Виявлення особливостей структурно-фазових перетворень при переробці оксидних відходів від виробництва швидкоріжучої сталі

DOI:

https://doi.org/10.15587/1729-4061.2023.288506Ключові слова:

вуглецевотермічне відновлення, окалина швидкоріжучих сталей, оксидні техногенні відходи, структурно-фазові перетворенняАнотація

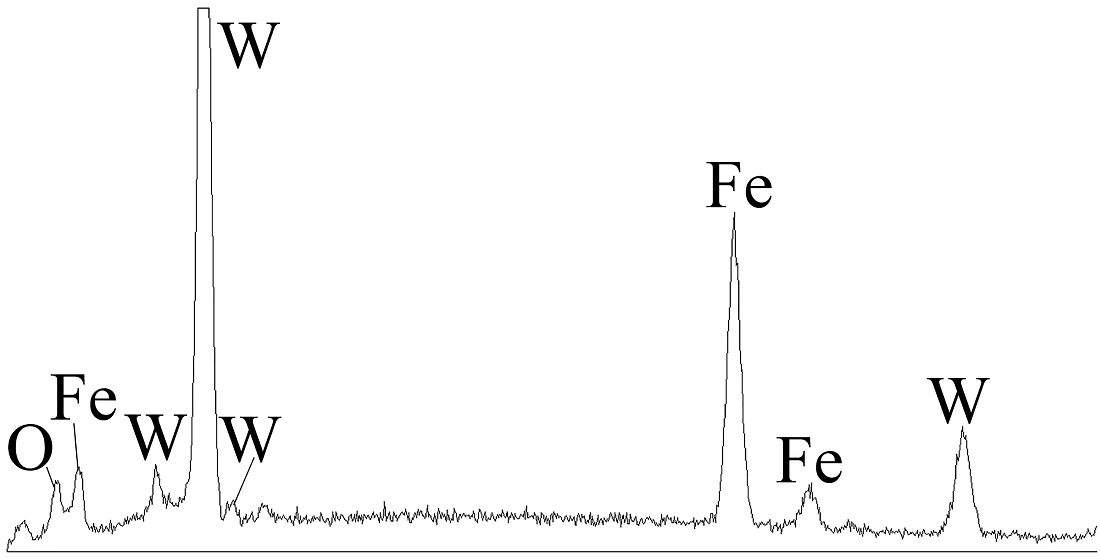

Досліджено особливості фазових та структурних перетворень при вуглецевотермічному відновленні окалини швидкоріжучої сталі з отриманням добавки для легування. Це потрібно для визначення технологічних показників, що дозволяють зменшити втрати високовартісних елементів під час отримання та використання легуючої добавки. Поетапна зміна ступеня відновлення окалини з 32 % до 69 % та 77 % обумовила посилення прояву твердого розчину легуючих елементів та вуглецю в гратці α-Fe відносно до FeWO4 та Fe3O4. Разом з цим мали прояв Fe3C, FeW3C, WC, VC, V2C та Cr3C2. При цьому спостерігалося утворення часток багатогранної та округлої форми різного хімічного складу та формування губчастої мікроструктури. Визначено, що найбільш прийнятний ступінь відновлення складає 77 %. При цьому ступінь відновлення 69 % також є достатнім, так як завдяки залишковому вуглецю у вигляді карбідів забезпечується підвищена відновна здатність з довідновленням оксидної складової в рідкому металі при легуванні. Губчаста мікроструктура забезпечує відносно швидке розчинення в порівнянні із стандартними феросплавами, що обумовлює зниження загального часу плавки при зменшенні витрачених ресурсів. В отриманій легуючій добавці не було виявлено фаз і з’єднань, що характеризуються підвищеною схильністю до сублімації. Тобто немає потреби забезпечення додаткових умов, що перешкоджають втраті високовартісних елементів при випаровуванні з газовою фазою, що обумовлює зростання ступеня вилучення легуючих елементів. Показники отриманої легуючої добавки дають можливість виплавки легованої сталі в електродуговій печі відповідно марок, склад яких не має суворих обмежень за вуглецем, при заміні частини стандартних феросплавів

Посилання

- Petryshchev, A., Milko, D., Borysov, V., Tsymbal, B., Hevko, I., Borysova, S., Semenchuk, A. (2019). Studying the physicalchemical transformations at resourcesaving reduction melting of chrome–nickelcontaining metallurgical waste. Eastern-European Journal of Enterprise Technologies, 2 (12 (98)), 59–64. doi: https://doi.org/10.15587/1729-4061.2019.160755

- Henckens, M. L. C. M., van Ierland, E. C., Driessen, P. P. J., Worrell, E. (2016). Mineral resources: Geological scarcity, market price trends, and future generations. Resources Policy, 49, 102–111. doi: https://doi.org/10.1016/j.resourpol.2016.04.012

- Sekiguchi, N. (2017). Trade specialisation patterns in major steelmaking economies: the role of advanced economies and the implications for rapid growth in emerging market and developing economies in the global steel market. Mineral Economics, 30 (3), 207–227. doi: https://doi.org/10.1007/s13563-017-0110-2

- Mechachti, S, Benchiheub, O., Serrai, S., Shalabi, M. (2013). Preparation of iron Powders by Reduction of Rolling Mill Scale. International Journal of Scientific & Engineering Research, 4 (5), 1467–1472. Available at: https://www.researchgate.net/publication/269463295_Preparation_of_iron_Powders_by_Reduction_of_Rolling_Mill_Scale_International_Journal_of_Scientific_Engineering_Research_Volume_4_Issue_5_May-20131457-1472

- Grigor’ev, S. M., Petrishchev, A. S. (2012). Assessing the phase and structural features of the scale on P6M5Φ3 and P12M3K5Φ2 steel. Steel in Translation, 42 (3), 272–275. doi: https://doi.org/10.3103/s0967091212030059

- Hryhoriev, S., Petryshchev, A., Shyshkanova, G., Zaytseva, T., Frydman, O., Krupey, K. et al. (2018). A study of environmentally friendly recycling of technogenic chromium and nickel containing waste by the method of solid phase extraction. Eastern-European Journal of Enterprise Technologies, 1 (10 (91)), 44–49. doi: https://doi.org/10.15587/1729-4061.2018.121615

- Hryhoriev, S., Petryshchev, A., Belokon’, K., Krupey, K., Yamshinskij, M., Fedorov, G. et al. (2018). Determining the physical-chemical characteristics of the carbon-thermal reduction of scale of tungsten high-speed steels. Eastern-European Journal of Enterprise Technologies, 2 (6 (92)), 10–15. doi: https://doi.org/10.15587/1729-4061.2018.125988

- Zhu, H., Li, Z., Yang, H., Luo, L. (2013). Carbothermic Reduction of MoO3 for Direct Alloying Process. Journal of Iron and Steel Research International, 20 (10), 51–56. doi: https://doi.org/10.1016/s1006-706x(13)60176-4

- Grigor’ev, S. M., Petrishchev, A. S. (2015). Refining metallized molybdenum concentrate by means of a low-temperature plasma-forming mixture. Steel in Translation, 45 (12), 954–958. doi: https://doi.org/10.3103/s0967091215120049

- Baghdasaryan, A. M., Niazyan, O. M., Khachatryan, H. L., Kharatyan, S. L. (2014). DTA/TG study of tungsten oxide and ammonium tungstate reduction by (Mg+C) combined reducers at non-isothermal conditions. International Journal of Refractory Metals and Hard Materials, 43, 216–221. doi: https://doi.org/10.1016/j.ijrmhm.2013.12.003

- Islam, M., Martinez-Duarte, R. (2017). A sustainable approach for tungsten carbide synthesis using renewable biopolymers. Ceramics International, 43 (13), 10546–10553. doi: https://doi.org/10.1016/j.ceramint.2017.05.118

- Chen, S. Y., Chu, M. S. (2014). A new process for the recovery of iron, vanadium, and titanium from vanadium titanomagnetite. The Journal of the Southern African Institute of Mining and Metallurgy, 114, 481–487. Available at: https://www.saimm.co.za/Journal/v114n06p481.pdf

- Zhao, L., Wang, L., Chen, D., Zhao, H., Liu, Y., Qi, T. (2015). Behaviors of vanadium and chromium in coal-based direct reduction of high-chromium vanadium-bearing titanomagnetite concentrates followed by magnetic separation. Transactions of Nonferrous Metals Society of China, 25 (4), 1325–1333. doi: https://doi.org/10.1016/s1003-6326(15)63731-1

##submission.downloads##

Опубліковано

Як цитувати

Номер

Розділ

Ліцензія

Авторське право (c) 2023 Vadym Volokh, Anatolii Poliakov, Victor Rebenko, Andrey Andreev, Mykhail Yamshinskij, Ivan Lukianenko, Viacheslav Kurlov, Yevhen Chaplyhin, Nataliya Vlasenko, Dmytro Ivanchenko

Ця робота ліцензується відповідно до Creative Commons Attribution 4.0 International License.

Закріплення та умови передачі авторських прав (ідентифікація авторства) здійснюється у Ліцензійному договорі. Зокрема, автори залишають за собою право на авторство свого рукопису та передають журналу право першої публікації цієї роботи на умовах ліцензії Creative Commons CC BY. При цьому вони мають право укладати самостійно додаткові угоди, що стосуються неексклюзивного поширення роботи у тому вигляді, в якому вона була опублікована цим журналом, але за умови збереження посилання на першу публікацію статті в цьому журналі.

Ліцензійний договір – це документ, в якому автор гарантує, що володіє усіма авторськими правами на твір (рукопис, статтю, тощо).

Автори, підписуючи Ліцензійний договір з ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР», мають усі права на подальше використання свого твору за умови посилання на наше видання, в якому твір опублікований. Відповідно до умов Ліцензійного договору, Видавець ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР» не забирає ваші авторські права та отримує від авторів дозвіл на використання та розповсюдження публікації через світові наукові ресурси (власні електронні ресурси, наукометричні бази даних, репозитарії, бібліотеки тощо).

За відсутності підписаного Ліцензійного договору або за відсутністю вказаних в цьому договорі ідентифікаторів, що дають змогу ідентифікувати особу автора, редакція не має права працювати з рукописом.

Важливо пам’ятати, що існує і інший тип угоди між авторами та видавцями – коли авторські права передаються від авторів до видавця. В такому разі автори втрачають права власності на свій твір та не можуть його використовувати в будь-який спосіб.