Determining the influence of an artificial defect on the mechanical properties of a flexible pipeline material during a rupture test

DOI:

https://doi.org/10.15587/1729-4061.2023.291877Keywords:

pressure fire hose, flexible pipeline, normal elasticity, longitudinal stiffness of the material, artificial defectAbstract

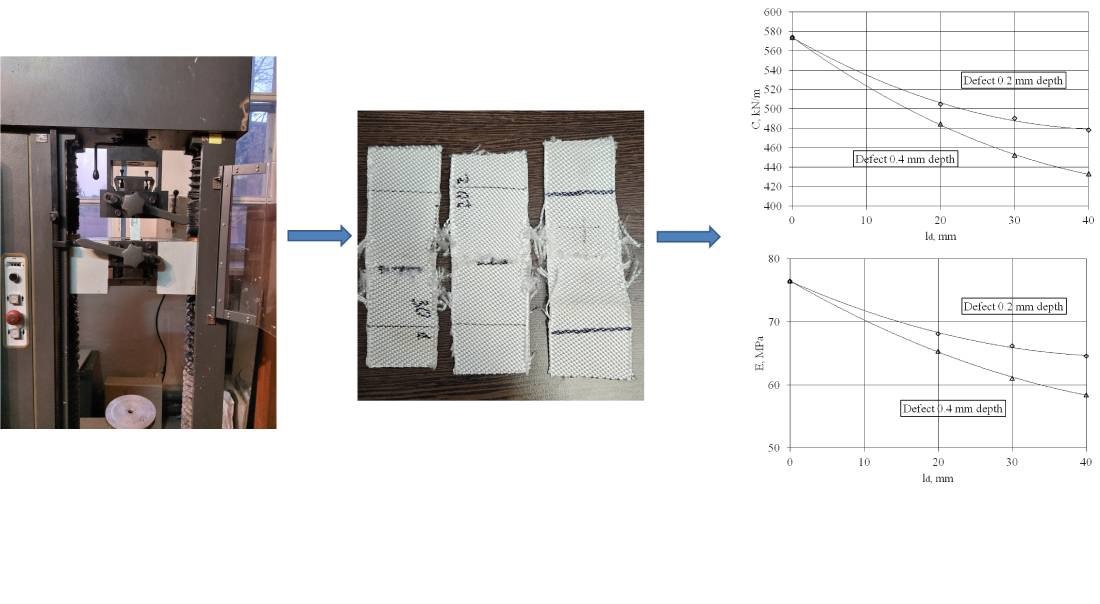

The object of research is the phenomenon of influence of hidden defects on the mechanical properties of the material of flexible pipelines. T-type pressure fire hoses with an inner diameter of 77 mm were used as test samples of flexible pipelines. During the operation of pressurized fire hydrants and their laying on vertical surfaces, they are subjected to significant bursting pressures in their longitudinal direction. That is, such operating modes of the sleeve may occur during its operation. The research was carried out on the FP 100/1 bursting machine, in which the test samples were fixed.

The dependence of the stiffness and normal elasticity of the material of the flexible pipeline on the depth and length of the artificial defect when testing it for breaking has been established. With an artificial defect depth of 0.2 mm and its length from 0 to 40 mm, the stiffness of the flexible pipeline material decreases from 573.812 kN/m to 478.276 kN/m. With the indicated values of the defect, the normal elasticity ranged from 86.46 MPa to 64.567 MPa. When the depth of the defect increases by 0.4 mm, the stiffness of the sleeve material decreases to 432.902 kN/m, and the normal elasticity decreases to 58.442 MPa.

The obtained results are explained by the fact that when the thickness of the threads of the base of the power frame is reduced by 33 %, the longitudinal stiffness and normal elasticity of the material of the flexible pipeline are reduced by 25 % and 26 %, respectively.

The results of these studies are needed in practice because they can make it possible to develop new or improve existing methods of detecting hidden defects in the material from which flexible pipelines are made

References

- Tiutiunyk, V. V., Ivanets, H. V., Tolkunov, I. A., Stetsyuk, E. I. (2018). System approach for readiness assessment units of civil defense to actions at emergency situations. Scientific Bulletin of National Mining University, 1, 99–105. doi: https://doi.org/10.29202/nvngu/2018-1/7

- Arunachala, P. K., Rastak, R., Linder, C. (2021). Energy based fracture initiation criterion for strain-crystallizing rubber-like materials with pre-existing cracks. Journal of the Mechanics and Physics of Solids, 157, 104617. doi: https://doi.org/10.1016/j.jmps.2021.104617

- Tonatto, M. L. P., Forte, M. M. C., Tita, V., Amico, S. C. (2016). Progressive damage modeling of spiral and ring composite structures for offloading hoses. Materials & Design, 108, 374–382. doi: https://doi.org/10.1016/j.matdes.2016.06.124

- Wei, D., An, C., Wu, C., Duan, M., Estefen, S. F. (2022). Torsional structural behavior of composite rubber hose for offshore applications. Applied Ocean Research, 128, 103333. doi: https://doi.org/10.1016/j.apor.2022.103333

- Sun, Z., Huang, W., Lu, H., Bu, Y., Yin, Y., Wang, S., Fan, Y. (2023). Mechanical Characteristics of Fiber-Reinforced Flexible Pipe Subjected to Axial Tensile Load. Journal of Marine Science and Engineering, 11 (3), 586. doi: https://doi.org/10.3390/jmse11030586

- Zhu, X., Lei, Q., Meng, Y., Cui, X. (2021). Analysis of tensile response of flexible pipe with ovalization under hydrostatic pressure. Applied Ocean Research, 108, 102451. doi: https://doi.org/10.1016/j.apor.2020.102451

- de Sousa, J. R. M., Magluta, C., Roitman, N., Campello, G. C. (2018). On the extensional-torsional response of a flexible pipe with damaged tensile armor wires. Ocean Engineering, 161, 350–383. doi: https://doi.org/10.1016/j.oceaneng.2018.04.091

- Yim, K.-H., Jang, B.-S. (2016). A Comparative Study for the Prediction of Ultimate Tensile Strength in Flexible Pipes. Paper presented at the Offshore Technology Conference Asia. doi: https://doi.org/10.4043/26529-ms

- Fang, P., Xu, Y., Gao, Y., Ali, L., Bai, Y. (2022). Mechanical responses of a fiberglass flexible pipe subject to tension & internal pressure. Thin-Walled Structures, 181, 110107. doi: https://doi.org/10.1016/j.tws.2022.110107

- Nazarenko, S., Kovalenko, R., Pobidash, A., Kalynovskiy, A. (2023). Experimental Study of the Sleeve Material Mechanical Properties during the Sample Tensile Test. Key Engineering Materials, 952, 111–118. doi: https://doi.org/10.4028/p-qa0fox

- Larin, O., Morozov, O., Nazarenko, S., Chernobay, G., Kalynovskyi, A., Kovalenko, R. et al. (2019). Determining mechanical properties of a pressure fire hose the type of «T». Eastern-European Journal of Enterprise Technologies, 6 (7 (102)), 63–70. doi: https://doi.org/10.15587/1729-4061.2019.184645

- Nazarenko, S., Kovalenko, R., Asotskyi, V., Chernobay, G., Kalynovskyi, A., Tsebriuk, I. et al. (2020). Determining mechanical properties at the shear of the material of "T" type pressure fire hose based on torsion tests. Eastern-European Journal of Enterprise Technologies, 5 (7 (107), 45–55. doi: https://doi.org/10.15587/1729-4061.2020.212269

- Nazarenko, S., Kovalenko, R., Gavryliuk, A., Vinogradov, S., Kryvoshei, B., Pavlenko, S. et al. (2021). Determining the dissipative properties of a flexible pipeline’s material at stretching in the transverse direction taking its structural elements into consideration. Eastern-European Journal of Enterprise Technologies, 2 (1 (110)), 12–20. doi: https://doi.org/10.15587/1729-4061.2021.227039

- Nazarenko, S., Kushnareva, G., Maslich, N., Knaub, L., Naumenko, N., Kovalenko, R. et al. (2021). Establishment of the dependence of the strength indicator of the composite material of pressure hoses on the character of single damages. Eastern-European Journal of Enterprise Technologies, 6 (1 (114)), 21–27. doi: https://doi.org/10.15587/1729-4061.2021.248972

- Nazarenko, S., Kovalenko, R., Kolienov, O., Saveliev, D., Miachyn, V., Demianyshyn, V. (2022). Influence of the artificial defect on the flexible pipeline twist angle. Archives of Materials Science and Engineering, 114 (2), 58–68. doi: https://doi.org/10.5604/01.3001.0016.0026

- Cho, J. R. (2017). Anisotropic Large Deformation and Fatigue Damage of Rubber-fabric Braid Layered Composite Hose. Procedia Engineering, 173, 1169–1176. doi: https://doi.org/10.1016/j.proeng.2016.12.097

- Fedorko, G., Molnar, V., Dovica, M., Toth, T., Fabianova, J. (2015). Failure analysis of irreversible changes in the construction of the damaged rubber hoses. Engineering Failure Analysis, 58, 31–43. doi: https://doi.org/10.1016/j.engfailanal.2015.08.042

- Nishkala, K., Royan, B. T., Aishwarya, H. M., Sanjika, D. R. V., Kurup, D. G. (2018). Detection of Ruptures in Pipeline Coatings Using Split Ring Resonator Sensor. 2018 International Conference on Advances in Computing, Communications and Informatics (ICACCI). doi: https://doi.org/10.1109/icacci.2018.8554620

- Boaz, L., Kaijage, S., Sinde, R. (2014). An overview of pipeline leak detection and location systems. Proceedings of the 2nd Pan African International Conference on Science, Computing and Telecommunications (PACT 2014). doi: https://doi.org/10.1109/scat.2014.7055147

- Eckold, G., White, R. (2017). Real-Time Asset Optimisation - Integrity Management of Flexible Pipe Systems: Meeting the Challenge. Paper presented at the OTC Brasil. doi: https://doi.org/10.4043/28078-ms

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Sergii Nazarenko, Roman Kovalenko, Andrii Kalynovskyi, Andrii Pobidash, Volodymyr Nazarenko, Yevheniia Kravchenko, Olga Shoman, Volodymyr Danylenko, Olena Sydorenko

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.