Identifying applicability viscoelastic systems in the context of improving well casing processe

DOI:

https://doi.org/10.15587/1729-4061.2023.292252Keywords:

oil well cement, cement composite materials, basalt fiber, strength, deformation characteristicsAbstract

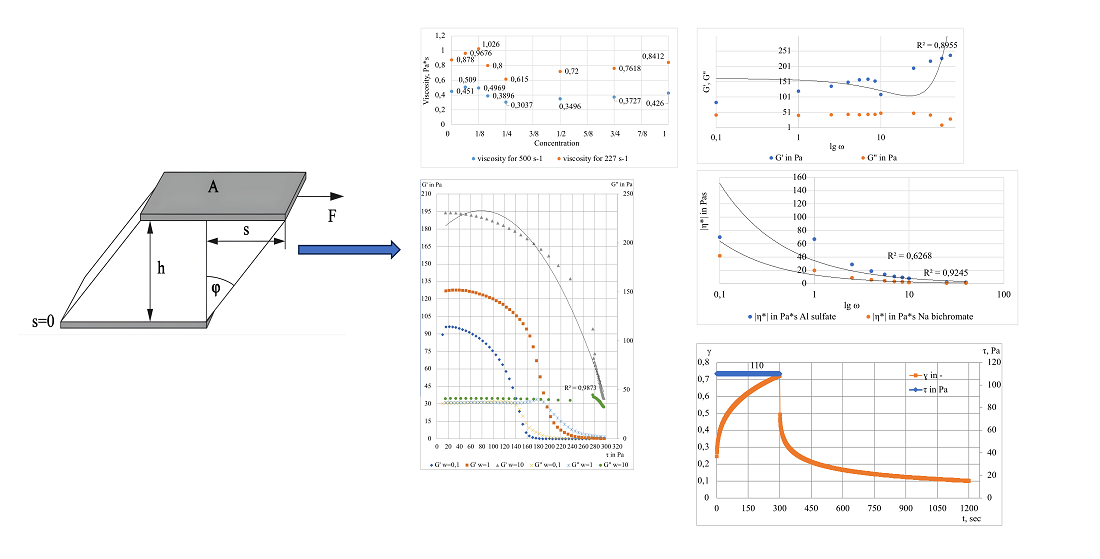

The object of research in this study is viscoelastic systems used as spacer systems in well casing during drilling. Polymer network-metal ion systems display distinctive properties, facilitating effective well coverage through their normal stresses.

The primary problem addressed in this research was optimizing viscoelastic system composition for well casing. Researchers sought the ideal sodium dichromate concentration to maximize viscosity in polyacrylamide-based spacer fluids. This optimization is crucial for enhancing casing cementing quality, especially in challenging geological conditions.

Utilizing a precise HAAKE MARS III rheometer, various tests, including shear, oscillatory, frequency, creep, and recovery tests, were performed to assess viscoelastic system rheology. Obtained results of optimal deformation interval for a solution with sodium bichromate is 40 Pa and aluminum sulfate, the yield strength was equal to 110 Pa.

This research optimized cross-linker concentration, increasing spacer system viscosity. This enhancement improves well cementing efficiency and allows for operation in challenging geological conditions. The precise rheometer unveiled previously unexplored rheological characteristics.

The optimized viscoelastic spacer fluid is invaluable in well casing, especially in challenging geological settings. This research guides the design of process fluids, enhancing casing cementing quality, and improving drilling efficiency and safety. Engineers and researchers can leverage the rheological data for informed decisions and better field performance

Supporting Agency

- We thank professor Agzamov Farit Akramovich for the necessary materials provided and the joint work carried out.

References

- Kabdushev, A., Delikesheva, D., Korgasbekov, D., Manapbayev, B., Kalmakhanova, M. (2023). Identifying the influence of basalt fiber reinforcement on the deformation and strength characteristics of cement stone. Eastern-European Journal of Enterprise Technologies, 5 (6 (125)), 58–65. doi: https://doi.org/10.15587/1729-4061.2023.288551

- Doan, A., Holley, A., Kellum, M., Dighe, S., Arceneaux, C., Conrad, K. (2018). Application of an Innovative Spacer System Designed for Optimal Performance in HTHP Wells. Paper presented at the IADC/SPE Drilling Conference and Exhibition. doi: https://doi.org/10.2118/189682-ms

- Brandl, A., Doan, A. A., Alegria, A. E. (2017). Advances in Spacer Technologies for Improved Zonal Isolation Results in Challenging Deep Deviated HPHT Wells Containing Heavy Oil Based Muds. Paper presented at the SPE Kuwait Oil & Gas Show and Conference. doi: https://doi.org/10.2118/187658-ms

- Gumerova, G. R., Yarkeeva, N. R. (2017). Technology of application of crosslinked polymeric compositions. Oil and Gas Business, 2, 63–79. doi: https://doi.org/10.17122/ogbus-2017-2-63-79

- Docherty, K. E. et al. (2016). Mud Removal – Clearing the Way for Effective Cementing. Oilfield Review, 28 (1), 20–25.

- Elochukwu, H., Samansu Douglas, E., Chikere, A. O. (2022). Evaluation of methyl ester sulphonate spacer fluid additive for efficient wellbore clean-up. Energy Geoscience, 3 (1), 73–79. doi: https://doi.org/10.1016/j.engeos.2021.11.002

- Kędzierski, M., Rzepka, M., Kremieniewski, M. (2019). The effects of cement slurry contamination with the drilling mud and spacer fluid on its setting. Nafta-Gaz, 75 (11), 691–699. doi: https://doi.org/10.18668/ng.2019.11.04

- Li, J., Li, Z., Tang, S., Sun, J., Wu, H., Su, D., Chen, W. (2020). Mechanism for the promotional effect of a novel solidifiable spacer fluid system on the cementation quality of cement sheath/formation interface. Energy Science & Engineering, 8 (12), 4212–4221. doi: https://doi.org/10.1002/ese3.805

- Li, L. et al. (2016). A novel spacer system to prevent lost circulation in cementing applications. Proceedings of the 2016 AADE Fluids Technical Conference and Exhibition. Houston.

- Ghoussoub, Y. E., Zerball, M., Fares, H. M., Ankner, J. F., von Klitzing, R., Schlenoff, J. B. (2018). Ion distribution in dry polyelectrolyte multilayers: a neutron reflectometry study. Soft Matter, 14 (9), 1699–1708. doi: https://doi.org/10.1039/c7sm02461d

- Li, L., Alegria, A., Doan, A. A., Kellum, M. G., Castanedo, R. (2016). Application of a Novel Cement Spacer with Biodegradable Polymer to Improve Zonal Isolation in HTHP Wells. Paper presented at the Offshore Technology Conference. doi: https://doi.org/10.4043/27048-ms

- Ramos, V., Doan, A., Ekwue, A.-M., Kellum, M. (2020). An Innovative Spacer System Designed with Biodegradeable Polymer and Loss Circulation Material to Aid in Formation Damage Control. Paper presented at the SPE International Conference and Exhibition on Formation Damage Control. doi: https://doi.org/10.2118/199242-ms

- Quintero, L., Passanha, W. D., Aubry, E., Poitrenaud, H. (2015). Advanced Microemulsion Cleaner Fluid Applications in Deepwater Wells. Paper presented at the OTC Brasil. doi: https://doi.org/10.4043/26344-ms

- Curbelo, F. D. S., Garnica, A. I. C., Araújo, E. A., Paiva, E. M., Cabral, A. G., Araújo, E. A., Freitas, J. C. O. (2018). Vegetable oil-based preflush fluid in well cementing. Journal of Petroleum Science and Engineering, 170, 392–399. doi: https://doi.org/10.1016/j.petrol.2018.06.061

- Kremieniewski, M., Kędzierski, M., Błaż, S. (2021). Increasing the Efficiency of Sealing the Borehole in Terms of Spacer Pumping Time. Energies, 14 (20), 6702. doi: https://doi.org/10.3390/en14206702

- Loginova, M. Ye., Agzamov, F. A., Ismakov, R. A. (2022). Investigation of viscoelastic properties of buffer fluids to improve the quality of well anchoring. Prom. Proizvod. Ispol’z. Elastomerov, 3-4, 39–48. doi: https://doi.org/10.24412/2071-8268-2022-3-4-39-48

- Pernites, R., Brady, J., Padilla, F., Clark, J., McNeilly, C., Iqbal, W. et al. (2019). Unconventional Advanced High Performance Micromaterial for Enhancing Drilling Mud Cleaning Performance of Spacer Fluids in Horizontal Wells: From Laboratory Development to Field Applications. Proceedings of the 7th Unconventional Resources Technology Conference. doi: https://doi.org/10.15530/urtec-2019-60

- Fang, E., Li, H., Zhang, H., Chen, X., Luo, Y., Gu, J. (2020). Development and performance evaluation of a low temperature low density solidifiable spacer fluid. Drilling Fluid and Completion Fluid, 37 (1), 86–92. Available at: http://www.zjyywjy.com.cn/en/article/doi/10.3969/j.issn.1001-5620.2020.01.014

- Tabatabaee Moradi, S. S., Nikolaev, N., Nikolaeva, T. (2020). Development of spacer fluids and cement slurries compositions for lining of wells at high temperatures. Journal of Mining Institute, 242, 174. doi: https://doi.org/10.31897/pmi.2020.2.174

- Sarap, G. D., Sivanandan, M., Patil, S., Deshpande, A. P. (2009). The Use of High-Performance Spacers for Zonal Isolation in High-Temperature High-Pressure Wells. All Days. doi: https://doi.org/10.2118/124275-ms

- Théron, B. E., Bodin, D., Fleming, J. (2002). Optimization of Spacer Rheology Using Neural Network Technology. All Days. doi: https://doi.org/10.2118/74498-ms

- Cao, C., Pu, X., Wang, G., Zhao, Z. (2020). True rheological behaviours of spacer fluid with consideration of wall slip effect. International Journal of Oil, Gas and Coal Technology, 23 (1), 30. doi: https://doi.org/10.1504/ijogct.2020.104969

- Brand, F., Peixinho, J., Nouar, C. (2001). A Quantitative Investigation of the Laminar-to-Turbulent Transition: Application to Efficient Mud Cleaning. All Days. doi: https://doi.org/10.2118/71375-ms

- Koptiaeva, E. I., Karazeev, D. V., Strizhnev, V. A., Vezhnin, S. A., Telin, A. G. (2014). New cross-linked polymer compositions at the basis of partially hydrolyzed PAA for water shut-off and conformance control. Oil. Gas. Innovations, 10 (189), 45–49.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Arman Kabdushev, Dinara Delikesheva, Darkhan Korgasbekov, Bauyrzhan Manapbayev, Marzhan Kalmakhanova

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.