Designing energy-efficient hardware and technological structure of absorption refrigeration units for ammonia production

DOI:

https://doi.org/10.15587/1729-4061.2024.297717Keywords:

ammonia synthesis, absorption-refrigeration unit, heat disposal, energy efficiency of ammonia productionAbstract

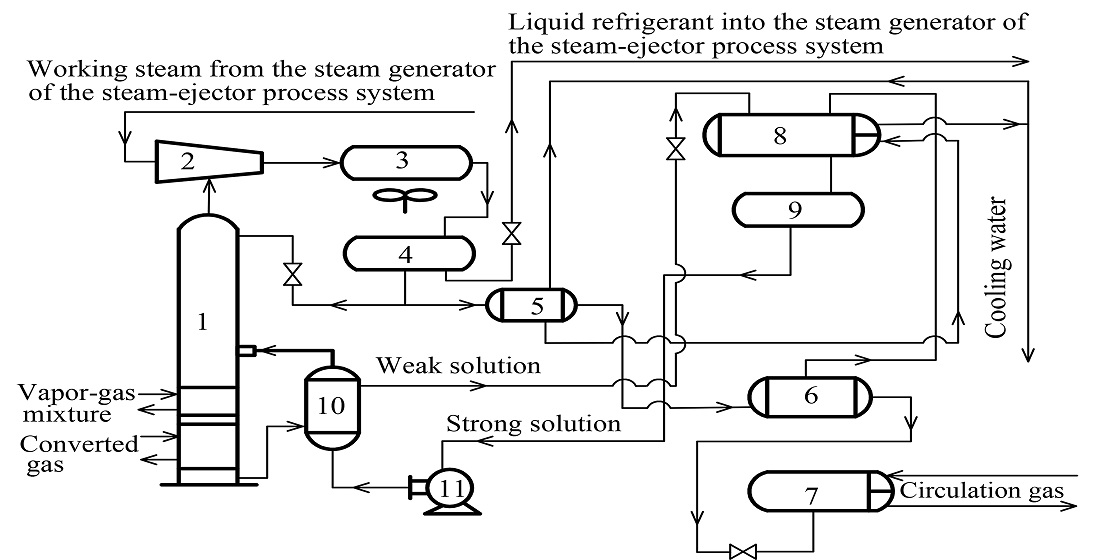

The object of research is the equipment and technological design of absorption refrigeration units (ARUs) for the technological system of secondary condensation of large-scale ammonia production. Improving the energy efficiency of ARU is an urgent problem in the general process of reducing operating costs for natural gas in these industries as a whole.

Based on the results of analytical studies, the feasibility of combining absorption-refrigeration and vapor-ejector cycles was substantiated, which ensures a decrease in the boiling temperature of a weak water-ammonia solution in the cube of the generator-rectifier and an increase in the condensation pressure in the ARU cycle. Under such circumstances, it becomes possible to increase the concentration of the refrigerant due to the rectification of steam with a part of the liquid refrigerant without using a pump with the removal of the dephlegmator from the ARU circuit.

Experimental studies and material-thermal calculations of ARU cycles were carried out to determine the basis of comparison and the proposed version of the ARU scheme. It has been proven that the new technological design of ARU provides an increase in cooling capacity from 3.22 MW to 3.6 MW (by 12 %), the thermal coefficient from 0.527 to 0.551 (by 4.6 %), a decrease in the circulation ratio from 7.77 to 7.1 (by 8 %), and a decrease in the secondary condensation temperature by 2.5 ℃.

It is shown that for the proposed version of the technological design of ARU, there is a change in specific costs – an increase in electricity by 1.48 kWh/t NH3 and a decrease in natural gas by 0.41 nm3/t NH3. Taking into account existing cost indicators for natural gas and electricity, the application of the proposed technology ensures a decrease in annual operating costs by UAH 7 million (USD 185,000), and therefore an increase in the economy of ammonia production as a whole

References

- Heidlage, M., Pfromm, P. (2015). Novel Thermochemical Synthesis of Ammonia and Syngas from Natural Gas. 2015 AIChE Annual Meeting Proceedings. Available at: https://www.aiche.org/conferences/aiche-annual-meeting/2015/proceeding/paper/517b-novel-thermochemical-synthesis-ammonia-and-syngas-natural-gas

- Amhamed, A. I., Shuibul Qarnain, S., Hewlett, S., Sodiq, A., Abdellatif, Y., Isaifan, R. J., Alrebei, O. F. (2022). Ammonia Production Plants—A Review. Fuels, 3 (3), 408–435. https://doi.org/10.3390/fuels3030026

- Babichenko, A., Babichenko, Yu., Kravchenko, Ya., Krasnikov, I. (2021). Algorithmic support for decision-making on the efficiency of operation of absorption and refrigeration plants of ammonia production. Integrated Technologies and Energy Saving, 4, 13–21. https://doi.org/10.20998/2078-5364.2021.4.02

- Babichenko, A., Babichenko, J., Kravchenko, Y., Velma, S., Krasnikov, I., Lysachenko, I. (2018). Identification of heat exchange process in the evaporators of absorption refrigerating units under conditions of uncertainty. Eastern-European Journal of Enterprise Technologies, 1 (2 (91)), 21–29. https://doi.org/10.15587/1729-4061.2018.121711

- ASHRAE Handbook: Refrigeration (2010). American Society of Heating, Refrigerating and Air-Conditioning Engineers, 758.

- Wang, R., Wang, L., Wu, J. (2014). Adsorption Refrigeration Technology. John Wiley & Sons. https://doi.org/10.1002/9781118197448

- Babichenko, A. K., Toshynskyi, V. I. (2009). With the rise of the effective operation of absorption - refrigeration units ammonia synthesis. Eastern-European Journal of Enterprise Technologies, 2 (4 (38)), 29–32. Available at: https://journals.uran.ua/eejet/article/view/5934

- Khalili, S., Garousi Farshi, L. (2020). Design and performance evaluation of a double ejector boosted multi-pressure level absorption cycle for refrigeration. Sustainable Energy Technologies and Assessments, 42, 100836. https://doi.org/10.1016/j.seta.2020.100836

- Pacheco-Cedeño, J. S., Rodríguez-Muñoz, J. L., Ramírez-Minguela, J. J., Pérez-García, V. (2023). Comparison of an absorption-compression hybrid refrigeration system and the conventional absorption refrigeration system: Exergy analysis. International Journal of Refrigeration, 155, 81–92. https://doi.org/10.1016/j.ijrefrig.2023.08.003

- Kaynakli, O., Kilic, M. (2007). Theoretical study on the effect of operating conditions on performance of absorption refrigeration system. Energy Conversion and Management, 48 (2), 599–607. https://doi.org/10.1016/j.enconman.2006.06.005

- Dincer, I., Ratlamwala, T. A. H. (2016). Integrated Absorption Refrigeration Systems. In Green Energy and Technology. Springer International Publishing. https://doi.org/10.1007/978-3-319-33658-9

- Babichenko, A. K. (2009). Doslidzhennia hidrodynamiky roboty heneratora-rektyfikatora absorbtsiyno-kholodylnoi ustanovky ahrehatu syntezu amiaku. Eastern-European Journal of Enterprise Technologies, 6 (5 (42)), 27–29.

- Babichenko, A. K., Toshynskyi, V. I. (2009). Zastosuvannia matematychnoho modeliuvannia dlia diahnostyky pokaznykiv efektyvnosti protsesiv teplo-i masoobminu v absorberakh teplovykorystuiuchykh kholodylnykh ustanovok ahrehativ syntezu amiaku. Voprosy himii i himicheskoy tehnologii, 6, 107–111. Available at: http://vhht.dp.ua/wp-content/uploads/pdf/2009/6/Babichenko.pdf

- Syed, A. M. (2013). Jet compressor: design, analysis and optimization. LAP LAMBERT Academic Publishing, 132.

- Shukla, A., Mishra, A., Shukla, D., Chauhan, K. (2015). C.O.P Derivation and thermodynamic calculation of ammonia-water vapor absorption refrigeration system. International journal of mechanical engineering and technology, 6 (5), 72–81. Available at: https://iaeme.com/MasterAdmin/Journal_uploads/IJMET/VOLUME_6_ISSUE_5/IJMET_06_05_010.pdf

- Galimova, L. V., Kayl, V. Ya., Vedeneeva, A. I. (2015). Energy saving system absorption refrigerating machine of ammonia s ynthesis installation: performance analysis and thermodynamic perfection evaluation. Journal of International Academy of Refrigeration, 4 (57), 55–30.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Anatoliy Babichenko, Igor Krasnikov, Juliya Babichenko, Volodymyr Panasenko, Dmytro Snurnikov, Oleksii Shutynskyi

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.