Development of new C, S, N-containing plastic lubricants based on products from industrial waste integrated processing

DOI:

https://doi.org/10.15587/1729-4061.2024.296622Keywords:

integrated technologies, industrial waste, plastic lubricants, bis-(diethyldithiocarbamate)copper(II), sorption, modified surfaceAbstract

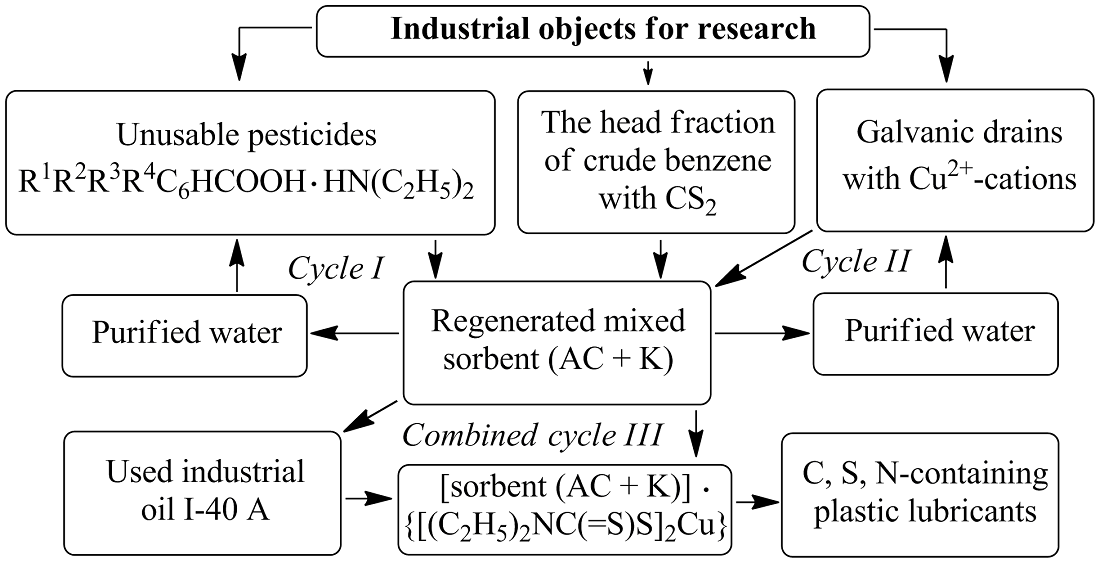

The object of this research is the integrated processing of industrial waste from various industries, which makes it possible to reduce the use of material and energy resources and improve the ecological state of the environment. Waste from the chemical, petrochemical, and machine-building industries was subject to integrated technological processing.

The common link that united the investigated complex technological cycles was the use of a regenerated mixed sorbent (activated carbon+kieselguhr), on the surface of which topochemical transformations of chemicals that were part of industrial waste took place. Using a regenerated mixed sorbent, exhausted industrial oil which was the mineral basis of the developed new C, S, N-containing plastic lubricants was purified. In particular, we have established the conditions for obtaining diethyl ammonium chloride from unusable pesticides of the formula R1R2R3R4C6HCOOH∙HN(C2H5)2, whose topochemical interaction on the surface of the mixed sorbent leads to the formation of a sorbed fragment [sorbent (activated carbon+kieselguhr)]∙[(C2H5)2NC(=S)SK]. Subsequent interaction of aqueous solutions containing copper(II) ions with such a fragment leads to the formation of bis–(diethyldithiocarbamate)copper(II) on the surface of mixed sorbent. The resulting substances of the general composition [sorbent (activated carbon + kieselguhr)]∙{[(С2H5)2NC(=S)S]2Cu} were studied as thickeners and active polyfunctional components of the obtained plastic lubricants. Research into the tribological properties of new C, S, N-containing plastic lubricants showed their high anti-wear and heat-resistant properties and the possibility of effective use in highly loaded friction nodes

References

- Ishchuk, Yu. L. (1996). Sostav, struktura i svoystva plastichnyh smazok. Kyiv: Naukova dumka, 508.

- Ranskyi, A. P., Boichenko, S. V., Hordienko, O. A., Didenko, N. O., Voloshynets, V. A. (2012). Kompozytsiyni mastylni materialy na osnovi tioamidiv ta yikh kompleksnykh spoluk. Syntez. Doslidzhennia. Vykorystannia. Vinnytsia: VNTU, 328. Available at: https://press.vntu.edu.ua/index.php/vntu/catalog/book/207

- Holmberg, K., Erdemir, A. (2017). Influence of tribology on global energy consumption, costs and emissions. Friction, 5 (3), 263–284. https://doi.org/10.1007/s40544-017-0183-5

- Heshmati, A. (2016). A Review of the Circular Economy and its Implementation. SSRN Electronic Journal. https://doi.org/10.2139/ssrn.2713032

- Shao, X., Wang, L., Yang, Y., Yang, T., Deng, G., He, Y. et al. (2023). Influence of preload on the tribological performance of MoS2/GO composite lubricating coating. Tribology International, 181, 108306. https://doi.org/10.1016/j.triboint.2023.108306

- Torres, H., Rodríguez Ripoll, M., Prakash, B. (2017). Tribological behaviour of self-lubricating materials at high temperatures. International Materials Reviews, 63 (5), 309–340. https://doi.org/10.1080/09506608.2017.1410944

- Tonge, P., Roy, A., Patel, P., Beall, C. J., Stoyanov, P. (2022). Tribological Evaluation of Lead-Free MoS2-Based Solid Film Lubricants as Environmentally Friendly Replacements for Aerospace Applications. Lubricants, 10 (1), 7. https://doi.org/10.3390/lubricants10010007

- Vazirisereshk, M. R., Martini, A., Strubbe, D. A., Baykara, M. Z. (2019). Solid Lubrication with MoS2: A Review. Lubricants, 7 (7), 57. https://doi.org/10.3390/lubricants7070057

- Savan, A., Pflüger, E., Voumard, P., Schröer, A., Simmonds, M. (2000). Modern solid lubrication: Recent developments and applications of MoS2. Lubrication Science, 12 (2), 185–203. https://doi.org/10.1002/ls.3010120206

- Donnet, C., Martin, J. M., Le Mogne, Th., Belin, M. (1996). Super-low friction of MoS2 coatings in various environments. Tribology International, 29 (2), 123–128. https://doi.org/10.1016/0301-679x(95)00094-k

- Khudoyarova, O., Gordienko, O., Blazhko, A., Sydoruk, T., Ranskiy, A. (2020). Desulfurization of Industrial Water-Alkaline Solutions and Receiving new Plastic Oils. Journal of Ecological Engineering, 21 (6), 61–66. https://doi.org/10.12911/22998993/123254

- Khudoyarova, O., Ranskiy, A., Korinenko, B., Gordienko, O., Sydoruk, T., Didenko, N., Kryklyvyi, R. (2021). Integration of Technological Cycles of Industrial Waste Processing. Journal of Ecological Engineering, 22 (6), 209–214. https://doi.org/10.12911/22998993/137821

- Ranskiy, A., Gordienko, O., Sakalova, H., Sydoruk, T., Titov, T., Blazhko, O. (2023). Complex Sorption Treatment of Industrial Waste and Production of Plastic Lubricants. Ecological Engineering & Environmental Technology, 24 (3), 54–59. https://doi.org/10.12912/27197050/159628

- Khudoyarova, O. S., Gordienko, O. A., Sydoruk, T. I., Titov, T. S., Ranskiy, A. P. (2020). Surface modification of mixed sorbents with sulfide ions for purification of galvanic wash water of copper plating process. Proceedings of the NTUU “Igor Sikorsky KPI”. Series: Chemical Engineering, Ecology and Resource Saving, 2, 36–46. https://doi.org/10.20535/2617-9741.2.2020.208054

- Planet. The Circular Carbon Economy. Available at: https://korea.aramco.com/en/making-a-difference/planet/the-circular-carbon-economy

- Mandziuk, I. A., Ivanishena, T. V. (2002). Doslidzhennia khimichnoho retsyklinhu – hlikolizu polietylentereftalatu. Visnyk Tekhnolohichnoho universytetu Podillia, 5, 186–189.

- Ranskiy, A. P., Khudoyarova, O. S., Gordienko, O. A., Titov, T. S., Kryklyvyi, R. D. (2019). Regeneration of Sorbents Mixture After the Purification of Recycled Water in Production of Soft Drinks. Journal of Water Chemistry and Technology, 41 (5), 318–321. https://doi.org/10.3103/s1063455x19050084

- Titov, T. S., Dykha, O. V., Gordienko, O. A., Gruzdeva, O. V. (2013). Analysis of antiwear properties of N, N-dialkyldithiocarbamates of some 3d-metals as additives for industrial oils. Problems of Tribology, 67 (1), 105–113. Available at: https://tribology.khnu.km.ua/index.php/ProbTrib/article/view/154

- Hordienko, O. A., Ranskyi, A. P., Yevsieieva, M. V., Avdienko, T. M. (2011). Utylizatsiya pestytsydnoho preparatu Banvel. Voprosy himii i himicheskoy tehnologii, 6, 162–167. Available at: https://ir.lib.vntu.edu.ua/handle/123456789/940

- Nakamoto, K. (1970). Infrared Spectra of Inorganic and Coordination Compounds. John Wiley & Sons, 338.

- Xie, Y., Bertoni, G., Riedinger, A., Sathya, A., Prato, M., Marras, S. et al. (2015). Nanoscale Transformations in Covellite (CuS) Nanocrystals in the Presence of Divalent Metal Cations in a Mild Reducing Environment. Chemistry of Materials, 27 (21), 7531–7537. https://doi.org/10.1021/acs.chemmater.5b03892

- Turo, M. J., Macdonald, J. E. (2014). Crystal-Bound vs Surface-Bound Thiols on Nanocrystals. ACS Nano, 8 (10), 10205–10213. https://doi.org/10.1021/nn5032164

- Xie, Y., Riedinger, A., Prato, M., Casu, A., Genovese, A., Guardia, P. et al. (2013). Copper Sulfide Nanocrystals with Tunable Composition by Reduction of Covellite Nanocrystals with Cu+ Ions. Journal of the American Chemical Society, 135 (46), 17630–17637. https://doi.org/10.1021/ja409754v

- Coughlan, C., Ibáñez, M., Dobrozhan, O., Singh, A., Cabot, A., Ryan, K. M. (2017). Compound Copper Chalcogenide Nanocrystals. Chemical Reviews, 117 (9), 5865–6109. https://doi.org/10.1021/acs.chemrev.6b00376

- Tertyh, V. A., Belyakova, L. A. (1991). Himicheskie reaktsii s uchastiem poverhnosti kremnezema. Kyiv: Naukova dumka, 246. Available at: https://www.twirpx.com/file/265212/

- da Silva, M. A., Dreiss, C. A. (2015). Soft nanocomposites: nanoparticles to tune gel properties. Polymer International, 65 (3), 268–279. https://doi.org/10.1002/pi.5051

- Voevodin, A., Zabinski, J. (2005). Nanocomposite and nanostructured tribological materials for space applications. Composites Science and Technology. https://doi.org/10.1016/j.compscitech.2004.10.008

- Wang, G. P., Chang, T. C., Hong, Y. S., Chiu, Y. S. (2002). Dynamics of novel hydrogen-bonded acidic fluorinated poly(amide-imide-silica) hybrids studied by solid-state NMR. Polymer, 43 (8), 2191–2200. https://doi.org/10.1016/s0032-3861(02)00016-2

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Anatoliy Ranskiy, Olha Sandul, Olga Gordienko, Natalia Didenko, Taras Titov

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.