Визначення характеру руху сипких матеріалів у шнекових та трубчасто-гребеневих живильниках

DOI:

https://doi.org/10.15587/1729-4061.2023.291680Ключові слова:

сипкий матеріал, трубчасто-гребеневий живильник, метод дискретних елементів, МДЕ, пульсації сипкого матеріалуАнотація

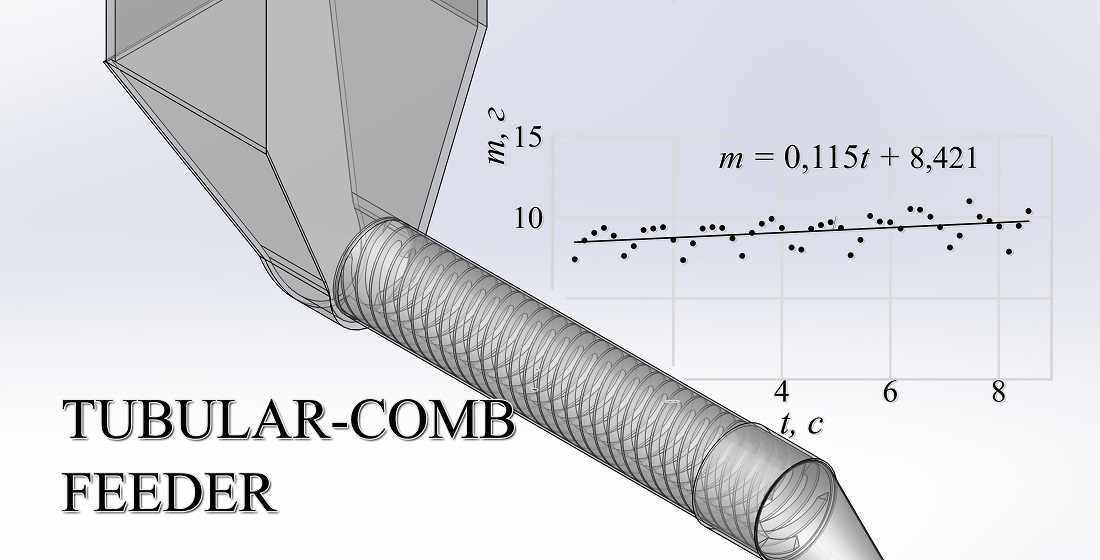

Об’єктом дослідження є взаємозв’язок між конструктивними і технологічними параметрами живильників сипких матеріалів та характеристиками потоків частинок на їх виході, а саме: продуктивністю та величиною пульсацій. Проаналізовано існуючі конструкції обладнання цього типу, визначено найбільш поширені методи моделювання їх роботи. Авторами запропонована конструкція трубчасто-гребеневого живильника, робота якої порівнюється з відомим шнековим живильником. На основі методу дискретних елементів розроблено комп’ютерні моделі обох конструкцій. Моделювання проведено в програмному середовищі EDEM 2017. Встановлено, що отримані моделі враховують дискретну природу руху сипких матеріалів, дозволяють проводити дослідження з урахуванням фізико-механічних властивостей окремих частинок.

Створено дослідний стенд для експериментальної перевірки режимів роботи трубчасто-гребеневого живильника. Визначено продуктивності живильника цього типу для двох швидкостей обертання труби (6 і 10 рад/с). Також визначено величину пульсацій потоку матеріалу у вихідному патрубку. Підтверджено відповідність результатів розрахунків за комп’ютерною моделлю реальному процесу. Зазначені дослідження проводились для усталених режимів роботи.

Встановлено, що за рівних габаритних розмірів та швидкостей обертання робочих органів, продуктивність шнекового живильника у 5…5,2 разів більша ніж у трубчасто-гребеневого. Але останній забезпечує у 7,3…16,4 разів меншу величину пульсацій потоку сипкого матеріалу. Це дозволяє знизити неоднорідність сумішей, особливо у випадку використання таких живильників у складі змішувальних комплексів безперервної дії.

Отримані результати дозволяють аналізувати роботу живильників сипких матеріалів та зменшити час їх проєктування

Посилання

- Burmistenkov, O. P. et al. (2007). Vyrobnytstvo lytykh detalei ta vyrobiv z polimernykh materialiv u vzuttieviy ta shkirhalantereinii promyslovosti. Khmelnytskyi: [b.v.], 255.

- Beloshenko, V., Voznyak, Y., Voznyak, A., Savchenko, B. (2017). New approach to production of fiber reinforced polymer hybrid composites. Composites Part B: Engineering, 112, 22–30. doi: https://doi.org/10.1016/j.compositesb.2016.12.030

- Kulik, T., Synyuk, O., Zlotenko, B. (2017). Modeling a process of filling the mold during injection molding of polymeric parts. Eastern-European Journal of Enterprise Technologies, 5 (1 (89)), 70–77. doi: https://doi.org/10.15587/1729-4061.2017.110820

- Statsenko, V., Burmistenkov, O., Bila, T., Statsenko, D. (2019). Determining the motion character of loose materials in the system of continuous action «hopper – reciprocating plate feeder». Eastern-European Journal of Enterprise Technologies, 2 (1 (98)), 21–28. doi: https://doi.org/10.15587/1729-4061.2019.163545

- Zheng, Q. J., Xu, M. H., Chu, K. W., Pan, R. H., Yu, A. B. (2017). A coupled FEM/DEM model for pipe conveyor systems: Analysis of the contact forces on belt. Powder Technology, 314, 480–489. doi: https://doi.org/10.1016/j.powtec.2016.09.070

- Toson, P., Khinast, J. G. (2023). A DEM model to evaluate refill strategies of a twin-screw feeder. International Journal of Pharmaceutics, 641, 122915. doi: https://doi.org/10.1016/j.ijpharm.2023.122915

- Santos, L. S., Macêdo, E. N., Ribeiro Filho, P. R. C. F., Cunha, A. P. A., Cheung, N. (2023). Belt Rotation in Pipe Conveyors: Failure Mode Analysis and Overlap Stability Assessment. Sustainability, 15 (14), 11312. doi: https://doi.org/10.3390/su151411312

- Karwat, B., Machnik, R., Niedźwiedzki, J., Nogaj, M., Rubacha, P., Stańczyk, E. (2019). Calibration of bulk material model in Discrete Element Method on example of perlite D18-DN. Eksploatacja i Niezawodność – Maintenance and Reliability, 21 (2), 351–357. doi: https://doi.org/10.17531/ein.2019.2.20

- Cleary, P. W. (2007). DEM modelling of particulate flow in a screw feeder Model description. Progress in Computational Fluid Dynamics, An International Journal, 7 (2/3/4), 128. doi: https://doi.org/10.1504/pcfd.2007.013005

- Hou, Q. F., Dong, K. J., Yu, A. B. (2014). DEM study of the flow of cohesive particles in a screw feeder. Powder Technology, 256, 529–539. doi: https://doi.org/10.1016/j.powtec.2014.01.062

- Kretz, D., Callau-Monje, S., Hitschler, M., Hien, A., Raedle, M., Hesser, J. (2016). Discrete element method (DEM) simulation and validation of a screw feeder system. Powder Technology, 287, 131–138. doi: https://doi.org/10.1016/j.powtec.2015.09.038

- Owen, P. J., Cleary, P. W. (2009). Prediction of screw conveyor performance using the Discrete Element Method (DEM). Powder Technology, 193 (3), 274–288. doi: https://doi.org/10.1016/j.powtec.2009.03.012

- Shi, Q., Sakai, M. (2022). Recent progress on the discrete element method simulations for powder transport systems: A review. Advanced Powder Technology, 33 (8), 103664. doi: https://doi.org/10.1016/j.apt.2022.103664

- Statsenko, V., Burmistenkov, O., Bila, T., Demishonkova, S. (2021). Determining the loose medium movement parameters in a centrifugal continuous mixer using a discrete element method. Eastern-European Journal of Enterprise Technologies, 3 (7 (111)), 59–67. doi: https://doi.org/10.15587/1729-4061.2021.232636

- Statsenko, V., Burmistenkov, O., Bila, T., Statsenko, D. (2022). Determining the relationship between the simulation duration by the discrete element method and the computer system technical characteristics. Eastern-European Journal of Enterprise Technologies, 6 (4 (120)), 32–39. doi: https://doi.org/10.15587/1729-4061.2022.267033

- Discrete Element Modeling - DEM Software | Altair EDEM. Available at: https://altair.com/edem

- Mindlin, R. D., Deresiewicz, H. (1953). Elastic Spheres in Contact Under Varying Oblique Forces. Journal of Applied Mechanics, 20 (3), 327–344. doi: https://doi.org/10.1115/1.4010702

- Python programming language. Available at: https://www.python.org/

- NumPy. The fundamental package for scientific computing with Python. Available at: https://numpy.org/

- Project Jupyter. Available at: https://jupyter.org/

- Screw feeder – 4 models from D10 to D13. Available at: https://www.palamaticprocess.com/bulk-handling-equipment/screw-feeder

- Screw Feeders. Available at: https://www.screwconveyorbega.com/volumetric-screw-conveyor

- Bunker-zhyvylnyk dlia ekstrudera, hranuliatora. Available at: https://tehnomashstroy.com.ua/ua/p43633546-bunker-pitatel-dlya.html

##submission.downloads##

Опубліковано

Як цитувати

Номер

Розділ

Ліцензія

Авторське право (c) 2023 Volodymyr Nychehlod, Oleksandr Burmistenkov, Volodymyr Statsenko, Tetiana Bila, Dmytro Statsenko

Ця робота ліцензується відповідно до Creative Commons Attribution 4.0 International License.

Закріплення та умови передачі авторських прав (ідентифікація авторства) здійснюється у Ліцензійному договорі. Зокрема, автори залишають за собою право на авторство свого рукопису та передають журналу право першої публікації цієї роботи на умовах ліцензії Creative Commons CC BY. При цьому вони мають право укладати самостійно додаткові угоди, що стосуються неексклюзивного поширення роботи у тому вигляді, в якому вона була опублікована цим журналом, але за умови збереження посилання на першу публікацію статті в цьому журналі.

Ліцензійний договір – це документ, в якому автор гарантує, що володіє усіма авторськими правами на твір (рукопис, статтю, тощо).

Автори, підписуючи Ліцензійний договір з ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР», мають усі права на подальше використання свого твору за умови посилання на наше видання, в якому твір опублікований. Відповідно до умов Ліцензійного договору, Видавець ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР» не забирає ваші авторські права та отримує від авторів дозвіл на використання та розповсюдження публікації через світові наукові ресурси (власні електронні ресурси, наукометричні бази даних, репозитарії, бібліотеки тощо).

За відсутності підписаного Ліцензійного договору або за відсутністю вказаних в цьому договорі ідентифікаторів, що дають змогу ідентифікувати особу автора, редакція не має права працювати з рукописом.

Важливо пам’ятати, що існує і інший тип угоди між авторами та видавцями – коли авторські права передаються від авторів до видавця. В такому разі автори втрачають права власності на свій твір та не можуть його використовувати в будь-який спосіб.