Devising a technique for measuring torque of electric motors using machine vision

DOI:

https://doi.org/10.15587/1729-4061.2024.298513Keywords:

machine vision, rotational torque, measurement technique, electric motor parameters, dynamometric couplingAbstract

The object of research is the technique for measuring torques of electric motors. The main problem to be solved is the need to expand the range of informative parameters used in transmission torque converters of electric motors. This need arises from the design complications of placing the measuring devices directly on the motor shaft.

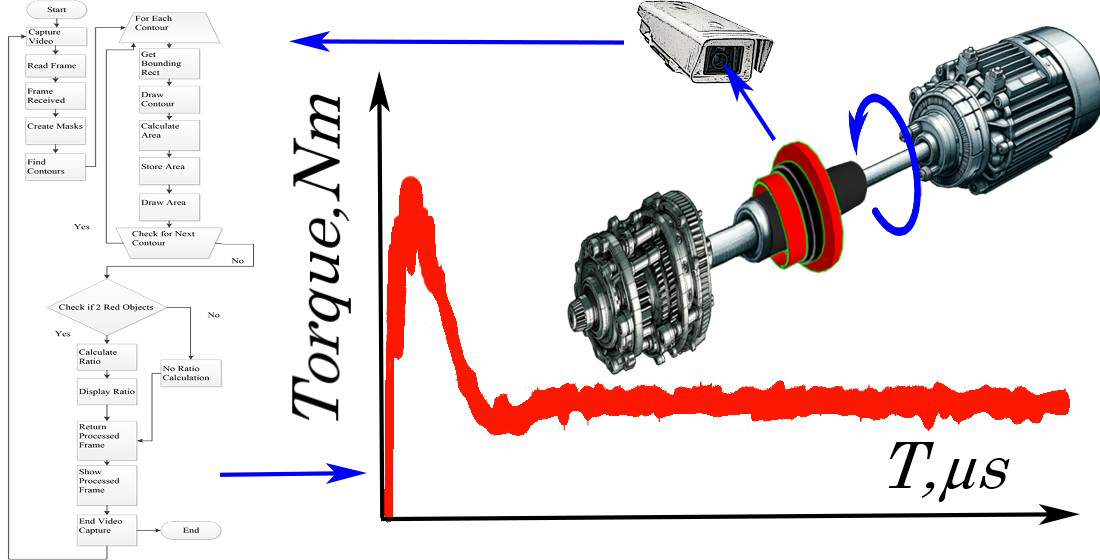

As part of the study, a system was designed for determining the torques of electric motors, which combines the procedure for assessing the load on the shaft and software tools for visually determining the quantitative characteristics of such a load using machine vision.

In order to acquire visual characteristics of the twisting of the shaft, a special coupling with an insert containing a liquid was designed. This coupling is able to change its shape in proportion to the load on electric motor shaft. The proposed visual control system, based on video information processing techniques, makes it possible to analyze changes in the shape of the coupling caused by the action of the torque.

Features of the application of the proposed measurement technique are that there is no need to place electronic components of the measuring transducer directly on the shaft. Due to the specified features, the proposed procedure provides a solution to the problems of torque measurement in aggressive environments, which is of crucial importance for the efficiency of some specific production processes.

Analysis of the visual characteristics of torque showed that the proposed approach could be applied in measuring transducers. At the same time, the results of testing the procedure confirmed that it requires the use of high-precision video recording equipment. This paves the way for the design of new, more modern, and reliable measurement systems that could be used in a wide range of industrial solutions

References

- Friswell, M. I., Penny, J. E. T., Garvey, S. D., Lees, A. W. (2010). Dynamics of Rotating Machines. Cambridge University Press. https://doi.org/10.1017/cbo9780511780509

- Sue, P., Wilson, D., Farr, L., Kretschmar, A. (2012). High precision torque measurement on a rotating load coupling for power generation operations. 2012 IEEE International Instrumentation and Measurement Technology Conference Proceedings. https://doi.org/10.1109/i2mtc.2012.6229149

- Guy, B. (2015). A1.3 - Measurement and traceability of torque on large mechanical drives. Proceedings SENSOR 2015. https://doi.org/10.5162/sensor2015/a1.3

- Zappalá, D., Bezziccheri, M., Crabtree, C. J., Paone, N. (2018). Non-intrusive torque measurement for rotating shafts using optical sensing of zebra-tapes. Measurement Science and Technology, 29 (6), 065207. https://doi.org/10.1088/1361-6501/aab74a

- Chen, L., Liang, W., Zhong, S., Zhang, Q., Lin, J., Nsengiyumva, W., Zeng, Q., Yu, Y. (2024). Novel contactless torque sensor based on optical coherence. Optics and Lasers in Engineering, 174, 107983. https://doi.org/10.1016/j.optlaseng.2023.107983

- Rafaq, M. S., Midgley, W., Steffen, T. (2024). A Review of the State of the Art of Torque Ripple Minimization Techniques for Permanent Magnet Synchronous Motors. IEEE Transactions on Industrial Informatics, 20 (1), 1019–1031. https://doi.org/10.1109/tii.2023.3272689

- Chen, W., Lan, C., Li, K., Yuan, F. (2023). Compensation and Control of Sinusoidal Torque Measurement Error. 2023 42nd Chinese Control Conference (CCC). https://doi.org/10.23919/ccc58697.2023.10240311

- Kakaley, D. E., Altieri, R. E., Buckner, G. D. (2020). Non-contacting measurement of torque and axial translation in high-speed rotating shafts. Mechanical Systems and Signal Processing, 138, 106520. https://doi.org/10.1016/j.ymssp.2019.106520

- Veyrat Durbex, A. F., Nachajon Schwartz, Y., Tacca, H. (2021). Solutions for Torque and Speed Measurement on Electric Machine Controllers Test Benches. Elektron, 5 (1), 20–31. https://doi.org/10.37537/rev.elektron.5.1.131.2021

- Zhang, C., Li, Z., Chen, J., Qiu, F., Na, S. (2021). Design and research of a novel non-contact vertical inductive torque sensor. Measurement, 177, 109252. https://doi.org/10.1016/j.measurement.2021.109252

- Gao, S., Feng, C., Zhang, X., Yu, Z., Yan, T., He, B. (2023). Unsupervised fault diagnosis framework for underwater thruster system using estimated torques and multi-head convolutional autoencoder. Mechanical Systems and Signal Processing, 205, 110814. https://doi.org/10.1016/j.ymssp.2023.110814

- Smyrnyi, M. F., Pitinov, D. H. (2019). Pat. No. 139522 UA. Bezkontaktnyi vymiriuvach krutnoho momentu, chastoty obertannia vala ta yoho pryskorennia. No. u201906456; declareted: 10.06.2019; published: 10.01.2020. Available at: https://base.uipv.org/searchINV/search.php?action=viewdetails&IdClaim=265073

- Chen, Z., Ge, S., Jiang, Y., Cheng, W., Zhu, Y. (2023). Refined modeling and experimental verification of a torque motor for an electro-hydraulic servo valve. Chinese Journal of Aeronautics, 36 (6), 302–317. https://doi.org/10.1016/j.cja.2023.01.014

- Zhong, S., Chen, L., Liang, W., Nsengiyumva, W., Yu, Y., Li, T., Zhang, Q. et al. (2024). Contactless torque sensors based on optical methods: A review. Optics and Lasers in Engineering, 173, 107832. https://doi.org/10.1016/j.optlaseng.2023.107832

- Nirala, A., Kumar, N., Bandhu Singh, D., Kumar singh, A., Kumar Sharma, S., Kumar Yadav, J. et al. (2020). Simulation analysis of composite helical spring for compression, torsional and transverse mode. Materials Today: Proceedings, 28, 2263–2267. https://doi.org/10.1016/j.matpr.2020.04.558

- Childs, P. R. N. (2014). Springs. Mechanical Design Engineering Handbook, 625–675. https://doi.org/10.1016/b978-0-08-097759-1.00015-0

- Bahaghighat, M., Abedini, F., Xin, Q., Zanjireh, M. M., Mirjalili, S. (2021). Using machine learning and computer vision to estimate the angular velocity of wind turbines in smart grids remotely. Energy Reports, 7, 8561–8576. https://doi.org/10.1016/j.egyr.2021.07.077

- Oleshko, T., Kvashuk, D., Heiets, I. (2019). Image recognition in unmanned aviation using modern programming languages. SN Applied Sciences, 1 (12). https://doi.org/10.1007/s42452-019-1739-y

- Oleshko, T., Kvashuk, D., Heiets, I. (2023). The Use of Machine Vision in the Diagnosis of Ripening Strawberries. Artificial Intelligence. https://doi.org/10.5772/intechopen.110894

- Kvasnikov, V. P., Bratchenko, H. D., Kvashuk, D. M. (2023). Estimation of measuring uncertainty of electric motors torques using the theory of fuzzy sets. Collection of scientific works of the Odesa State Academy of Technical Regulation and Quality, 1 (22), 23–34. https://doi.org/10.32684/2412-5288-2023-1-22-23-34

- Herasimov, S., Pavlii, V., Tymoshchuk, O., Yakovlev, M. Yu., Khaustov, D. Ye. et al. (2019). Testing Signals for Electronics: Criteria for Synthesis. Journal of Electronic Testing, 35 (3), 349–357. https://doi.org/10.1007/s10836-019-05798-9

- Shalobanov, S. V., Shalobanov, S. S. (2023). Algorithm For Searching For Multiple Structural Defects In Automatic Control Systems Using Sensitivity Functions. 2023 International Conference on Industrial Engineering, Applications and Manufacturing (ICIEAM). https://doi.org/10.1109/icieam57311.2023.10139270

- de Souza, G. F. M., Caminada Netto, A., de Andrade Melani, A. H., de Carvalho Michalski, M. A., da Silva, R. F. (2022). Engineering systems fundamentals. Reliability Analysis and Asset Management of Engineering Systems, 55–90. https://doi.org/10.1016/b978-0-12-823521-8.00012-8

- Demir, H., Çilingir Süngü, İ., Keles, İ. (2023). Investigating the Laplace Transform Method’s Efficiency to a Simple Engineering Problem. Turkish Journal of Mathematics and Computer Science, 15 (2), 326–333. https://doi.org/10.47000/tjmcs.1378857

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Volodymyr Kvasnikov, Dmytro Kvashuk, Mykhailo Prygara, Oleksii Shelukha, Kateryna Molchanova

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.