Optimization of lawele granular asphalt (LGA) performance in cold paving hot mix asbuton (CPHMA) with candlenut oil modifier

DOI:

https://doi.org/10.15587/1729-4061.2023.292080Keywords:

Marshall value, Lawele granular asphalt, candlenut oil, asbuton, modifier for Buton asphaltAbstract

Lawele Granular Asphalt (LGA) is a Buton asphalt product derived from the Lawele area in Central Sulawesi, Indonesia. Although it possesses great potential, LGA utilization has not been fully maximized. One of the challenges is the need for a modifier to extract asphalt from the minerals within LGA. Candlenut oil is a potential modifier that can be used with LGA in Cold Paving Hot Mix Asbuton (CPHMA) due to its similar polarity. Therefore, the aim of this research is to evaluate the performance of Lawele Granular Asphalt (LGA) with candlenut oil as a modifier in Cold Paving Hot Mix Asbuton (CPHMA).

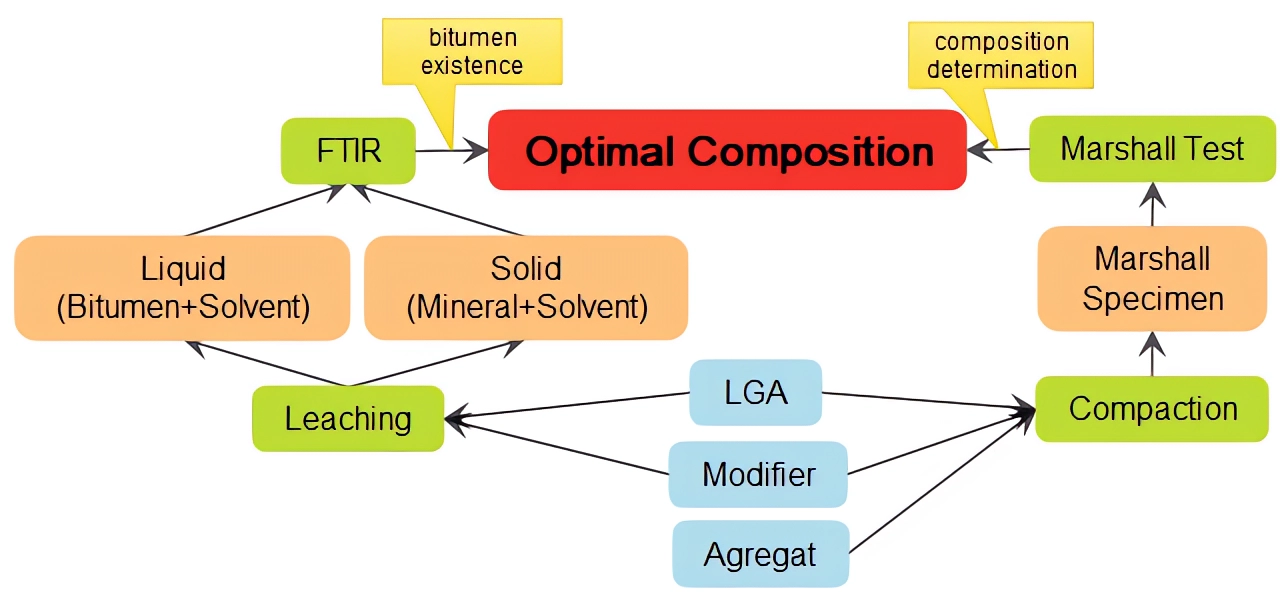

The Marshall test was conducted to assess the performance of CPHMA with candlenut oil as a modifier. Furthermore, several variations were examined, including the quantity of the modifier, duration of heating and compaction, heating temperature, and storage duration, using seven different mixtures and three storage periods. The optimal composition produced a Marshall value of 687.68 kg, which increased with a longer mixing duration and higher heating temperature.

The results showed that the Marshall value met the standards for CPHMA in Indonesia, as well as for VIM, VMA, VFB, and Flow values. The low flow indicated the density of the CPHMA pavement, while the MQ value showed its ability to withstand deformation of 200.13 kg/1 cm. The behavior of Marshall resistance was supported by Fourier transform infrared (FTIR) spectra, which exhibited similar compound groups between asphalt and the leached results of LGA with candlenut oil, indicating the presence of asphalt (binder). There was a slight decrease in the Marshall value after a 7-day duration, showing an increase after a 21-day storage period. Therefore, candlenut oil served as a viable alternative modifier for LGA

Supporting Agency

- The authors are grateful to: 1. Researcher Team (D. J. Djoko H. Santjojo, Ahmadiansyah, R. Abednego Rumbay, C. Chandra Septyan), 2. PT. KAN for providing LGA.

References

- Zalman, Yulianto, B., Setyawan, A. (2017). Assessing the durability of North Buton Asphalt seal with Polymer Modified and Rejuvenation in warm mixture design. IOP Conference Series: Materials Science and Engineering, 176, 012034. doi: https://doi.org/10.1088/1757-899x/176/1/012034

- Road Work Supply Chain Using Buton Asphalt (2018). Directorate of Institutional Development and Construction Services Resources. Surabaya.

- Sumantoro, I. (2021). Imported Oil Asphalt Prices Rise, Who Cares. Available at: https://www.indonesiana.id/read/151013/harga-aspal-minyak-impor-naik-untuk-peduli#

- Pravianto, W. (2013). Asbuton Technology Collection. Bandung: Pusjatan.

- Baisa, H. L. (2022). Interview. Malang.

- Nugroho, J., Darmadi (2019). Comparison of Asphalt Pavement Design Costs with Design Life for the Cilegon-Cibaliung and Citereup-Tanjung Lesung City Boundary Road Projects. J. Tek. SIpil - Arsit., 18 (2), 54–61.

- Cunanan, P. (2018). Carbon Intensive Industries - The Industry Sectors that Emit The Most Carbon. Eco Warrior Princess. Available at: https://ecowarriorprincess.net/2018/04/carbon-intensive-industries-industry-sectors-emit-the-most-carbon/

- Buton Asphalt Mine. PT. Putindo Bintech. Available at: http://bai.co.id/about-commitment.php

- Affandi, F. (2009). Properties of Hot Asphalt Mixture With Granulated Asbuton. J. Jalan–Jembatan, 26 (2), 1–14.

- Suaryana, N., Widayat, D., Kurniadji, Dachlan, T. A., Yamin, A. (2004). Hot Mix Asphalt Work Manual.

- DPU Dirjen Bina Marga (2006). Use of Asbuton Book 4 Warm Asphalt Mixture with Granular Asbuton. Jakarta.

- Djakfar, L., Wisnumurti, Khamelda, L. (2022). Performance of CPHMA Incorporating Vegetable Oil as Asbuton Solution. Key Engineering Materials, 912, 1–16. doi: https://doi.org/10.4028/p-c85t83

- Ketaren, S. (1986). Food Oils and Fats. Jakarta: UI-Press.

- Qi, Z., Abedini, A., Sharbatian, A., Pang, Y., Guerrero, A., Sinton, D. (2018). Asphaltene Deposition during Bitumen Extraction with Natural Gas Condensate and Naphtha. Energy & Fuels, 32 (2), 1433–1439. doi: https://doi.org/10.1021/acs.energyfuels.7b03495

- Xu, L., Abedini, A., Qi, Z., Kim, M., Guerrero, A., Sinton, D. (2018). Pore-scale analysis of steam-solvent coinjection: azeotropic temperature, dilution and asphaltene deposition. Fuel, 220, 151–158. doi: https://doi.org/10.1016/j.fuel.2018.01.119

- Jia, C., Batterman, S. (2010). A Critical Review of Naphthalene Sources and Exposures Relevant to Indoor and Outdoor Air. International Journal of Environmental Research and Public Health, 7 (7), 2903–2939. doi: https://doi.org/10.3390/ijerph7072903

- Batterman, S., Chin, J.-Y., Jia, C., Godwin, C., Parker, E., Robins, T. et al. (2012). Sources, concentrations, and risks of naphthalene in indoor and outdoor air. Indoor Air, 22 (4), 266–278. doi: https://doi.org/10.1111/j.1600-0668.2011.00760.x

- Ge, D., You, Z., Chen, S., Liu, C., Gao, J., Lv, S. (2019). The performance of asphalt binder with trichloroethylene: Improving the efficiency of using reclaimed asphalt pavement. Journal of Cleaner Production, 232, 205–212. doi: https://doi.org/10.1016/j.jclepro.2019.05.164

- Kendale, J. C., Valentín, E. M., Woerpel, K. A. (2014). Solvent Effects in the Nucleophilic Substitutions of Tetrahydropyran Acetals Promoted by Trimethylsilyl Trifluoromethanesulfonate: Trichloroethylene as Solvent for Stereoselective C- and O-Glycosylations. Organic Letters, 16 (14), 3684–3687. doi: https://doi.org/10.1021/ol501471c

- Ulanova, T. S., Nurislamova, T. V., Popova, N. A., Mal’tseva, O. A. (2020). Working out a procedure for determining potentially hazardous volatile organic compounds (trichloroethylene and tetrachloroethylene) in ambient air. Health Risk Analysis, 4, 113–120. doi: https://doi.org/10.21668/health.risk/2020.4.13.eng

- Mikhailenko, P., Ataeian, P., Baaj, H. (2019). Extraction and recovery of asphalt binder: a literature review. International Journal of Pavement Research and Technology, 13 (1), 20–31. doi: https://doi.org/10.1007/s42947-019-0081-5

- Lopez-Alvarez, B., Villegas-Guzman, P., Peñuela, G. A., Torres-Palma, R. A. (2016). Degradation of a Toxic Mixture of the Pesticides Carbofuran and Iprodione by UV/H2O2: Evaluation of Parameters and Implications of the Degradation Pathways on the Synergistic Effects. Water, Air, & Soil Pollution, 227 (6). doi: https://doi.org/10.1007/s11270-016-2903-2

- Tu, Z., Zhou, Y., Zhou, J., Han, S., Liu, J., Liu, J. et al. (2023). Identification and Risk Assessment of Priority Control Organic Pollutants in Groundwater in the Junggar Basin in Xinjiang, P.R. China. International Journal of Environmental Research and Public Health, 20 (3), 2051. doi: https://doi.org/10.3390/ijerph20032051

- Oliviero Rossi, C., Caputo, P., De Luca, G., Maiuolo, L., Eskandarsefat, S., Sangiorgi, C. (2018). 1H-NMR Spectroscopy: A Possible Approach to Advanced Bitumen Characterization for Industrial and Paving Applications. Applied Sciences, 8 (2), 229. doi: https://doi.org/10.3390/app8020229

- Mirazi, N., Movassagh, S.-N., Rafieian-Kopaei, M. (2016). The protective effect of hydro-alcoholic extract of mangrove (Avicennia marina L.) leaves on kidney injury induced by carbon tetrachloride in male rats. Journal of Nephropathology, 5 (4), 118–122. doi: https://doi.org/10.15171/jnp.2016.22

- Ganie, S. A., Haq, E., Hamid, A., Qurishi, Y., Mahmood, Z., Zargar, B. A. et al. (2011). Carbon tetrachloride induced kidney and lung tissue damages and antioxidant activities of the aqueous rhizome extract of Podophyllum hexandrum. BMC Complementary and Alternative Medicine, 11 (1). doi: https://doi.org/10.1186/1472-6882-11-17

- Deng, J.-S., Chang, Y.-C., Wen, C.-L., Liao, J.-C., Hou, W.-C., Amagaya, S. et al. (2012). Hepatoprotective effect of the ethanol extract of Vitis thunbergii on carbon tetrachloride-induced acute hepatotoxicity in rats through anti-oxidative activities. Journal of Ethnopharmacology, 142 (3), 795–803. doi: https://doi.org/10.1016/j.jep.2012.06.003

- Adekomi, D., Oyesomi, T., Ajao, M., Ojo, O., Onikanni, S. (2013). Impact of liver damage on the histoarchitectural profile of the cerebellar cortex in rats. African Journal of Cellular Pathology, 1 (1), 1–8. doi: https://doi.org/10.5897/ajcpath13.005

- Cetinkaya, A., Kantarceken, B., Bulbuloglu, E., Kurutas, E. B., Ciralik, H., Atli, Y. (2013). The effects of L-carnitine and N-acetylcysteine on carbontetrachloride induced acute liver damage in rats. Bratislava Medical Journal, 114 (12), 682–688. doi: https://doi.org/10.4149/bll_2013_145

- Hudianti, M. (2007). Variation Modifier Processing Method on Lasbutag Cold Mix for High Quality Road Hardening.

- Gertenbach, D. D. (2002). Solid-Liquid Extraction Technologies for Manufacturing Nutraceuticals. Functional Foods: Bioachemical and Processing Aspects. CRC Press, 332–365.

- Kementerian PUPR Dirjen Bina Marga (2016). CPHMA Interim Specifications. Bandung.

- Djakfar, L., Wisnumurti, Khamelda, L. (2020). Methods of Making Laboratory Scale CPHMA Specimens. International Journal of Engineering Trends and Technology (IJETT). Available at: https://ijettjournal.org/special-issues/ijett-aiic102

- Direktorat Jenderal Bina Marga (2016). Spesifikasi Khusus CPHMA 2016. Jakarta.

- Marga, B. (1991). Asphalt Mixture Testing Method with the Marshall Tool. SNI 06-2489-1991.

- SNI 03-6894-2002. Method for Testing The Asphalt Content of Asphalt Mixtures Using a Centrifuge. Available at: https://binamarga.pu.go.id/index.php/nspk/detail/sni-03-6894-2002-metode-pengujian-kadar-aspal-dan-campuran-beraspal-dengan-cara-sentrifus

- Laboratorium Rekayasa Jalan ITB (2001). Road Engineering Laboratory Ledger. Bandung: ITB.

- Caroles, L., Tumpu, M., Rangan, P. R., Mansyur (2021). Marshall properties of LASBUTAG asphalt mixes with pertalite as a modifier. IOP Conference Series: Earth and Environmental Science, 871 (1), 012064. doi: https://doi.org/10.1088/1755-1315/871/1/012064

- Nawir, D., Mansur, A. Z. (2021). The Impact of HDPE Plastic Seeds on the Performance of Asphalt Mixtures. Civil Engineering Journal, 7 (9), 1569–1581. doi: https://doi.org/10.28991/cej-2021-03091744

- Sukirman, S. (2016). Hot Mix Asphalt Concrete. Bandung: Institut Teknologi Nasional Bandung.

- Suyuti, R. A., Sumabrata, R. J., Hadiwardoyo, S. P., Iskandar, D. (2019). The use of reclaimed asphalt pavement by adding retona asbuton on asphalt concrete wearing course using the warm mix asphalt method. AIP Conference Proceedings. doi: https://doi.org/10.1063/1.5112431

- Sastrohamidjojo, H. (2018). Basic Chemistry. Yogyakarta: Gadjah Mada University Press.

- Redelius, P. (2009). Asphaltenes in Bitumen, What They Are and What They Are Not. Road Materials and Pavement Design, 10 (sup1), 25–43. doi: https://doi.org/10.1080/14680629.2009.9690234

- Faradiba, N. (2021). Difference between Organic and Inorganic Compounds. Available at: https://www.kompas.com/sains/read/2021/12/28/204500623/perbedaan-senyawa-organik-dan-anorganik

- Djakfar, L., Khamelda, L. (2023). Metode Pengujian untuk Pelarut Asbuton Berbasis-Minyak Kemiri. Indonesia.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Lila Khamelda, Ludfi Djakfar, Wisnumurti

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.