analysis (FEA) has been performed to investigate IZOD impact test based on the ASTM D256 standard. The ANSYS model primarily employs a composite constructed of glass fiber-reinforced polyester for the boundary conditions. The CEAST 9050 instrument was used to implement the impacting technique in the experimental inquiry. By employing mathematics, we have calculated that the applied force is 9.2 N. A hammer traveling at a speed of 3.5 meters per second is used to strike the samples, and the results are recorded after each blow. The object of this study is the mechanical properties and structural integrity of the composite material composed of glass fibers and polyester when subjected to impact forces. The main hypothesis of the study encompasses the optimism that the glass fiber-reinforced polyester composite, when put through the Izod impact test in accordance with ASTM D256. Convergence between the overall deformation indicator and the numerical result has occurred. Results from the numerical analysis were examined and confirmed, and compared to those from the experiment. The specimens in this study were totally distorted at three different thicknesses (6 mm, 8 mm, and 10 mm). Deformation was found to be greatest for the thinnest value of thickness considered in the study (6 millimeters), as determined by the results of the computer analysis. This was the case even though the thickness value was not the sole criterion. This is the actual state of affairs. The specimen was subjected to a von-Mises stress at three different thicknesses of 6 mm, 8 mm, and 10 mm. The computer investigation revealed that the Von-Mises stress was highest at the thinnest possible thickness of just 6 millimeters. Internal energy, kinetic energy, and touch energy are only few of the various types of energy that have been studied in the context of energy conservation

References

- Santhosh, M. S., Sasikumar, R., Natrayan, L., Kumar, M. S., Elango, V., Vanmathi, M. (2018). Investigation of Mechanical and Electrical Properties of Kevlar/E-Glass and Basalt/E-Glass Reinforced Hybrid Composites. International Journal of Mechanical and Production Engineering Research and Development, 8 (3), 591–598. doi: https://doi.org/10.24247/ijmperdjun201863

- Bardiya, S., Jerald, J., Satheeshkumar, V. (2021). Effect of process parameters on the impact strength of fused filament fabricated (FFF) polylactic acid (PLA) parts. Materials Today: Proceedings, 41, 1103–1106. doi: https://doi.org/10.1016/j.matpr.2020.08.066

- Patterson, A. E., Pereira, T. R., Allison, J. T., Messimer, S. L. (2019). IZOD impact properties of full-density fused deposition modeling polymer materials with respect to raster angle and print orientation. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 235 (10), 1891–1908. doi: https://doi.org/10.1177/0954406219840385

- Dress, G. A., Woldemariam, M. H., Redda, D. T. (2021). Influence of Fiber Orientation on Impact Resistance Behavior of Woven Sisal Fiber Reinforced Polyester Composite. Advances in Materials Science and Engineering, 2021, 1–11. doi: https://doi.org/10.1155/2021/6669600

- Tuazon, B. J., Espino, M. T., Dizon, J. R. C. (2020). Investigation on the Effects of Acetone Vapor-Polishing to Fracture Behavior of ABS Printed Materials at Different Operating Temperature. Materials Science Forum, 1005, 141–149. doi: https://doi.org/10.4028/www.scientific.net/msf.1005.141

- Ansari, A. A., Kamil, M. (2022). Izod impact and hardness properties of 3D printed lightweight CF-reinforced PLA composites using design of experiment. International Journal of Lightweight Materials and Manufacture, 5 (3), 369–383. doi: https://doi.org/10.1016/j.ijlmm.2022.04.006

- Souza, A. T., Neuba, L. de M., Junio, R. F. P., Carvalho, M. T., Candido, V. S., Figueiredo, A. B.-H. da S. et al. (2022). Ballistic Properties and Izod Impact Resistance of Novel Epoxy Composites Reinforced with Caranan Fiber (Mauritiella armata). Polymers, 14 (16), 3348. doi: https://doi.org/10.3390/polym14163348

- Seprianto, D., Sugiantoro, R., Siproni, Yahya, Erwin, M. (2020). The Effect of Rectangular Parallel Key Manufacturing Process Parameters Made with Stereolithography DLP 3D Printer Technology Against Impact Strength. Journal of Physics: Conference Series, 1500 (1), 012028. doi: https://doi.org/10.1088/1742-6596/1500/1/012028

- Salman, S., Sharaf, H. K., Hussein, A. F., Khalaf, N. J., Abbas, M. K., Aned, A. M. et al. (2022). Optimization of raw material properties of natural starch by food glue based on dry heat method. Food Science and Technology, 42. doi: https://doi.org/10.1590/fst.78121

- Almagsoosi, L., Abadi, M. T. E., Hasan, H. F., Sharaf, H. K. (2022). Effect of the Volatility of the Crypto Currency and Its Effect on the Market Returns. Industrial Engineering & Management Systems, 21 (2), 238–243. doi: https://doi.org/10.7232/iems.2022.21.2.238

- Ashham, M., Sharaf, H. K., Salman, K., Salman, S. (2017). Simulation of heat transfer in a heat exchanger tube with inclined vortex rings inserts. International Journal of Applied Engineering, 12 (20), 9605–9613. Available at: https://www.ripublication.com/ijaer17/ijaerv12n20_48.pdf

- Raheemah, S. H., Fadheel, K. I., Hassan, Q. H., Aned, A. M., Turki Al-Taie, A. A., Sharaf, H. K. (2021). Numerical Analysis of the Crack Inspections Using Hybrid Approach for the Application the Circular Cantilever Rods. Pertanika Journal of Science and Technology, 29 (2). doi: https://doi.org/10.47836/pjst.29.2.22

- Subhi, K. A., Hussein, E. K., Al-Hamadani, H. R. D., Sharaf, H. K. (2022). Investigation of the mechanical performance of the composite prosthetic keel based on the static load: a computational analysis. Eastern-European Journal of Enterprise Technologies, 3 (7 (117)), 22–30. doi: https://doi.org/10.15587/1729-4061.2022.256943

- Sharaf, H. K., Alyousif, S., Khalaf, N. J., Hussein, A. F., Abbas, M. K. (2022). Development of bracket for cross arm structure in transmission tower: Experimental and numerical analysis. New Materials, Compounds and Applications, 6 (3), 257–275. Available at: http://jomardpublishing.com/UploadFiles/Files/journals/NMCA/V6N3/SharafHS.pdf

- Reuben, R., Joshi, P., Manickam, R. (2020). Effect of Copper Nano Powder on Kevlar Fiber Reinforced Epoxy Resin Composites. IOP Conference Series: Materials Science and Engineering, 810 (1), 012053. doi: https://doi.org/10.1088/1757-899x/810/1/012053

- Tran, N.-T., Pham, N. T.-H. (2021). Investigation of the Effect of Polycarbonate Rate on Mechanical Properties of Polybutylene Terephthalate/Polycarbonate Blends. International Journal of Polymer Science, 2021, 1–7. doi: https://doi.org/10.1155/2021/7635048

- Tanveer, Md. Q., Haleem, A., Suhaib, M. (2019). Effect of variable infill density on mechanical behaviour of 3-D printed PLA specimen: an experimental investigation. SN Applied Sciences, 1 (12). doi: https://doi.org/10.1007/s42452-019-1744-1

- Raut, N. P., Kolekar, A. B. (2023). Experimental analysis of 3D printed specimens with different printing parameters for Izod impact strength. Materials Today: Proceedings, 80, 156–162. doi: https://doi.org/10.1016/j.matpr.2022.11.029

- Akdoğan, E. (2020). The effects of high density polyethylene addition to low density polyethylene polymer on mechanical, impact and physical properties. European Journal of Technic, 10 (1), 25–37. doi: https://doi.org/10.36222/ejt.646693

- Nweze Nwogu, C., Nwaiwu, U., Uchechukwu Udo, V., James Nwosu, O., Ezenwa Hart, C. (2022). Effect of date seed granules on the mechanical properties of Glass fibre reinforced epoxy composite. Cleaner Materials, 6, 100160. doi: https://doi.org/10.1016/j.clema.2022.100160

- Thandavamoorthy, R., Palanivel, A. (2019). Testing and Evaluation of Tensile and Impact Strength of Neem/Banyan Fiber-Reinforced Hybrid Composite. Journal of Testing and Evaluation, 48 (1), 20180640. doi: https://doi.org/10.1520/jte20180640

- Mishra, P. K., Senthil, P., Adarsh, S., Anoop, M. S. (2021). An investigation to study the combined effect of different infill pattern and infill density on the impact strength of 3D printed polylactic acid parts. Composites Communications, 24, 100605. doi: https://doi.org/10.1016/j.coco.2020.100605

- Patterson, A. E., Hasanov, S., Vajipeyajula, B. (2022). Influence of Matrix Material on Impact Properties of Chopped Carbon Fiber-Thermoplastic Composites Made Using FDM/FFF. 2022 International Additive Manufacturing Conference. doi: https://doi.org/10.1115/iam2022-88941

- Rusiyanto, Irfan, M., Widodo, R. D., Sunyoto, Fitriyana, D. F. (2023). Effect of drying time on compressive strength, impact strength and macro structure of crucible materials made from evaporation boats waste, graphite and kaolin. AIP Conference Proceedings. doi: https://doi.org/10.1063/5.0124101

- Kholil, A., Syaefuddin, E. A., Supardi, F., Wulandari, D. A. (2022). The Effect of Layer Thickness on Impact Strength Characteristics of ABS and PLA Materials. Journal of Physics: Conference Series, 2377 (1), 012001. doi: https://doi.org/10.1088/1742-6596/2377/1/012001

- Velasco, D. C. R., Linhares, J. A. T., Simonassi, N. T., Vieira, C. M. F., Azevedo, A. R. G., Marvila, M. T., Monteiro, S. N. (2023). Influence of the Incorporation of Particulates from the Pineapple Crown on the Impact Strength of Epoxy Systems. TMS 2023 152nd Annual Meeting & Exhibition Supplemental Proceedings, 1252–1257. doi: https://doi.org/10.1007/978-3-031-22524-6_120

- Kamaal, M., Anas, M., Rastogi, H., Bhardwaj, N., Rahaman, A. (2020). Effect of FDM process parameters on mechanical properties of 3D-printed carbon fibre–PLA composite. Progress in Additive Manufacturing, 6 (1), 63–69. doi: https://doi.org/10.1007/s40964-020-00145-3

- Madu, K., Okoronkwo, G. O., Nwankwo, E. I. (2019). Effects of fiber volume fraction and curing time on impact – Hardness strength properties of areca fibers reinforced polyester thermoset composites. An International Open Free Access, Peer Reviewed Research Journal, 1 (2).

- Kumar, R., Rani, M., Zafar, S. (2021). Influence of stacking sequence on impact strength/hardness of CF/GF hybrid composites fabricated by VARIMC technique. Materials Today: Proceedings, 45, 4666–4670. doi: https://doi.org/10.1016/j.matpr.2021.01.114

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Imad O. Bachi Al-Fahad, Azzam D. Hassan, Batool Mardan Faisal, Hussein kadhim Sharaf

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.