Determining the influence of technological parameters of electron beam surfacing process on the microstructure and microhardness of Ti-6Al-4V alloy

DOI:

https://doi.org/10.15587/1729-4061.2024.297773Keywords:

electron beam surfacing, titanium alloy, Ti-6Al-4V, technological parameters, metallographic studiesAbstract

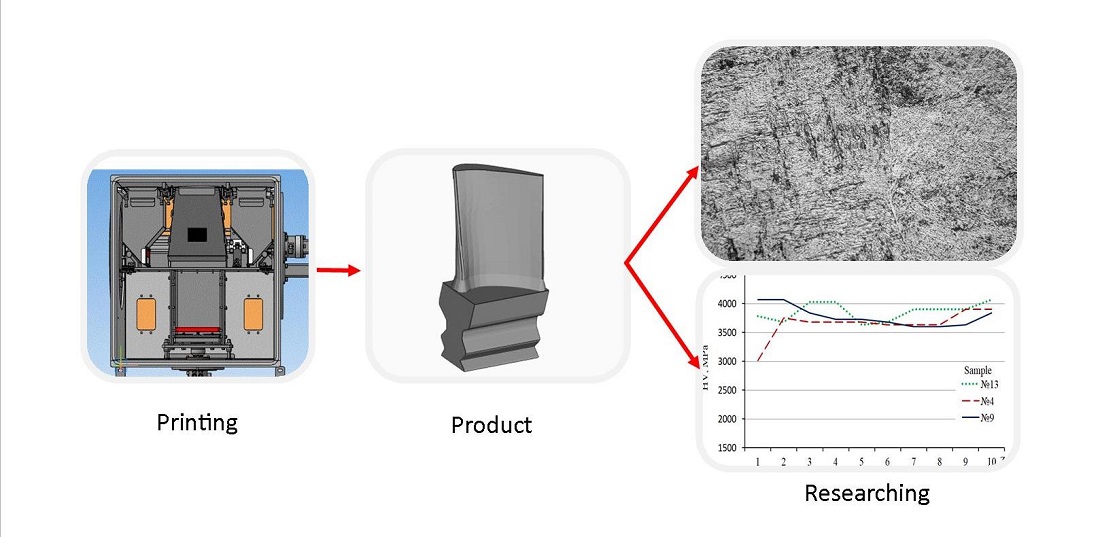

This paper reports the devised technology and equipment for manufacturing parts and assemblies with pre-defined properties by 3D printing methods. Underlying the technology is the application of a high-power electron beam to fuse metal powder in a vacuum chamber with the formation of successive layers that repeat the contours of the digital model of the product.

The object of research is the process of surfacing products made of Ti6Al4V titanium alloy powder. The influence of technological parameters (speed and power of the electron beam) on the formation of the structure of the deposited metal and its mechanical properties was investigated.

3 samples printed under 3 modes were studied: beam speed, 270, 540, and 780 mm/s; power, 240, 495, and 675 W, respectively. The beam energy density was 44.5 J/mm3; the trajectory displacement step was 0.2 mm; the dynamic focusing current Idf was –0.31 A; and the powder layer thickness was 0.1 mm.

The samples were examined by conventional methods. The structures were studied using an optical microscope, images were recorded with a camera. The Vickers hardness was measured with a microhardness meter in the direction from the technological supports to the surface of the sample, as well as along the surface of the product, and in the layers of the middle part of the sample.

It was established that the articles had a dense cast structure of surfaced metal. On all samples, large crystallites with a uniform lamellar-acicular structure of α´-phase with a small amount of β-phase are formed along the height, mostly without defects with uniform microhardness both along the height and along the surface.

It was determined that the surfacing mode at beam speed, 240 mm/s; power, 270 W is the most rational for practical use. Under this mode, a stronger structure is formed when it is crushed, reducing the width of the crystallites by 1.55 and 1.17 times compared to other modes

References

- Matviichuk, V. A., Nesterenkov, V. M., Berdnikova, O. M. (2022). Additive electron beam technology of manufacture of metal products from powder materials. Avtomatičeskaâ Svarka (Kiev), 2022 (2), 16–25. https://doi.org/10.37434/as2022.02.03

- Matviichuk, V., Nesterenkov, V., Berdnikova, O. (2022). Determining the influence of technological parameters of the electron-beam surfacing process on quality indicators. Eastern-European Journal of Enterprise Technologies, 1 (12 (115)), 21–30. https://doi.org/10.15587/1729-4061.2022.253473

- Wanjara, P., Backman, D., Sikan, F., Gholipour, J., Amos, R., Patnaik, P., Brochu, M. (2022). Microstructure and Mechanical Properties of Ti-6Al-4V Additively Manufactured by Electron Beam Melting with 3D Part Nesting and Powder Reuse Influences. Journal of Manufacturing and Materials Processing, 6 (1), 21. https://doi.org/10.3390/jmmp6010021

- Tan, X., Kok, Y., Tan, Y. J., Descoins, M., Mangelinck, D., Tor, S. B. et al. (2015). Graded microstructure and mechanical properties of additive manufactured Ti–6Al–4V via electron beam melting. Acta Materialia, 97, 1–16. https://doi.org/10.1016/j.actamat.2015.06.036

- Kok, Y., Tan, X., Tor, S. B., Chua, C. K. (2015). Fabrication and microstructural characterisation of additive manufactured Ti-6Al-4V parts by electron beam melting. Virtual and Physical Prototyping, 10 (1), 13–21. https://doi.org/10.1080/17452759.2015.1008643

- Kok, Y. H., Tan, X. P., Loh, N. H., Tor, S. B., Chua, C. K. (2016). Geometry dependence of microstructure and microhardness for selective electron beam-melted Ti–6Al–4V parts. Virtual and Physical Prototyping, 11 (3), 183–191. https://doi.org/10.1080/17452759.2016.1210483

- Ran, J., Jiang, F., Sun, X., Chen, Z., Tian, C., Zhao, H. (2020). Microstructure and Mechanical Properties of Ti-6Al-4V Fabricated by Electron Beam Melting. Crystals, 10 (11), 972. https://doi.org/10.3390/cryst10110972

- Wang, X., Chou, K. (2018). EBSD study of beam speed effects on Ti-6Al-4V alloy by powder bed electron beam additive manufacturing. Journal of Alloys and Compounds, 748, 236–244. https://doi.org/10.1016/j.jallcom.2018.03.173

- Sino-Euro Materials Technologies. Available at: https://en.c-semt.com/ti/

- Grabin, V. F. (1975). Osnovy metallovedeniya i termicheskoy obrabotki svarnyh soedineniy iz titanovyh splavov. Kyiv: Naukova dumka, 263.

- Zamkov, V. N. (Ed.) (1986). Metallurgiya i tehnologiya svarki titana i ego splavov. Kyiv: Naukova dumka, 240.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Vladyslav Matviichuk, Vladimir Nesterenkov, Olena Berdnikova

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.